Tunnel anti-icing composite plate based on phase-change material

A phase change material and composite plate technology, applied in tunnels, tunnel linings, wellbore linings, etc., can solve the problems of general effect, complicated installation, long construction period, etc., achieve uniform ice prevention and melting, reduce operating costs, and long service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Embodiments of the present invention are described in detail below.

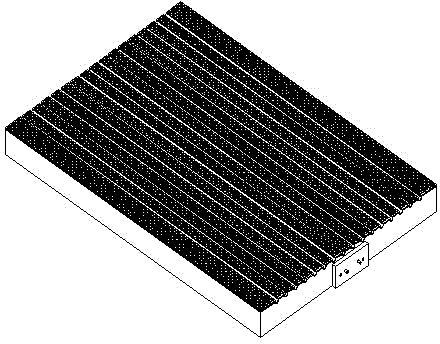

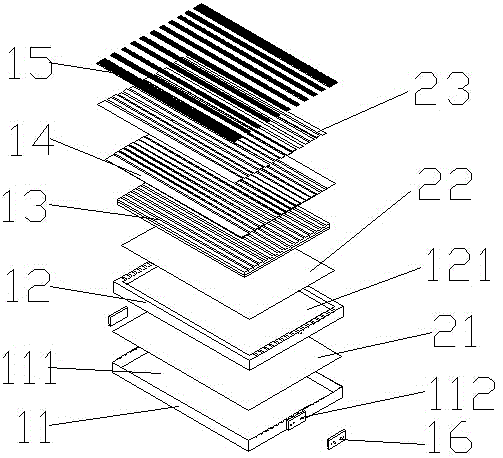

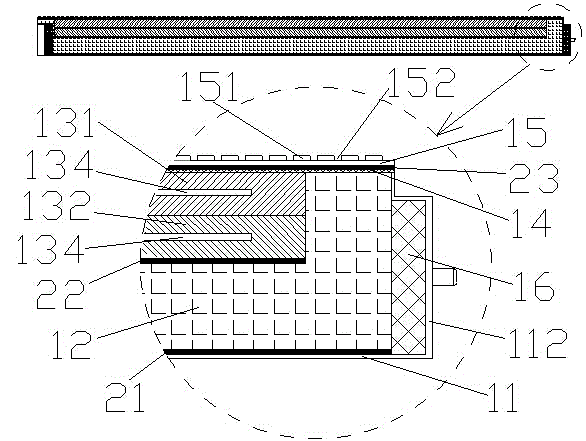

[0022] Such as figure 1 , figure 2 and image 3 As shown, the tunnel anti-icing composite plate based on phase change material in the present invention is composed of six parts, which are outer shell 11, insulation layer 12, phase change material heat storage module 13, waterproof layer 14, deflector 15, Terminal 16. The outer casing 11 is a rectangular box structure, with an opening 111 on the upper side to sequentially put in the insulation layer 12, the phase change material heat storage module 13, the waterproof layer 14, and the deflector 15; the outer casing 11 is provided with terminals on both sides for assembly Groove 112, to put terminal 16 into. The thermal insulation layer 12 is provided with a rectangular groove 121 to accommodate the phase change material heat storage module 13 .

[0023] In this example, if figure 2 , the thermal insulation layer 12 is placed in the opening 121 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com