Floor radiant heating construction method

A technology of radiant heating and construction methods, applied in heating methods, hot water central heating systems, sustainable buildings, etc., can solve the problems of increasing user economic pressure, occupying a large room, and uneven indoor temperature, etc., to achieve enhanced thermal insulation effect , low operating costs, and slow indoor temperature changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

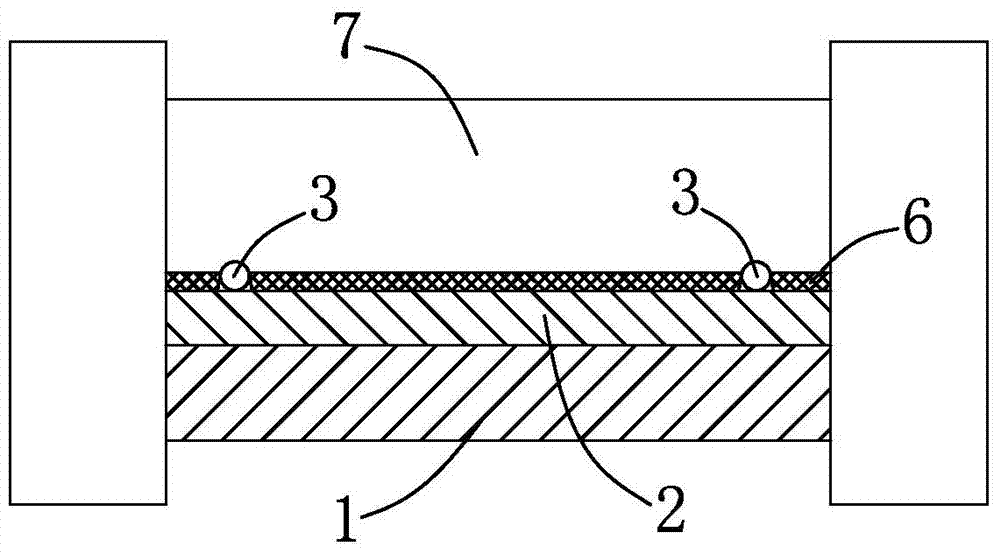

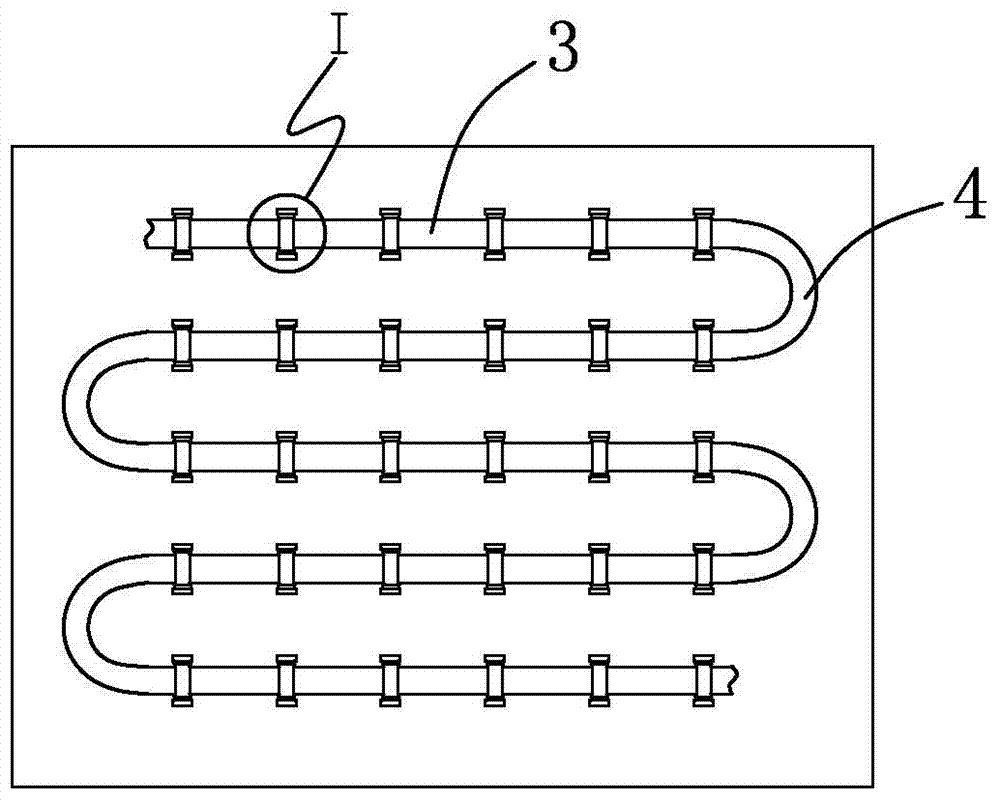

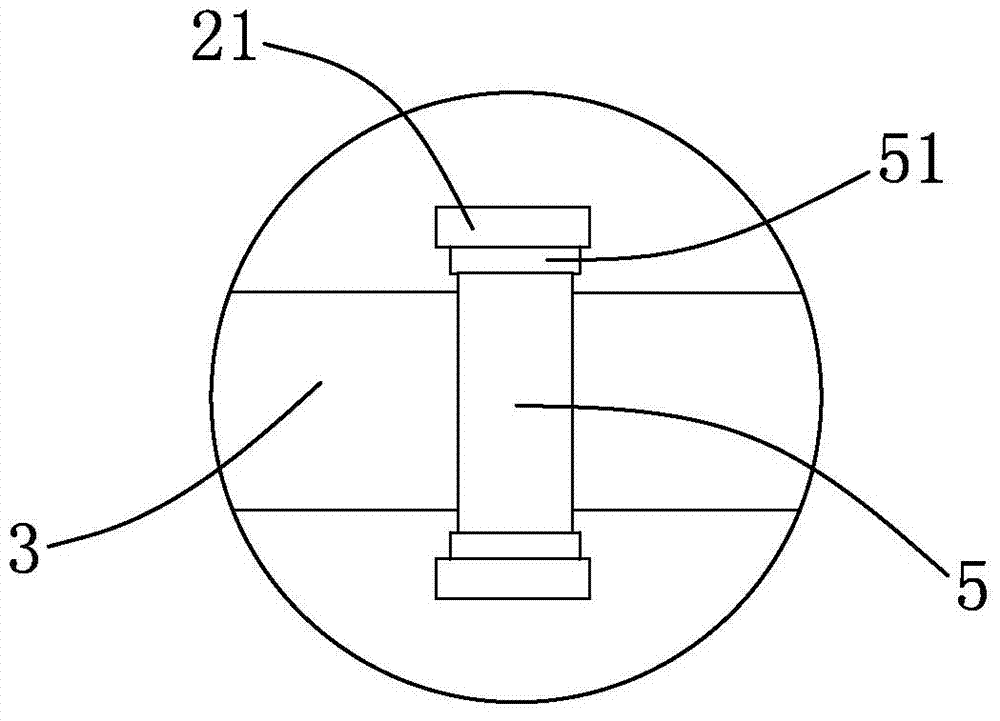

[0027] This construction method comprises the following steps:

[0028] (a) Structural layer leveling:

[0029] The elevation review and leveling review of the structural layer 1 in the floor heating construction area of each floor adopts the infrared lead wire measurement standard to strictly control the flatness of the surface. When the ground radiation heating project is used for construction on the floor, carefully press and wipe. The flatness is allowed The error should meet the requirements of the concrete or mortar floor, and the allowable deviation of leveling is 10mm. At the same time, the garbage, floating ash and attachments on the floor should be removed, and the floor should be cleaned and kept dry. If the site does not have construction conditions: if the ground is not flat enough, the ground elevation does not meet the requirements, and there are materials piled on the ground, etc., the construction of the floor heating system should not be carried out.

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com