UV reflective paint, and preparation method and application thereof

A technology of reflective paint and reflective agent, applied in the field of paint, can solve problems such as environmental pollution, human harm, irritating odor, etc., and achieve the effect of bright and beautiful appearance, high impact strength, and not easy to age.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

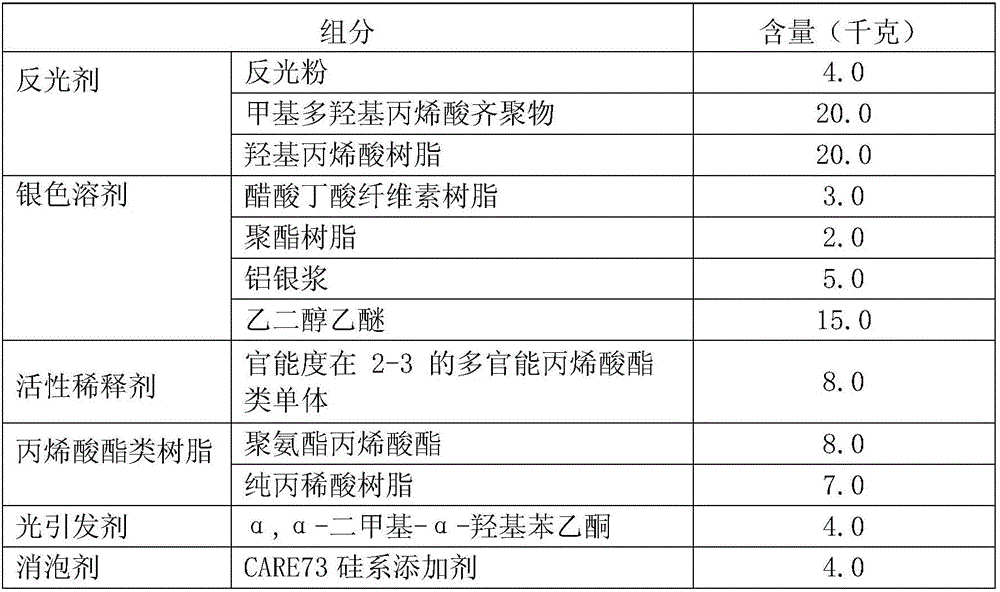

[0022] This UV reflective paint is made of the following components by weight (in terms of 100 kilograms, the same below):

[0023]

[0024] The preparation method of the UV reflective coating adopts the following steps: first, stir and mix the light-reflecting agent, acrylate resin and photoinitiator to obtain a mixture; 35°C, stir in a high-speed disperser at a speed of 800-1000rpm for 20-30 minutes, then add defoamer, stir for 10-15 minutes and keep warm for 1.5-2 hours to disperse the mixture into a stable emulsion to obtain the UV reflective coating.

[0025] Application of the UV reflective coating: Spray the UV reflective coating evenly on the surface of the clean shading cloth substrate with a spray thickness of 10-30 μm, and then irradiate the shading cloth substrate sprayed with the UV reflective coating under a UV lamp with a main peak of 420nm 2-6s on the surface, the UV reflective coating can be cured, and the irradiation energy of the UV lamp is 295mw / cm 2 a...

Embodiment 2

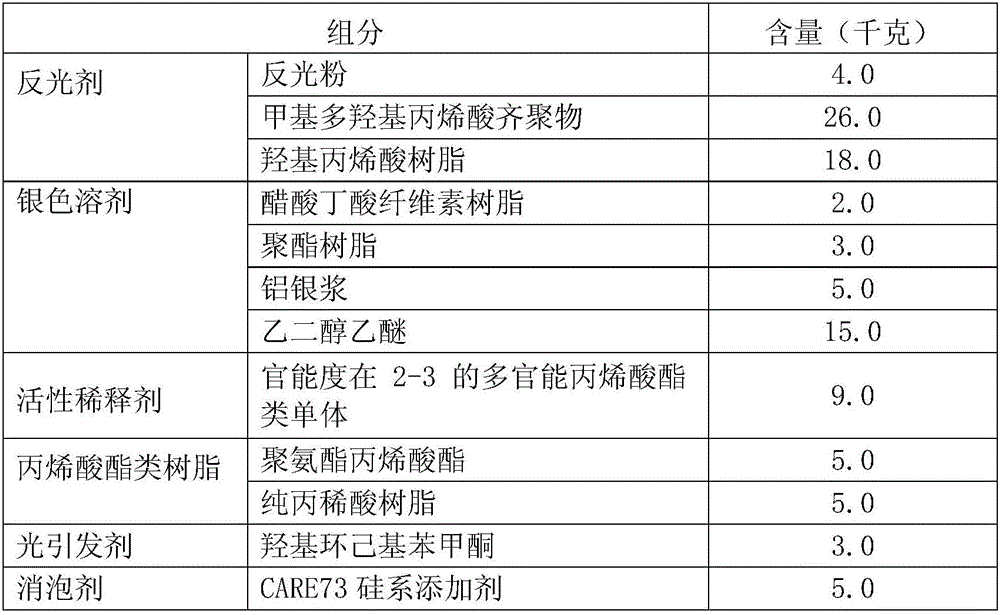

[0027] The UV reflective coating is made of the following components by weight:

[0028]

[0029] The preparation method and application are the same as in Example 1.

Embodiment 3

[0031] The UV reflective coating is made of the following components by weight:

[0032]

[0033]

[0034] The preparation method and application are the same as in Example 1.

[0035] The reflective powder described in Examples 1-3 was purchased from Huizhou Yingguang Plastic Pigment Co., Ltd., the multifunctional acrylate monomer with a functionality of 2-3 was purchased from Shuishan Polymer Company, and the CARE73 silicon-based additive was purchased from Seiko Ink (Hangzhou) Co., Ltd.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Functional group degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com