Ladle furnace (LF) refining technology

A process, converter blowing technology, applied in the field of LF furnace refining process, to achieve the effect of reducing consumption, saving costs, and less chemical input

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

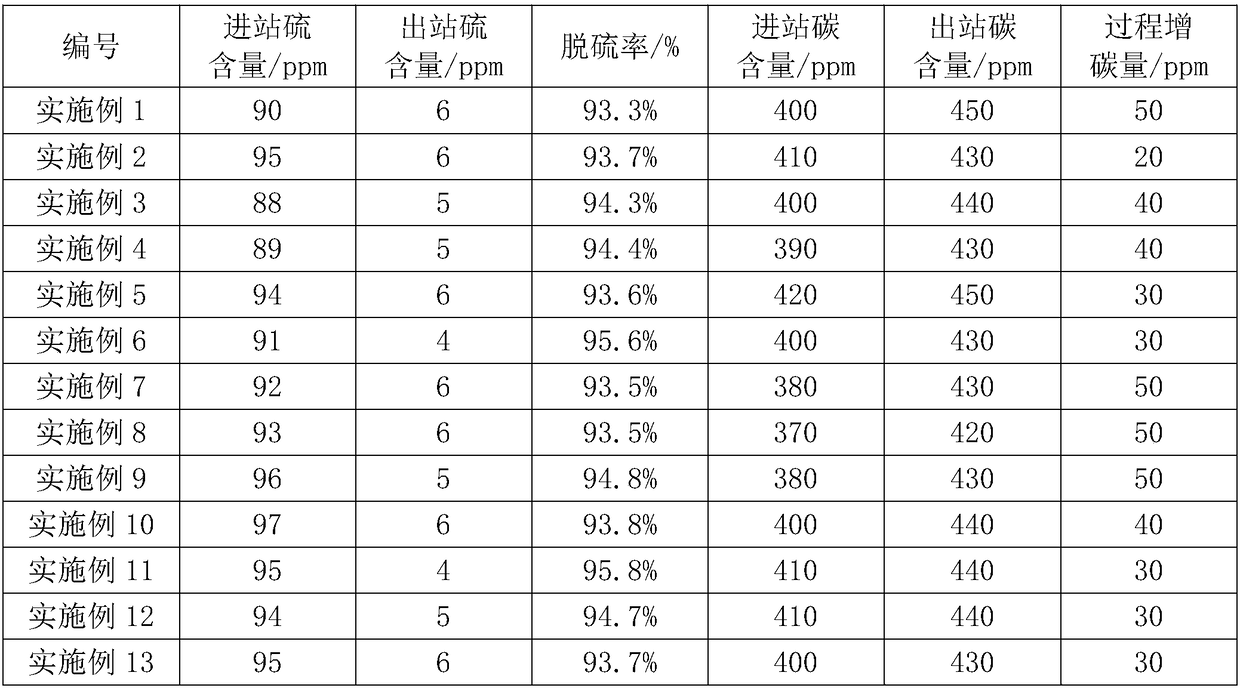

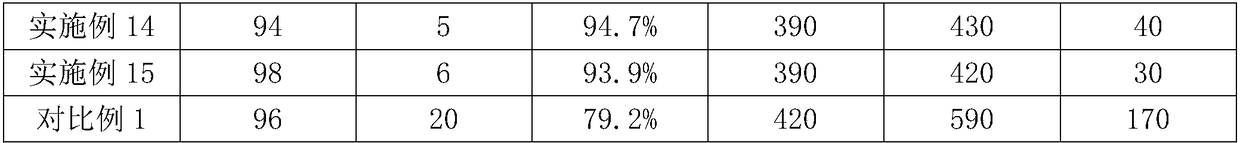

Examples

Embodiment 1

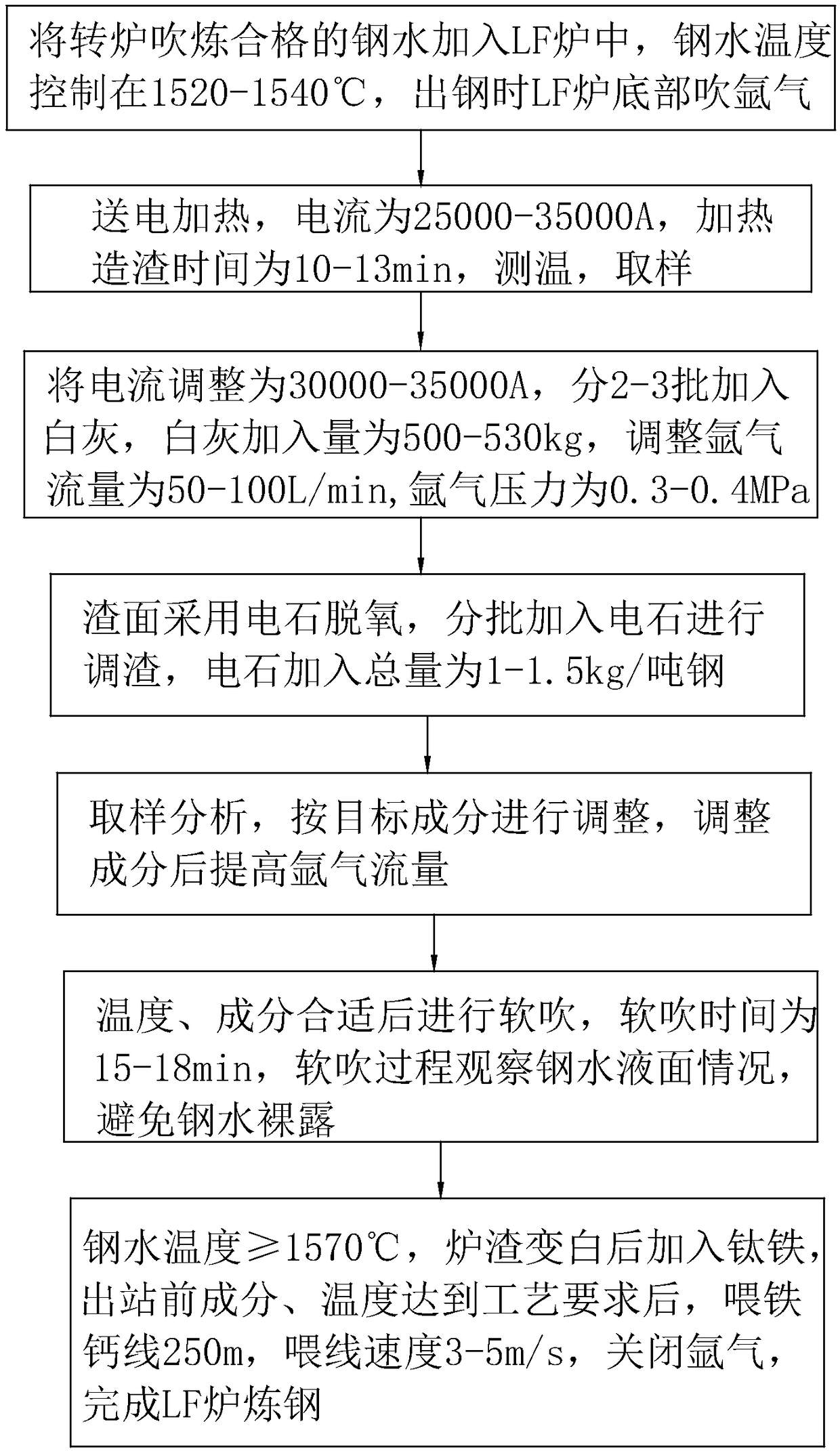

[0029] Embodiment 1: as figure 1 As shown, a LF furnace refining process includes the following steps: the initial carbon and sulfur content of molten steel entering the LF furnace is C: 0.04%, S: 0.009%;

[0030] Step 1: Put the molten steel qualified by converter blowing into the LF furnace, the temperature of the molten steel is controlled at 1520°C, the composition of the molten steel is C0.37-0.42%, Si0.10-0.17%, Mn0.5-0.6%, P≤0.025 %, T[O]≤30ppm, argon gas is blown at the bottom of the LF furnace when tapping, the flow rate of argon gas is 100L / min, and the pressure of argon gas is 0.3MPa;

[0031] Step 2, power transmission and heating, the current is 25000A, the heating slagging time is 10min, the argon flow rate is 250L / min, the argon pressure is 0.3MPa during the slagging process, temperature measurement and sampling;

[0032] Step 3, adjust the current to 30000A, add lime in 2-3 batches, the amount of lime added is 500kg, adjust the argon flow rate to 50L / min, argo...

Embodiment 2

[0037] Embodiment 2: A LF furnace refining process, comprising the following steps: the initial carbon and sulfur content of molten steel entering the LF furnace is C: 0.041%, S: 0.0095%;

