Building-rubbish resource treatment and use integrated treating method and treating system thereof

A construction waste and treatment method technology, which is applied in the field of construction waste resource disposal and utilization integrated treatment method and its treatment system, can solve the problems of environmental pollution, surface subsidence, land occupation, etc., and achieve the effect of convenient use and efficient utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

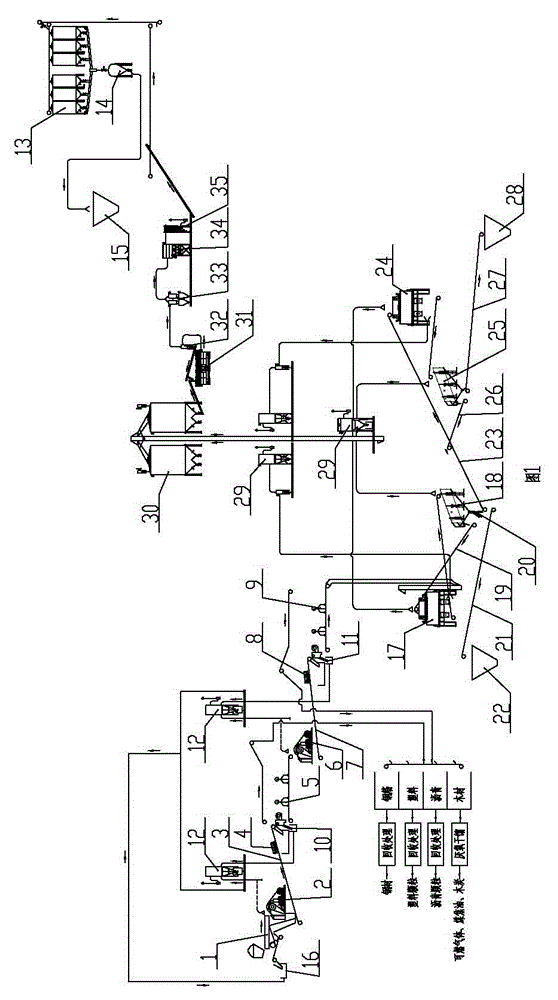

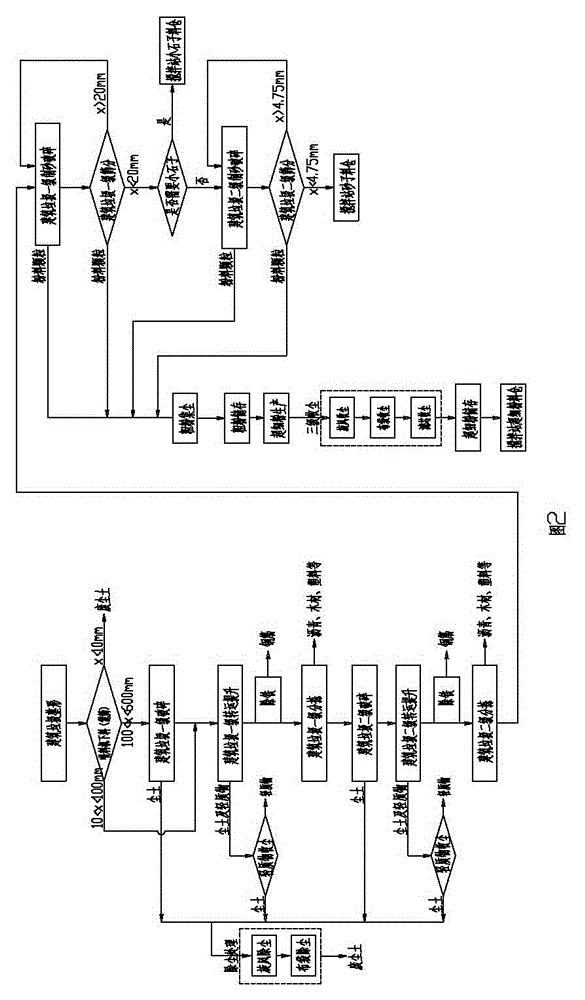

[0042] Embodiment one: as attached figure 1 , 2 As shown, the construction waste resource disposal and utilization integrated processing method includes the following steps:

[0043] Step 1: Reshape the construction waste manually or with a shaping machine, cut and break the steel bars into blocks with a particle size of less than 600 mm;

[0044] Step 2: Sorting the construction waste through the feeding device 1, and then the construction waste with a particle size of less than 600 mm and greater than 100 mm enters step 3, and the construction waste with a particle size of less than 100 mm and greater than 10 mm enters step 4. Construction waste with a particle size of less than ten millimeters enters step 10;

[0045] Step 3: The construction waste is subjected to primary crushing through the primary crushing device 2, and then the construction waste enters step 4, and the dust particles generated by the primary crushing enter step 9; The steel bars are separate...

Embodiment 2

[0064] Embodiment two: as attached figure 1 , 2 As shown, the processing system of the integrated ecological concrete factory includes a sorting and processing device capable of separating soil, steel, plastic, asphalt and wood from construction waste, and a crushing device capable of crushing construction waste into small stones, sand and powder Processing device, the discharge port of the sorting processing device communicates with the feed port of the crushing processing device. The sorting processing device includes a dust removal device 12 that can collect dust particles and use them as waste dust. The crushing processing device includes dust particles that can be collected and used as concrete. Dust collection device for processing raw materials. The soil, steel, plastic, asphalt and wood in the construction waste can be separated through the sorting and processing device. The soil can be used as cushion soil, gardening soil or processed into clay bricks. Scrap iron...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com