Preparation process of convenient rice

A production process and technology of instant rice, applied in food preparation, application, food science, etc., can solve the problems of short rehydration time, edible quality and low production cost, and achieve the effect of shortening rehydration time and improving gelatinization degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

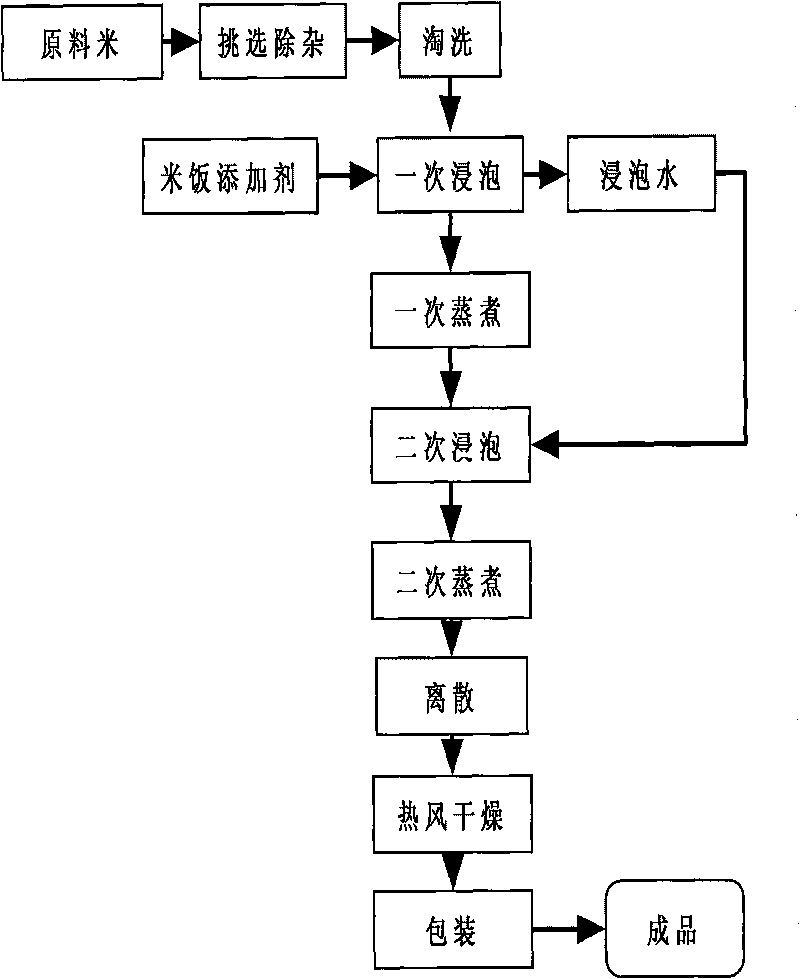

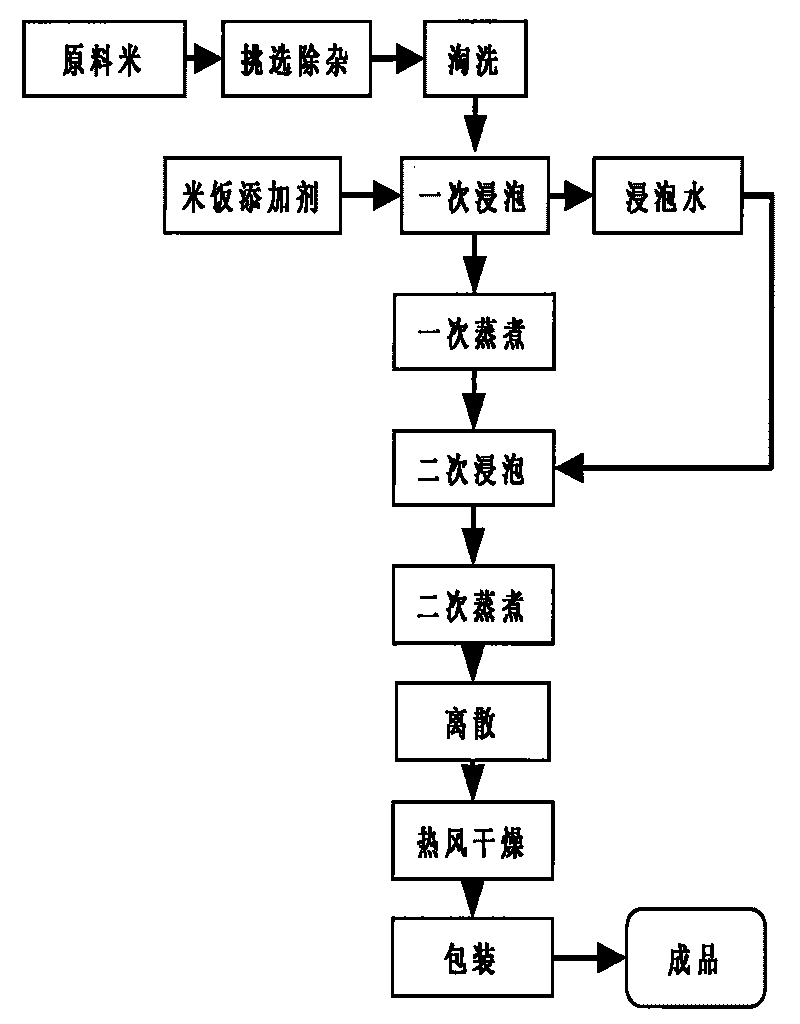

[0020] A kind of manufacture craft of instant rice, see figure 1 , including the following steps:

[0021] A, washing rice: select 5kg of raw material rice for removing impurities, and wash the rice cleanly to remove powdery impurities adhering to the surface of the rice;

[0022] B, soaking for the first time: soak the cleaned rice for the first time at 30°C in an aqueous solution containing 0.4% citric acid, 0.2% beta cyclodextrin and 0.2% sucrose fatty acid ester, soak The time is 60 minutes, so that the rice absorbs water and swells, and the water content of the drained water reaches 29%;

[0023] C. The first cooking: at 100°C, cook for 10 minutes;

[0024] D. The second soaking: In an aqueous solution containing 0.2%-0.6% citric acid, 0.1%-0.3% β-cyclodextrin and 0.1%-0.3% sucrose fatty acid ester, conduct the second soaking at 50°C Soaking, the soaking time is 20 minutes, and the water content of the drained water reaches 60%;

[0025] E. The second cooking: cooking...

Embodiment 2

[0030] The aqueous solution formula is 0.2% citric acid, 0.1% β-cyclodextrin, 0.1% sucrose fatty acid ester and 99.6% water;

[0031] 35°C for the first immersion, the immersion time is 70 minutes,

[0032] The first cooking: cooking at 100°C for 15 minutes;

[0033] 55°C for the second immersion, the immersion time is 25 minutes,

[0034] The second cooking: cooking at 100°C for 15 minutes;

[0035] Other conditions are with embodiment 1.

Embodiment 3

[0037] The aqueous solution formula is 0.6% citric acid, 0.3% beta cyclodextrin, 0.3% sucrose fatty acid ester and 98.8% water;

[0038] 25°C for the first immersion, the immersion time is 50 minutes,

[0039] The first cooking: cooking at 100°C for 8 minutes;

[0040] 45°C for the second immersion, the immersion time is 15 minutes,

[0041] The second cooking: cooking at 100°C for 8 minutes;

[0042] Other conditions are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com