Method for synthesizing porous cordierite ceramic material by gangue and waste refractory material

A technology of waste refractory materials and porous cordierite, which is applied in the direction of ceramic products, furniture waste recycling, solid waste removal, etc., to achieve the effect of solving pollution and saving production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

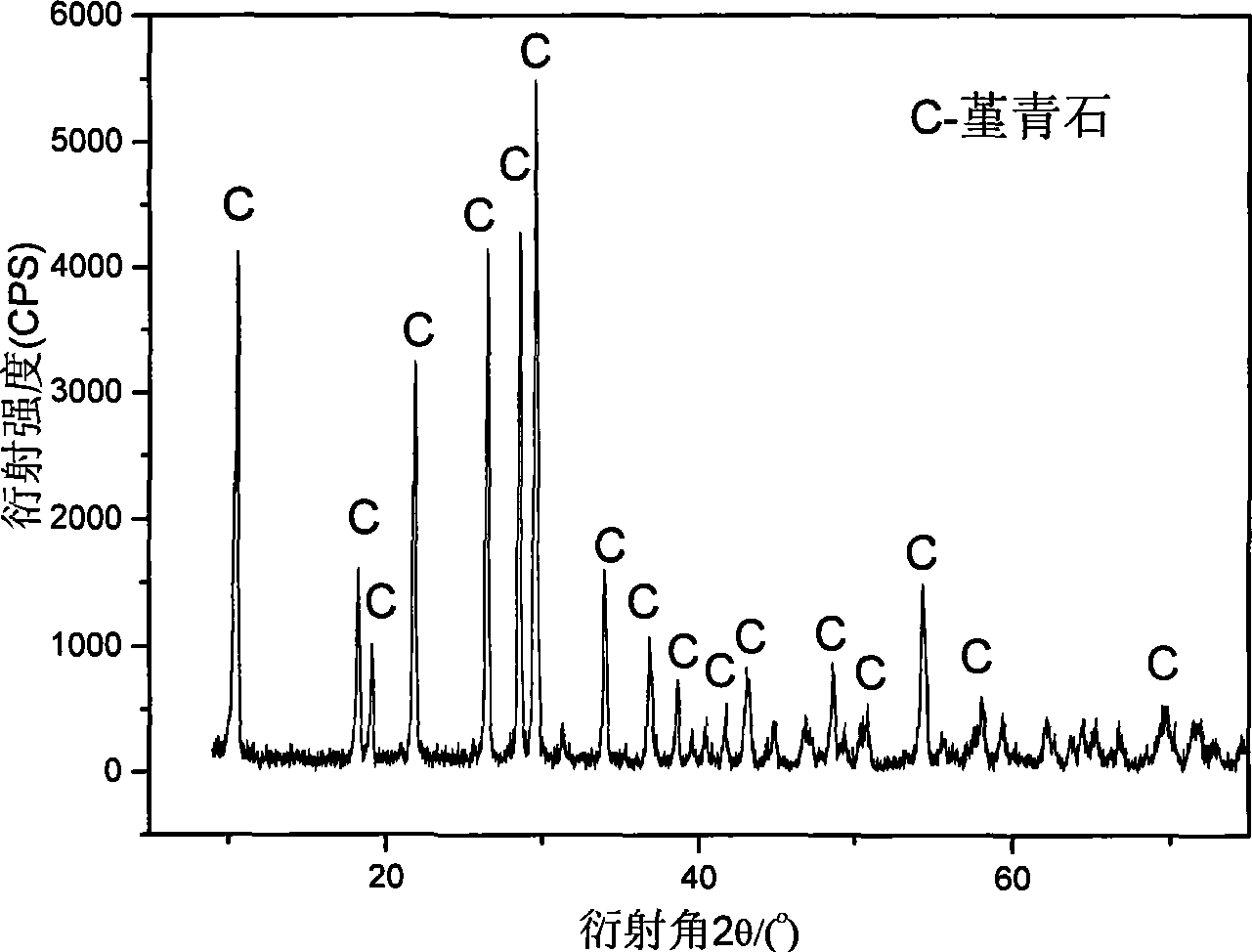

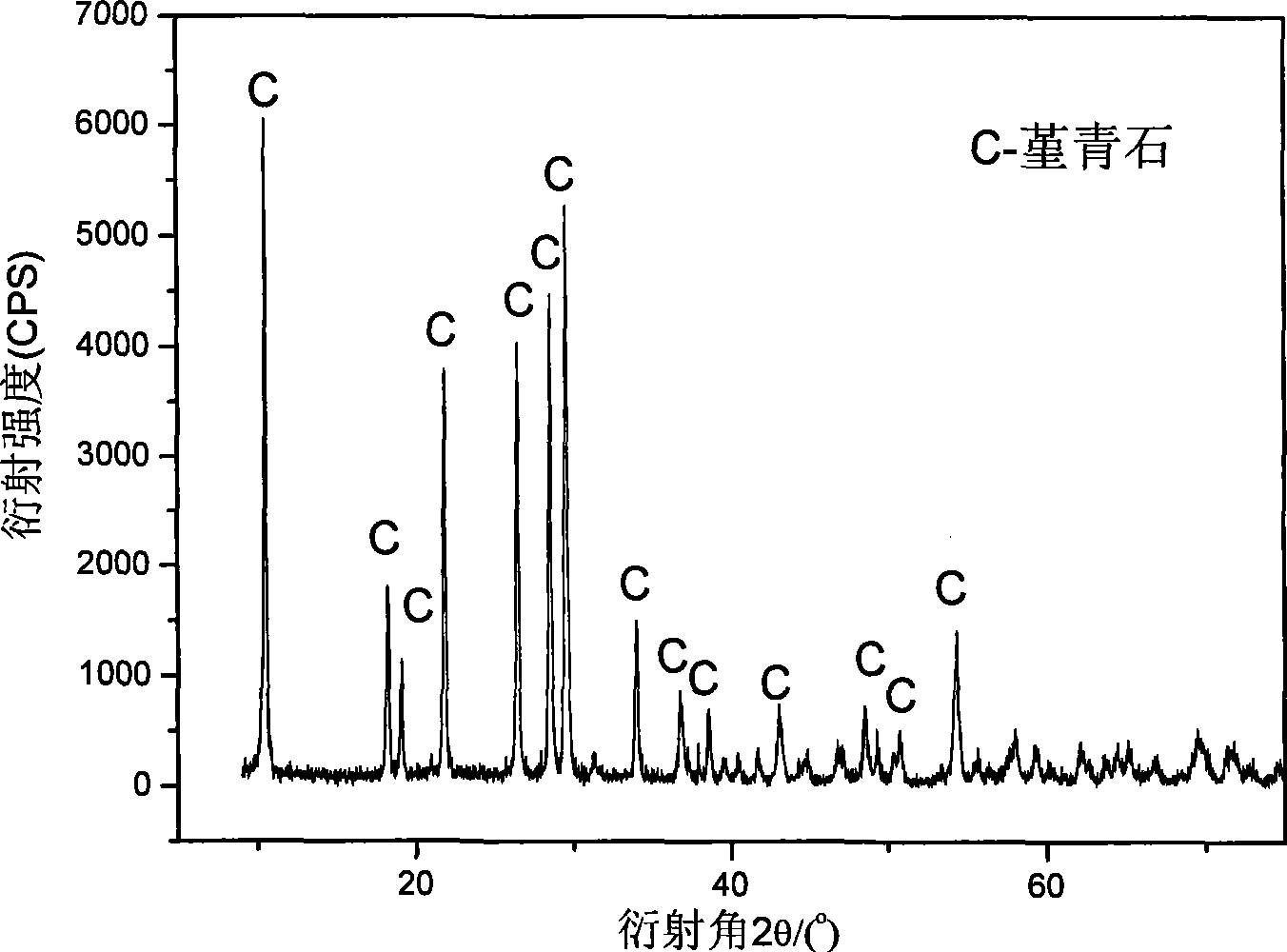

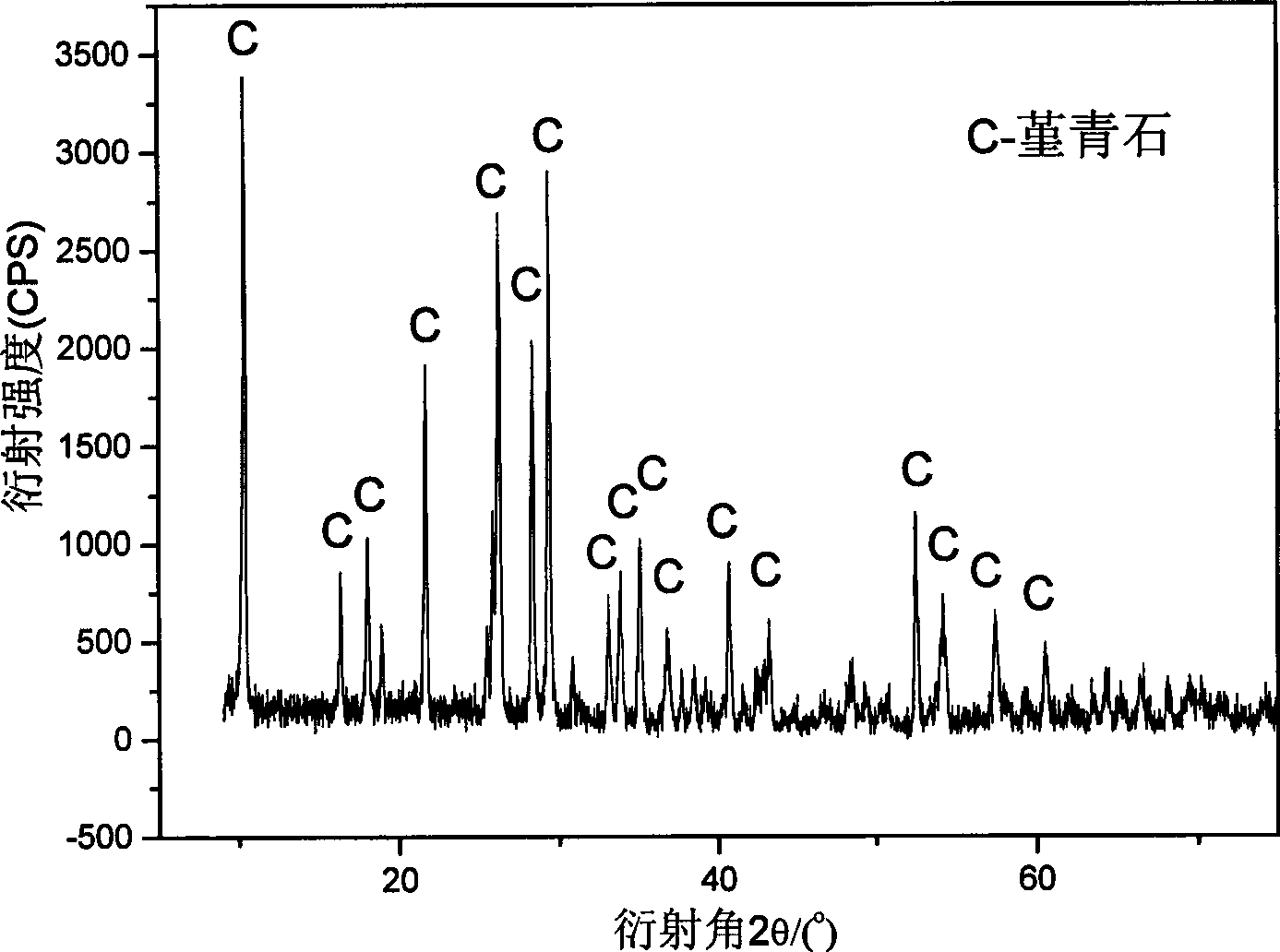

Image

Examples

Embodiment Construction

[0021] (1) Prepare the raw materials according to Table 1, grind them into fine powder, and pass through a 325-mesh sieve.

[0022] (2) Mix the raw materials, use absolute ethanol (mass percentage ≥ 99.7%) or water to dilute, and use agate balls (covered with the bottom of the tank) with a diameter of 1cm as the ball milling medium, put the diluted raw materials and agate balls into the nylon tank After being sealed in the middle, ball mill for 6 hours in a planetary ball mill until the particle size is less than 5um.

[0023] (3) Drying: Put the mixed raw materials into a drying oven at 100°C for 5 hours to dry.

[0024] (4) Molding: add a small amount of polyvinyl alcohol binder (0.5mL / 10g) to the dry raw material, and press it under a pressure of 40MPa.

[0025] (5) High-temperature sintering: sinter the sample body in an air atmosphere at a temperature of 1320° C. to 1420° C. and a holding time of 2-6 hours.

[0026] (6) Cooling: Natural cooling in the air.

[0027] Tab...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com