Mixing system suitable for polyurethane production and processing

A mixing system and polyurethane technology, applied in the field of polyurethane production and processing, can solve the problems of low mixing efficiency of raw materials, unable to guarantee the fusion rate of polyurethane raw materials, affecting the quality of polyurethane production and processing, etc., to achieve the effect of improving mixing efficiency and mixing, and ensuring stability. , to ensure the effect of fusion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

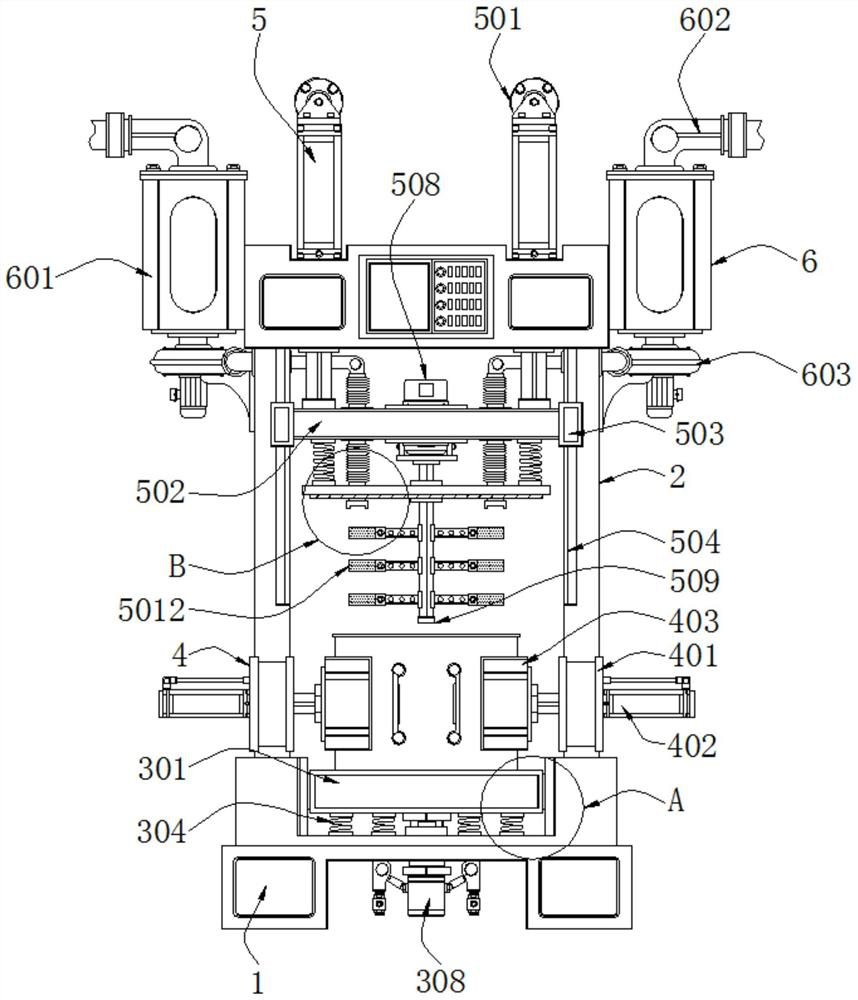

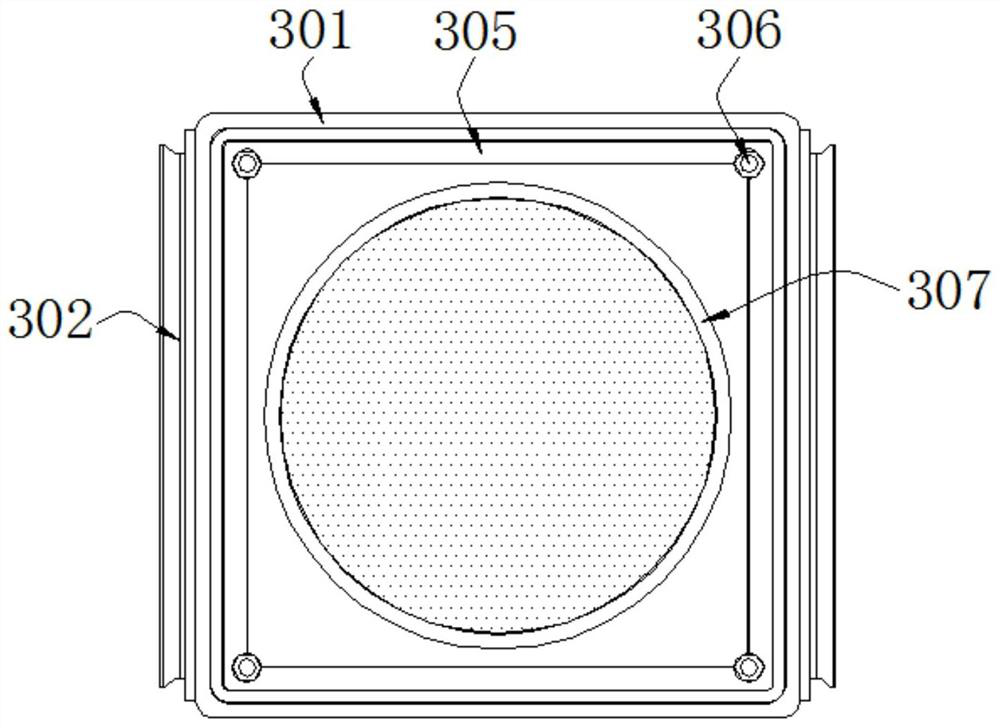

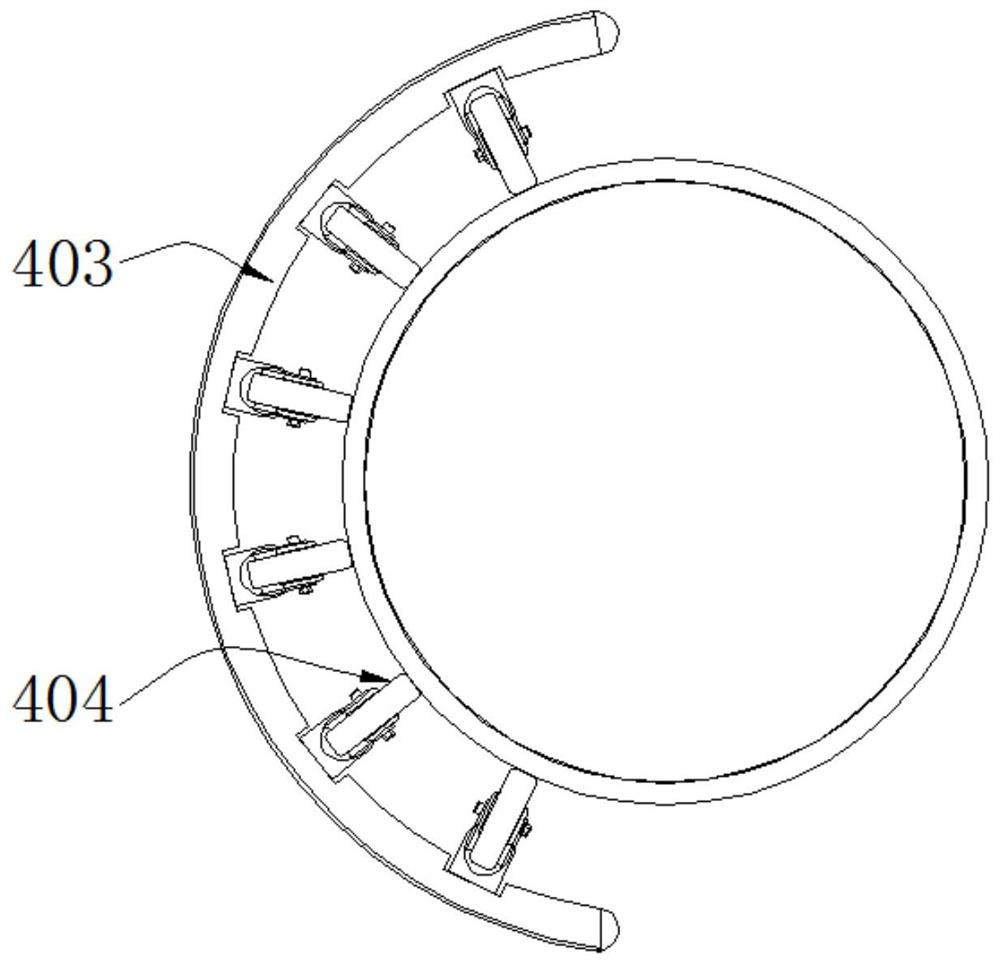

[0029] see Figure 1-7, the present invention provides a technical solution: a mixing system suitable for polyurethane production and processing, including a bearing base 1 and a vibration component 3, the upper end of the bearing base 1 is provided with a fixed frame 2 near the edge, which is used for polyurethane mixing. The vibration component 3 is arranged at the center position of the upper end of the bearing base 1, and the vibration component 3 includes a bearing frame 301, a limit slider 302, a limit groove block 303, a vibration spring 304, a placement groove block 305, a fastening bolt 306, a The slot 307 and the vibration motor 308 are provided with limit sliders 302 on both sides of the outer side of the bearing frame 301, and the outer side of the limit slider 302 is connected with a limit slot block 303, and the lower end of the bearing frame 301 is connected with a vibration spring 304, and A placing slot block 305 is arranged on the inner upper end of the beari...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com