Method for preparing silver/silver chloride composite nanocube

A nano-cube, silver chloride technology, applied in the direction of chemical instruments and methods, nanotechnology, nanotechnology, etc., can solve the problems of in-depth understanding of the limited catalytic activity performance, poor uniformity of silver chloride materials, poor stability, etc., to achieve excellent The effect of good activity, uniformity and high product yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] 1. Preparation of silver chloride nanocubes

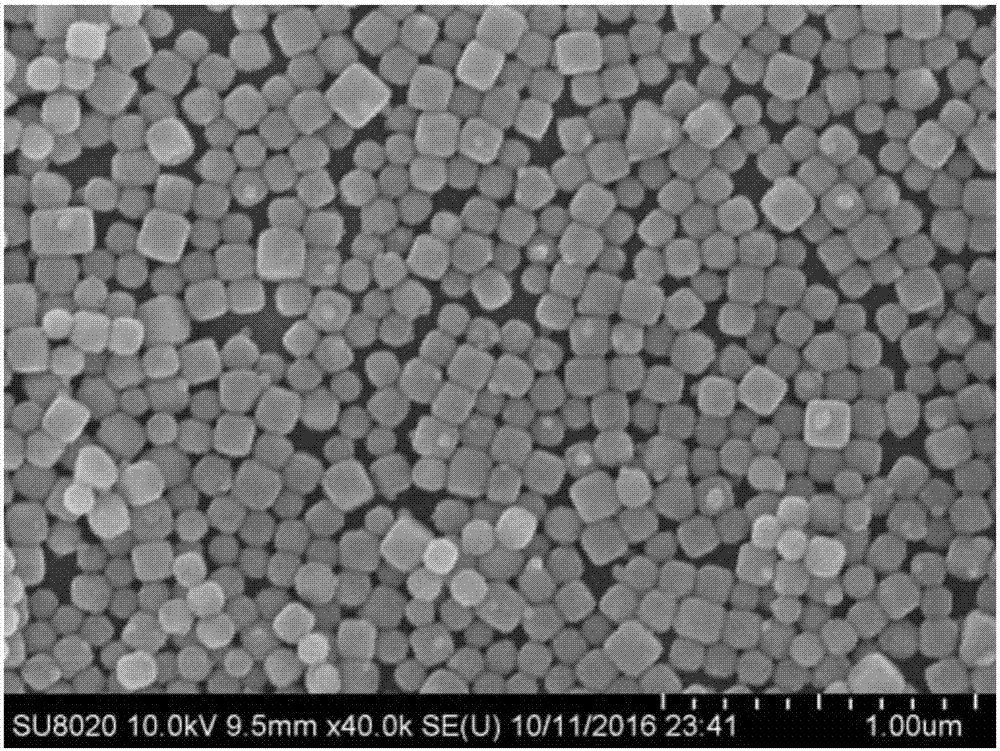

[0031] Take 0.5mL of 0.1mol / L silver nitrate aqueous solution, 1mL of 0.5mol / L polyallylamine hydrochloride aqueous solution with a number average molecular weight of 150000, and 20mL of 0.025mol / L sodium chloride aqueous solution, and mix them evenly with 0.5mol / L hydrogen Sodium oxide aqueous solution adjusts the pH value of the resulting mixed solution to 8, reacts for 1.5 hours at 60° C., and centrifuges to obtain silver chloride nanocubes (see figure 1 ).

