Modified PP automobile special material and production method thereof

A special material, automobile technology, applied in the field of formula design of modified PP automobile special material, can solve the problems of post-crystal dimensional stability, poor color adhesion, poor color stability, etc., to solve the problem of paint adhesion, flame retardant Good properties and good color adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

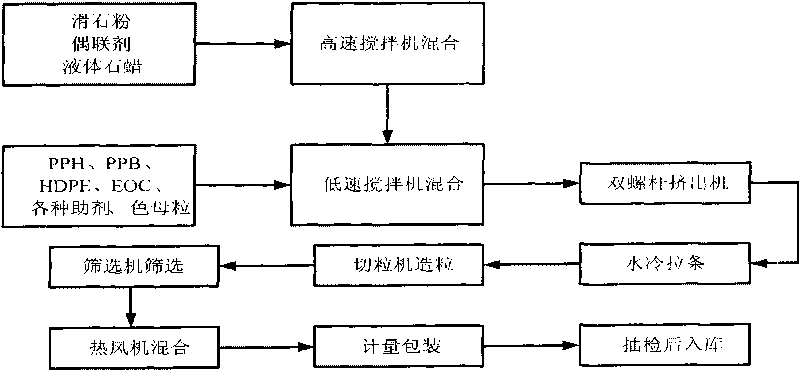

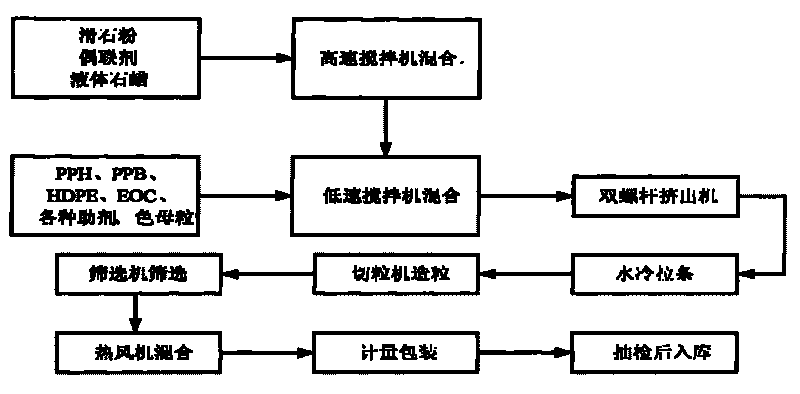

Method used

Image

Examples

Embodiment 1

[0052] The formula of active talc powder is: 1250 mesh talc powder 20kg, silane coupling agent 0.2kg, liquid paraffin 0.08kg;

[0053] Main formula: homopolypropylene PPH 5kg, copolymerized polypropylene PPB 95kg, HDPE 5kg, EOC 2kg, PP-g-MAH 2kg, antioxidant 0.2kg, anti-ultraviolet agent 0.1kg, black masterbatch 2kg;

Embodiment 2

[0054] Formulation embodiment 2;

[0055] 1250 mesh talcum powder 30kg, silane coupling agent 0.3kg, liquid paraffin 0.1kg;

[0056] Main formula: homopolypropylene PPH 8kg, copolymerized polypropylene PPB 92kg, HDPE 8kg, EOC 4kg, PP-g-MAH 6kg, antioxidant 0.3kg, anti-ultraviolet agent 0.2kg, black masterbatch 2kg;

Embodiment 3

[0058] 1250 mesh talcum powder 40kg, silane coupling agent 0.4kg, liquid paraffin 0.15kg;

[0059] Main formula: homopolypropylene PPH 10kg, copolymerized polypropylene PPB 90kg, HDPE 10kg, EOC 8kg, PP-g-MAH 8kg, antioxidant 0.3kg, anti-ultraviolet agent 0.3kg, black masterbatch 2kg;

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com