Blast furnace mud gun with low content of benzopyrene

A technology of benzopyrene content, applied in blast furnaces, blast furnace details, blast furnace parts and other directions, can solve the problems of serious pollution and high content of benzopyrene, and achieve enhanced operating performance, reduced amount of harmful gases, and improved durability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

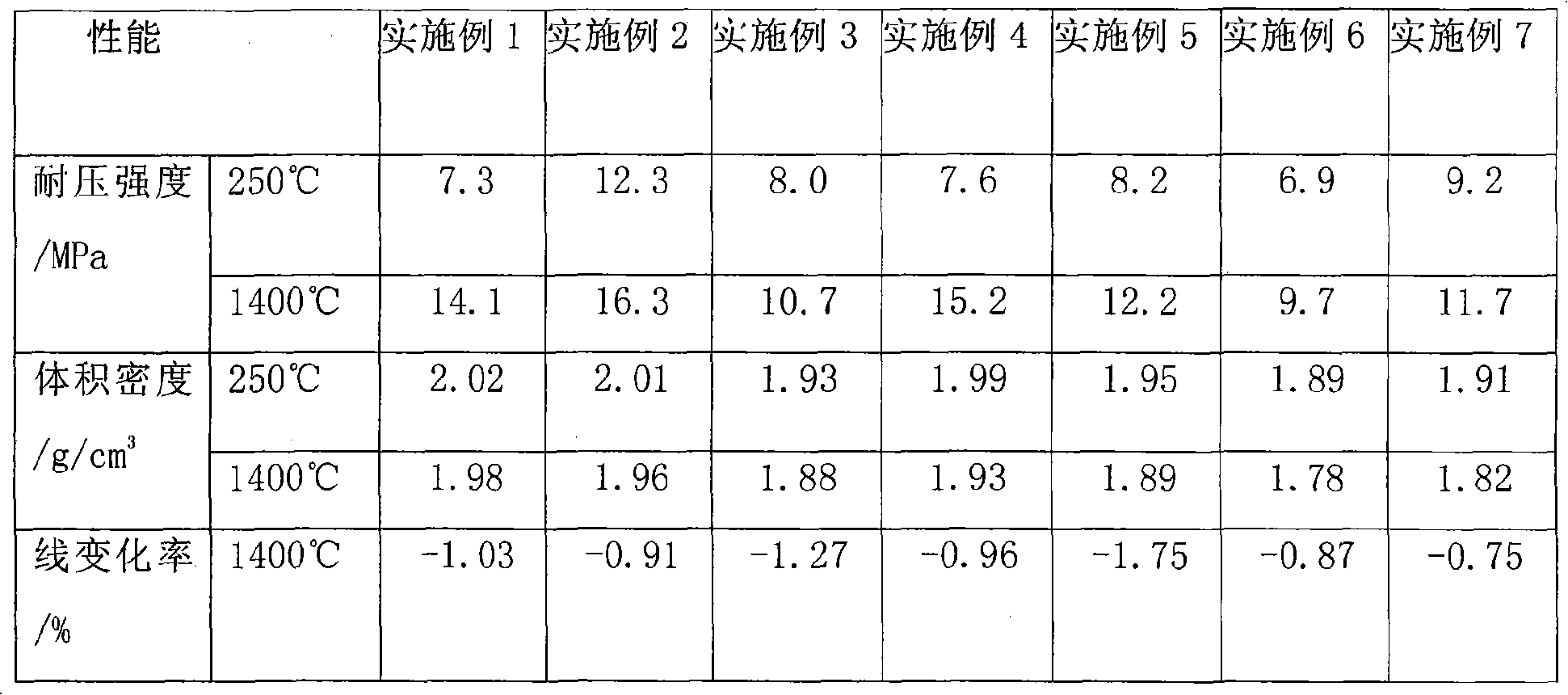

Examples

Embodiment 1

[0015] A kind of blast furnace clay with low benzopyrene content: 10 parts of carbon-containing resin with a fixed carbon content of 85% by mass, and its benzopyrene content is 950ppm; the components and parts by weight are: 8 parts of high alumina bauxite, 37 parts of corundum, 5 parts of silicon carbide, 10 parts of clay, 8 parts of coke powder, 2 parts of ferrosilicon nitride and 5 parts of sericite are uniformly mixed and the weight part of the refractory matrix is 75 parts; It is: 3 parts of denatured alcohol, 5 parts of ethylene glycol, and the parts by weight of the carbon-containing resin solvent are 8 parts.

[0016] Add 8 parts by weight of carbon-containing resin solvent to the above-mentioned refractory matrix with 75 parts by weight, mix and stir evenly, and then add 10 parts of carbon-containing resin with a fixed content of 85% by mass Mix and roll evenly, and pack for use after extruding mud strips through a mud extruder.

Embodiment 2

[0018] A blast furnace clay with low benzopyrene content: 15 parts of carbon-containing resin with a fixed carbon content of 50% by mass, and its benzopyrene content is 760ppm; the components and parts by weight are: 6 parts of high alumina bauxite, 30 parts of corundum, 12 parts of silicon carbide, 7 parts of clay, 15 parts of coke powder, 5 parts of ferrosilicon nitride and 7 parts of sericite are uniformly mixed and the weight part of the refractory matrix is 82 parts; It is: 0.8 parts of industrial alcohol, 1 part of ethylene glycol, and the weight part of the carbon-containing resin solvent is 1.8 parts.

[0019] Add 1.8 parts by weight of carbon-containing resin solvent to the above-mentioned refractory matrix with 82 parts by weight, mix and stir evenly, and then add 15 parts of carbon-containing resin with a fixed content of 50% by mass Mix and roll evenly, and pack for use after extruding mud strips through a mud extruder.

Embodiment 3

[0021] A blast furnace clay with low benzopyrene content: 25 parts of carbon-containing resin with a fixed carbon content of 30% by mass, and its benzopyrene content is 850ppm; the components and parts by weight are: 20 parts of high alumina bauxite, 32 parts of corundum, 18 parts of silicon carbide, 3 parts of clay, 12 parts of coke powder and 9 parts of sericite are uniformly mixed to form a refractory matrix of 94 parts by weight; the components and parts by weight are: industrial alcohol 0.01 part, 0.05 part of ethylene glycol constitutes 0.06 part by weight of the carbon-containing resin solvent.

[0022] Add 0.06 parts by weight of carbon-containing resin solvent to the above-mentioned refractory matrix with 94 parts by weight, mix and stir evenly, and then add 25 parts of carbon-containing resin with a fixed content of 30% by mass Mix and roll evenly, and pack for use after extruding mud strips through a mud extruder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com