[0032] 2. Preparation of silver / silver chloride nanocubes

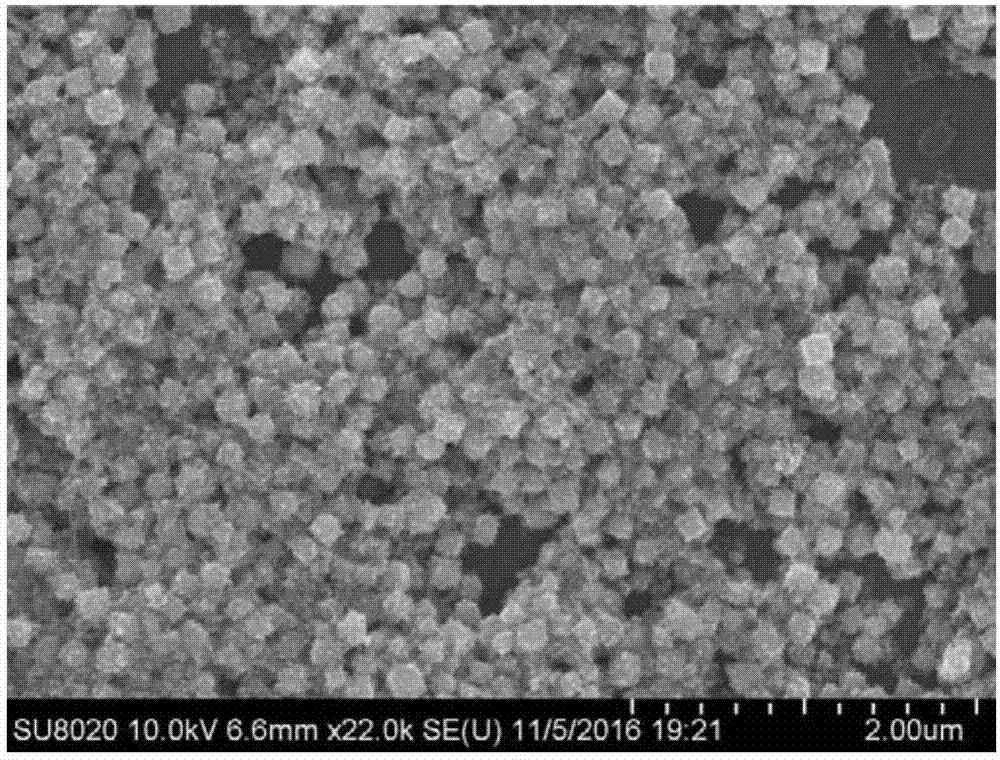

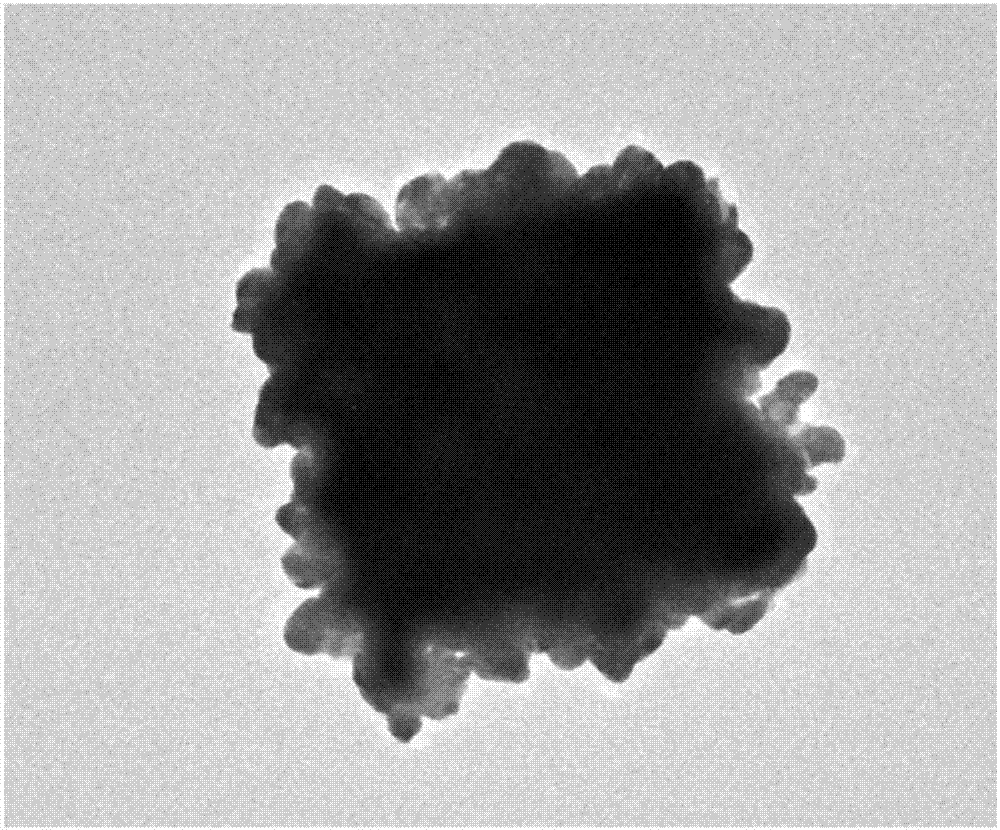

[0033] Add the silver chloride nanocubes obtained in step 1 into 10 mL of diethylene glycol, disperse them uniformly by ultrasonic, and reduce them at 150° C. for 1.5 hours to obtain silver / silver chloride nanocubes. Depend on figure 2 with 3 It can be seen that the size of silver / silver chloride nanocubes is about 120-130 nm.

Embodiment 2

[0035] In embodiment 1, the sodium chloride aqueous solution of 20mL 0.025mol / L is replaced with the potassium chloride aqueous solution of 20mL 0.025mol / L, and other steps are identical with embodiment 1, obtain silver / silver chloride nanocube (see Figure 4 ).

Embodiment 3

[0037] In Example 1, 1 mL of 0.5 mol / L polyallylamine hydrochloride aqueous solution with a number average molecular weight of 150,000 was replaced with 1 mL of 0.5 mol / L polyallylamine hydrochloride aqueous solution with a number average molecular weight of 5000. Other steps and examples 1 is the same to obtain silver / silver chloride nanocubes (see Figure 5 ).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com