Original-fragrant camellia oil rich in active components and producing method thereof

An active ingredient and a production method technology, applied in the field of woody vegetable oil and its production, can solve the problems of unsafe, inability to retain rich flavor and nutritional active ingredients, etc., and achieve the effects of low cost, rich original fragrance, and simple method and process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] A preparation method of the original fragrant camellia oil rich in active ingredients, which mainly includes the following process steps:

[0052] one. Preparation of pressed camellia oil raw materials

[0053] Selection: Take 1000KG of fresh camellia oleifera fruit, remove immature, worm-eaten, dull, sprouting, moldy, heat-damaged, heterogeneous seeds and other low-quality camellia oleifera fruit, and get 840KG of high-quality fresh camellia oleifera fruit;

[0054] Retting: Place the above-mentioned high-quality fresh camellia oleifera fruit indoors or pile them up for 4 to 7 days in a place where the rain cannot reach them.

[0055] Drying and shelling: Put the retting Camellia oleifera fruit on the drying field (choose sunny days) and spread it out in the sun (turn over frequently). After 3 to 4 days, the camellia oleifera fruit shell (also called preserved camellia oleifera fruit) cracks on its own, and most of the Camellia oleifera seeds come out by themselves, ...

Embodiment 2-6

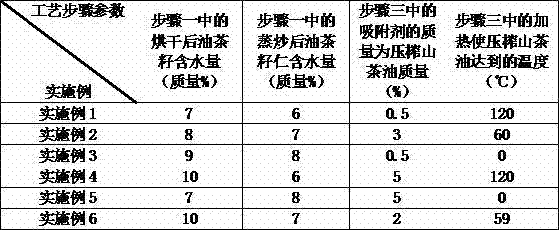

[0074] Embodiment 2-6 is except that process parameter is different from embodiment 1, and its manufacturing process step is identical with embodiment 1, and following table 1 has listed process parameter in each embodiment in detail:

[0075] Table 1

[0076]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com