Harmless gasification treating process for medical waste

A technology of medical waste and treatment process, which is applied in the direction of solid waste removal, incinerator, petroleum industry, etc., can solve the problems of non-development direction, waste of resources, high treatment cost, etc., and achieve saving of transportation and treatment costs, obvious social benefits and The effect of the environmental effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

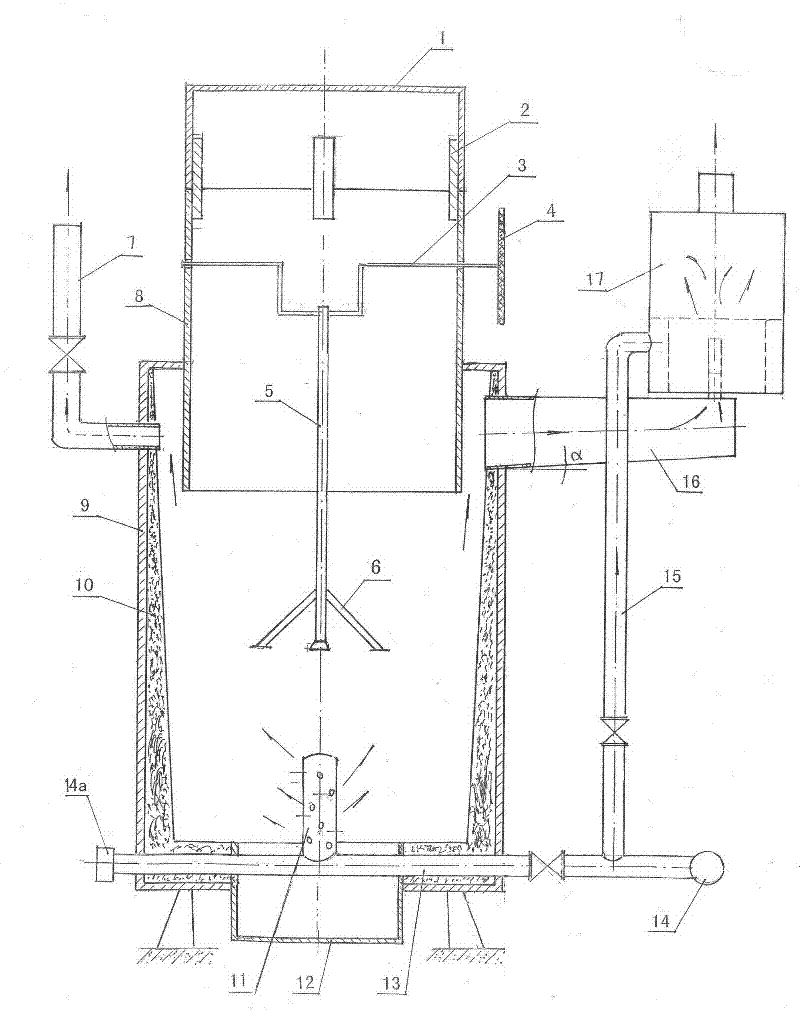

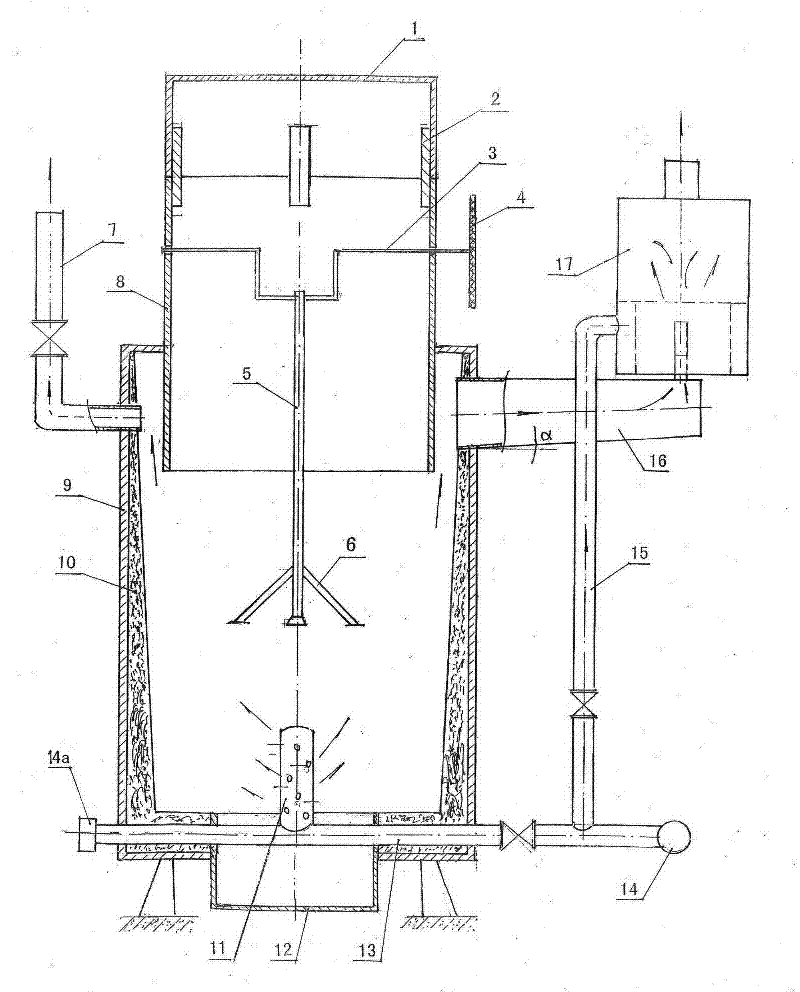

[0015] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0016] Such as figure 1 As shown, a gasification furnace for medical waste treatment used in the present invention can also be called a batch gasification furnace, which includes a top cover 1, a positioning plate 2, a protruding shaft 3, a balance wheel 4, a pressing rod 5, Press plate 6, smoke exhaust pipe 7, feed bin 8, furnace body 9, refractory inner layer 10, air nozzle 11, lower hopper 12, primary air supply pipe 13, fan 14, secondary air supply pipe 15, net gas delivery pipe 16 and gas burning tower 17, wherein manual valve is housed on exhaust pipe 7, primary air supply pipe 13 and secondary air supply pipe 15, blower fan 14 selects 3~30w miniature fan for use, air nozzle 11 selects the air nozzle of high temperature resistance for use, In the prior art, the binder rod 5 and the pressing plate 6 are preferably ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com