Natural vegetable and fruit fermented beverage

A technology for fermenting beverages, fruits and vegetables, applied in the field of food and beverages, can solve problems such as insufficient fermentation of products, achieve the effects of promoting growth and metabolic process, good water solubility, enhancing nutrition and functionality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

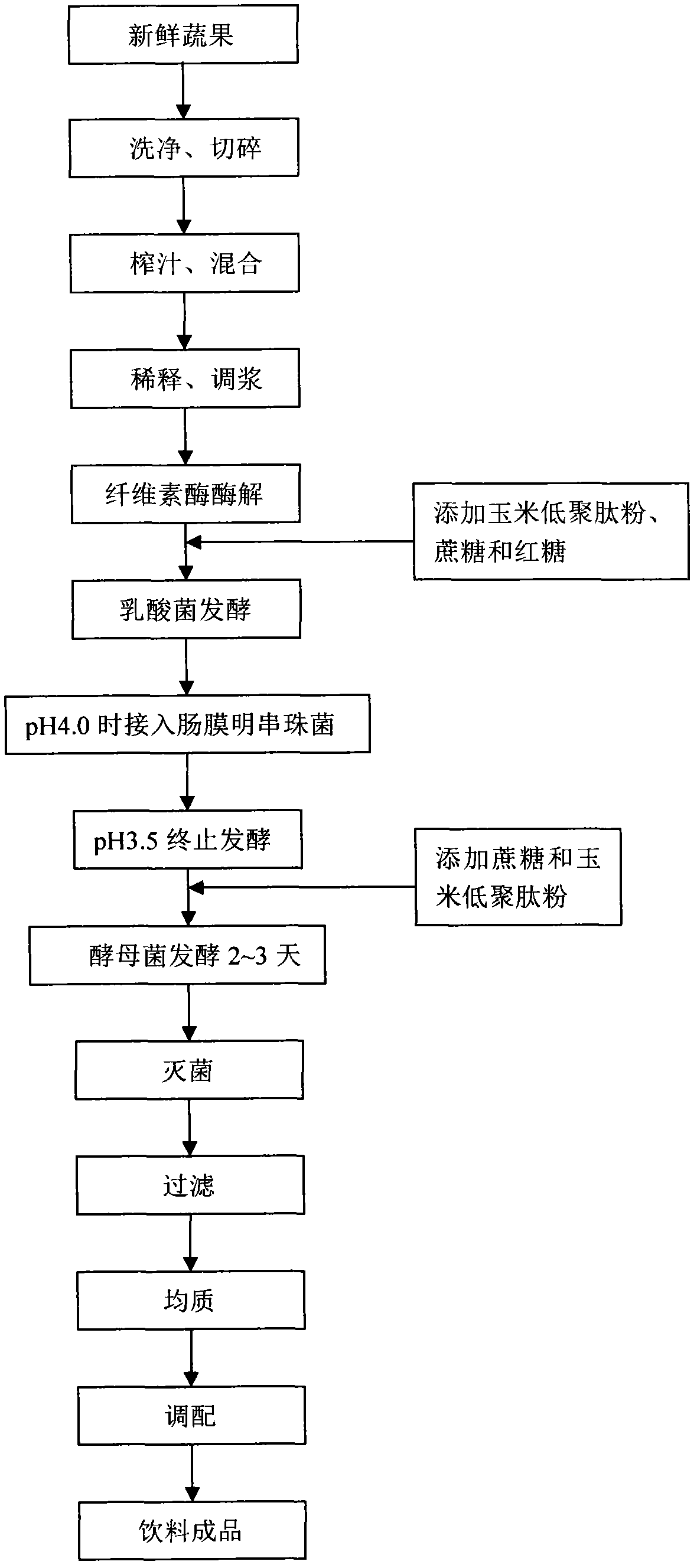

Method used

Image

Examples

Embodiment 1

[0036] Take 1kg each of fresh carrots, tomatoes, cucumbers, shiitake mushrooms, white melons, apples, oranges, and grapes, wash, peel, and cut into pieces, squeeze the juice, mix the vegetable juices, and add 8% pure water to dilute the paste , after mixing evenly, add 0.2% cellulase, and enzymatically hydrolyze at 45°C for 5h. After the enzymolysis, 3% corn oligopeptide powder (w / v) was added, and 7.5% brown sugar and white sugar were added, sterilized at high temperature and cooled to 32°C. Add Streptococcus thermophilus, Lactobacillus delbrueckii subsp. bulgaricus, Lactobacillus acidophilus, Bifidobacterium and Lactobacillus casei 4U / 1000L (adding in the same mass ratio), ferment at a temperature of 32°C, when the pH reaches 4.0; 0.3% calcium carbonate (w / w) was added, and then 2U / 1000L of Leuconostoc enterococcus was inserted, and the fermentation was continued at a temperature of 30°C. When the pH reached 3.5, 1% sucrose (w / v) and 1% corn oligopeptide powder (w / v) were a...

Embodiment 2

[0040] Take 1kg each of fresh Chinese cabbage, white radish, purple cabbage, oyster mushroom, pineapple, cantaloupe, pear, and grapefruit, wash, peel, cut into pieces, squeeze the juice, mix the vegetable juice, and add 5% volume pure water Dilute the slurry, mix well, add 0.05% cellulase, and enzymatically hydrolyze at 43°C for 2 hours. After the enzymolysis, add 2% corn oligopeptide powder (w / v), add 10% brown sugar and 5% white sugar respectively, sterilize at high temperature and cool to 30°C. Add Lactobacillus acidophilus, Lactobacillus casei and Bifidobacterium 3U / 1000L (adding in the same mass ratio), ferment at a temperature of 35°C, when the pH reaches 4.0; add 0.5% calcium carbonate (w / w), and then inoculate 3U / 1000L of Leuconostoc enteroenteritis was introduced, and the fermentation was continued at a temperature of 35°C. When the pH reached 3.5, 1.5% sucrose (w / v) and 0.5% corn oligopeptide powder (w / v) were added, high temperature sterilized and cooled. Add 0.12...

Embodiment 3

[0044] Take 1kg each of fresh celery, cabbage, purple radish, black fungus, watermelon, papaya, lemon, and kiwi, wash, peel, cut into pieces, squeeze the juice, mix the vegetable juice, add 10% volume pure water to dilute Slurry, mix evenly, add 0.1% cellulase, and enzymatically hydrolyze at 47°C for 3 hours. After the enzymolysis, add 3% corn oligopeptide powder (w / v), add 5% brown sugar and 10% white sugar respectively, sterilize at high temperature and cool to 35°C. Add Streptococcus thermophilus and Lactobacillus delbrueckii subspecies bulgaricus 2U / 1000L (adding in the same mass ratio), ferment at a temperature of 30°C, when the pH reaches 4.0; add 0.2% calcium carbonate (w / w), and then inoculate Enter Leuconostoc enterococci 1U / 1000L, and continue fermentation at a temperature of 25°C. When the pH reached 3.5, 0.5% sucrose (w / v) and 1.5% corn oligopeptide powder (w / v) were added, high temperature sterilized and cooled. Add 0.1% highly active dry yeast, ferment at 25°C ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com