A dry-process desulfurization and denitrification catalyst replacement device and method without shutdown

A denitration catalyst and dry desulfurization technology are applied in the field of non-stop replacement devices for dry desulfurization and denitration catalysts, which can solve the problems of easily damaged reactors, cumbersome replacement process, and prolonged production cycle, and achieve fast replacement, avoid gas leakage, The effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

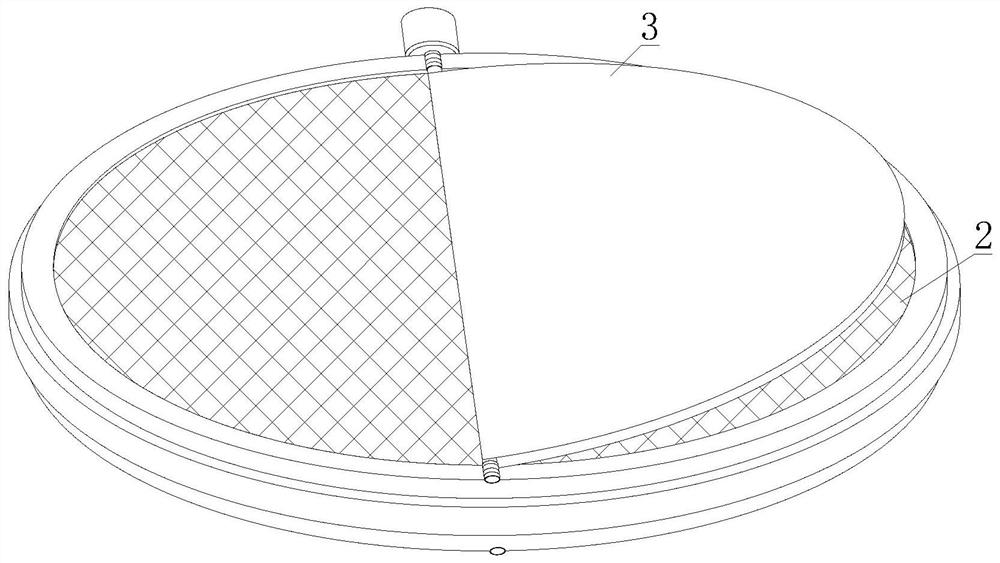

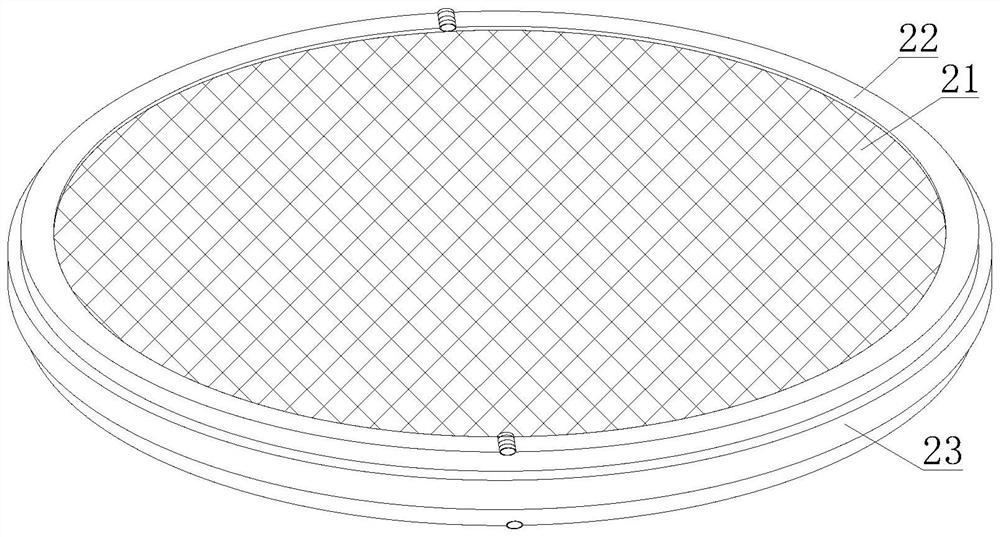

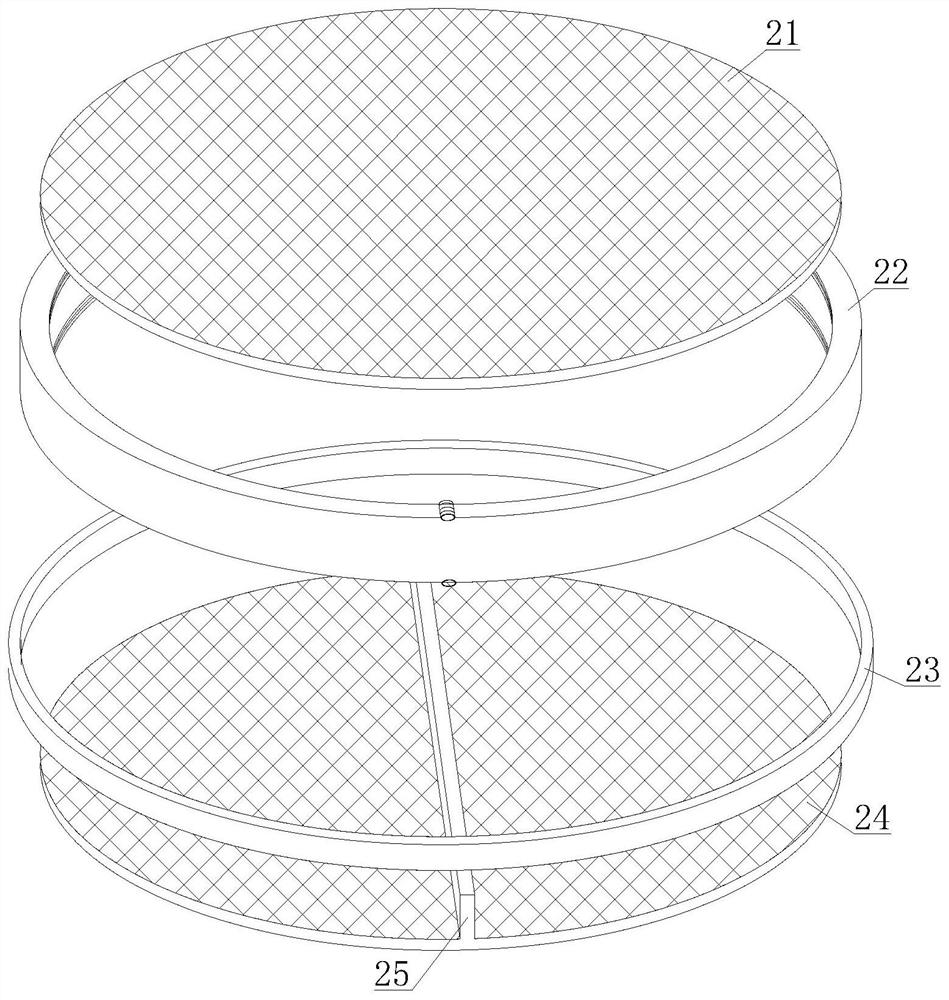

[0032] see Figure 1-4 , a non-stop replacement device for dry desulfurization and denitration catalyst, comprising a guiding mechanism 1, a catalyst filling tank 2, a baffle 3 and a filling system 4, the filling system 4 is connected with the guiding mechanism 1, and the guiding mechanism 1 is located inside the catalyst filling tank 2 , the upper and lower ends of the catalyst filling tank 2 are equipped with baffles 3, the baffles 3 include a rotating motor 31, a rotating shaft 32 and a semicircular plate 33, the two ends of the rotating shaft 32 are rotatably connected with a mounting ring 22, and the rotating shaft 32 A semi-circular plate 33 is fixedly connected to the middle of the rotary shaft 32, and a rotary motor 31 is connected to one end of the rotary shaft 32. The rotary motor 31 is installed on the outside of the reactor, and the rotary motor 31 adopts a high-temperature resistant explosion-proof motor. The semicircular plate 33 is perpendicular to the upper gri...

Embodiment 2

[0039] see Figure 7 , a non-stop replacement device for dry desulfurization and denitration catalyst, comprising a guiding mechanism 1, a catalyst filling tank 2, a baffle 3 and a filling system 4, the filling system 4 is connected with the guiding mechanism 1, and the guiding mechanism 1 is located inside the catalyst filling tank 2 , the upper and lower ends of the catalyst filling tank 2 are equipped with baffles 3, the baffles 3 include a rotating motor 31, a rotating shaft 32 and a semicircular plate 33, the two ends of the rotating shaft 32 are rotatably connected with a mounting ring 22, and the rotating shaft 32 A semi-circular plate 33 is fixedly connected to the middle of the rotary shaft 32, and a rotary motor 31 is connected to one end of the rotary shaft 32. The rotary motor 31 is installed on the outside of the reactor, and the rotary motor 31 adopts a high-temperature resistant explosion-proof motor. The semicircular plate 33 is parallel to the upper grid plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com