[0038] Step 1: Put the molten steel qualified by converter blowing into the LF furnace, the temperature of the molten steel is controlled at 1530°C, the composition of the molten steel is C0.37-0.42%, Si0.10-0.17%, Mn0.5-0.6%, P≤0.025 %, T[O]≤30ppm, argon gas is blown at the bottom of the LF furnace when tapping, the flow rate of argon gas is 125L / min, and the pressure of argon gas is 0.35MPa;

[0039] Step 2, power transmission and heating, the current is 25000A, the heating slagging time is 10min, the argon flow rate is 250L / min, the argon pressure is 0.3MPa during the slagging process, temperature measurement and sampling;

[0040] Step 3, adjust the current to 30000A, add lime in 2-3 batches, the amount of lime added is 500kg, adjust the argon flow rate to 50L / min, argon pressure to 0.3MP...

Embodiment 3

[0045] Embodiment 3: a LF furnace refining process, comprising the following steps: the initial carbon and sulfur content of molten steel entering the LF furnace is C: 0.04%, S: 0.0088%;

[0046] Step 1: Put the molten steel qualified by converter blowing into the LF furnace, the temperature of the molten steel is controlled at 1540°C, the composition of the molten steel is C0.37-0.42%, Si0.10-0.17%, Mn0.5-0.6%, P≤0.025 %, T[O]≤30ppm, argon gas is blown at the bottom of the LF furnace when tapping, the flow rate of argon gas is 150L / min, and the pressure of argon gas is 0.4MPa;

[0047] Step 2, power transmission and heating, the current is 25000A, the heating slagging time is 10min, the argon flow rate is 250L / min, the argon pressure is 0.3MPa during the slagging process, temperature measurement and sampling;

[0048] Step 3, adjust the current to 30000A, add lime in 2-3 batches, the amount of lime added is 500kg, adjust the argon flow rate to 50L / min, argon pressure to 0.3MP...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com