Tile with thermal shock resistance, pressure resistance and acid resistance as well as its manufacturing method

A technology of thermal shock resistance and pressure resistance, which is applied in the field of ceramic tiles and its production, can solve the problems of increasing the corrosion area of strong acid medium, failing to meet technical requirements, reducing acid corrosion resistance, etc., achieving good chemical stability and excellent resistance to rapid cooling Rapid heat performance, the effect of overcoming poor corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

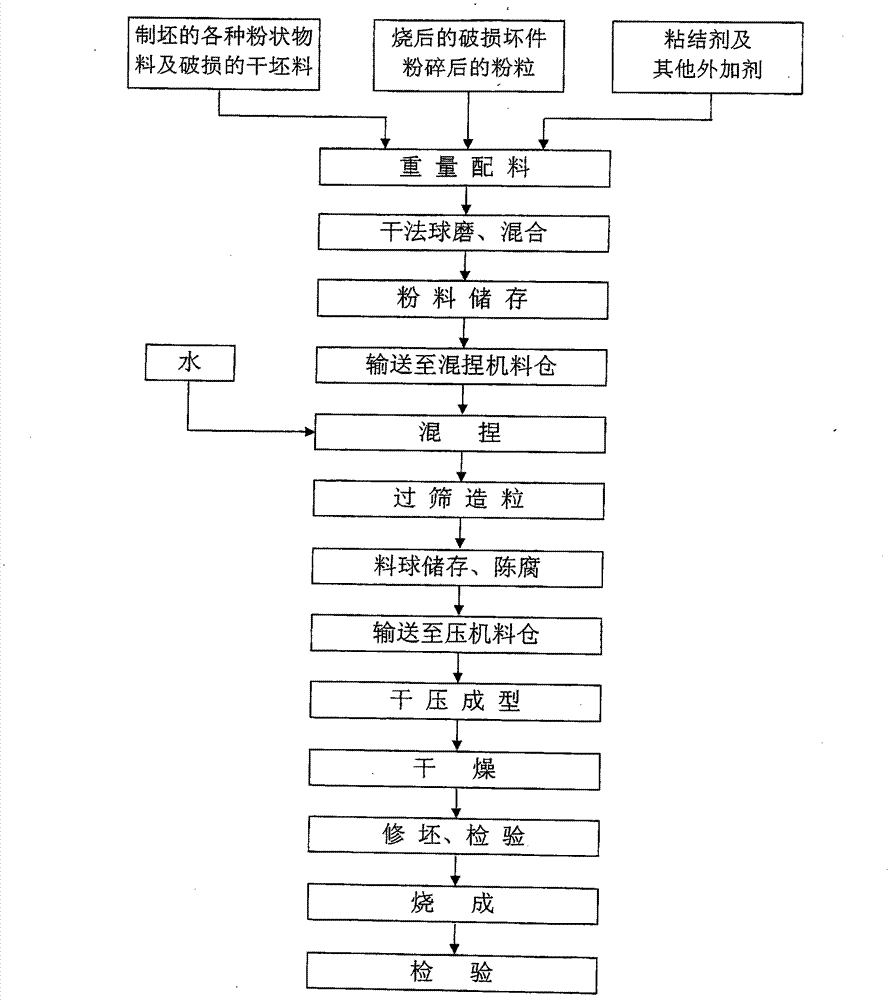

Method used

Image

Examples

Embodiment 1

[0031] Embodiment 1: Prepare raw materials according to the following weight percentage distribution ratio, containing Al 2 o 3 40wt% of gangue-40, cordierite-5, mullite-5, containing Al 2 o 3 15wt% of clay-8, fused quartz 40, lithium feldspar 2, according to the production process, carry out pulverization—mixing—stale—dry powder making—dry pressing molding—firing. After testing, the fired tiles are water-cooled at 1200-25°C for 5 times without cracking. Its coefficient of thermal expansion is 0.92×10 -6

Embodiment 2

[0032] Embodiment 2: prepare raw materials according to the following weight percentage distribution ratio, containing Al 2 o 3 48wt% coal gangue-30, cordierite-10, mullite-15, containing Al 2 o 317wt% of clay-10, fused quartz 30, and lithium feldspar 5, according to the production process, it is pulverized—mixed—stale—dried powder—dry pressing—fired. After testing, the fired tiles are water-cooled for 5 times at 1200°C to 25°C without cracking. Its coefficient of thermal expansion is 1.1×10 -6 .

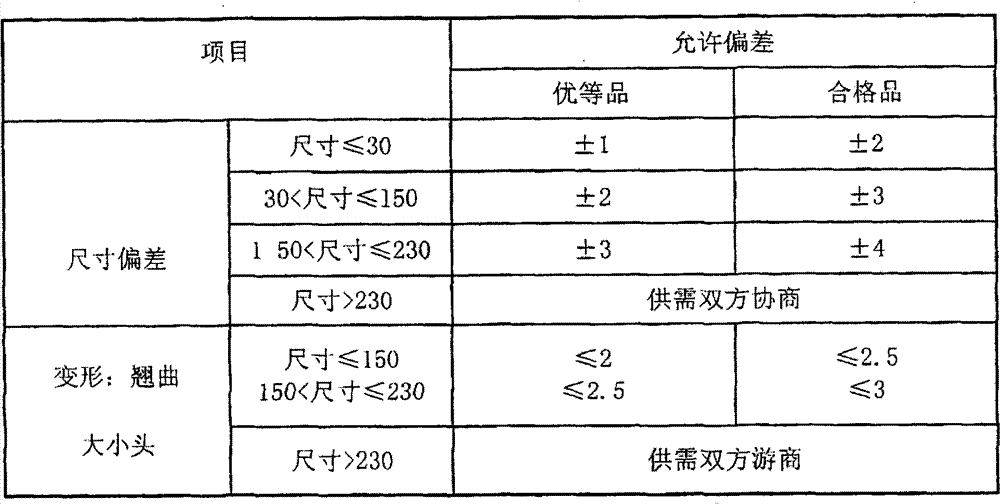

[0033] The dimensional deviation and deformation of the heat-resistant and acid-resistant bricks produced by high-pressure pressing are very small, which fully meet the specific requirements of the national standard JC / T424-2005 "Acid-resistant and heat-resistant bricks". The specific content is shown in the following table:

[0034] Table 3. Acid resistance temperature deviation and deformation

[0035] Unit: mm

[0036]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com