Packaged food packaging system

A food packaging and food technology, applied in packaging, transportation packaging, packaging protection, etc., can solve the problems of integration of disinfection and sterilization, automatic packing and automatic transportation, low degree of automation, low production efficiency, etc., to reduce Potential food safety hazards, high degree of automation, and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

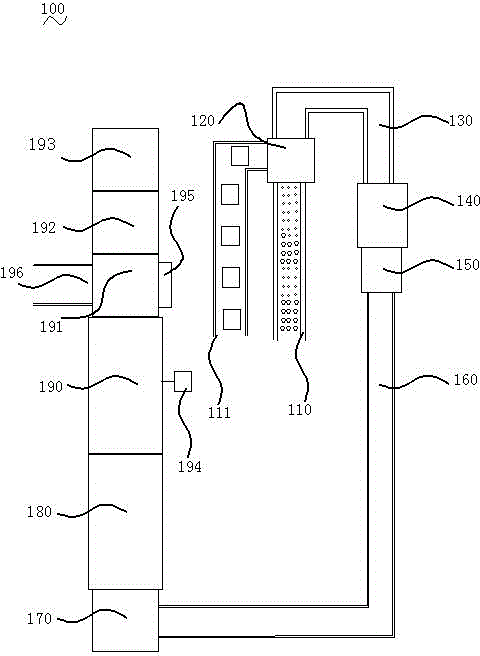

[0023] Such as figure 1 As shown, it is a schematic diagram of a bagged food packaging system 100 according to an embodiment of the present invention.

[0024] A bagged food packaging system 100, comprising a feeding rail 110, a packaging bag opening and closing mechanism 120, a bag outlet rail 130, a tray loading mechanism 140, a tray stacking mechanism 150, a tray transfer rail 160, a bag unloading mechanism 170, Sterilization mechanism 180, drying mechanism 190, bag sorting mechanism 191, box packing mechanism 192 and automatic box sealing mechanism 193. Feeding track 110, packaging bag opening and closing mechanism 120, bag discharging track 130, tray loading mechanism 140, tray stacking mechanism 150, and tray transfer track 160 are located in Room B, and the bag unloading mechanism 170, sterilization mechanism 180, and drying mechanism 190 , the bag sorting mechanism 191, the case packing mechanism 192, and the automatic case sealing mechanism 193 are located in Room A,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com