Method for applying metal features onto metallized layers using electrochemical deposition using acid treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

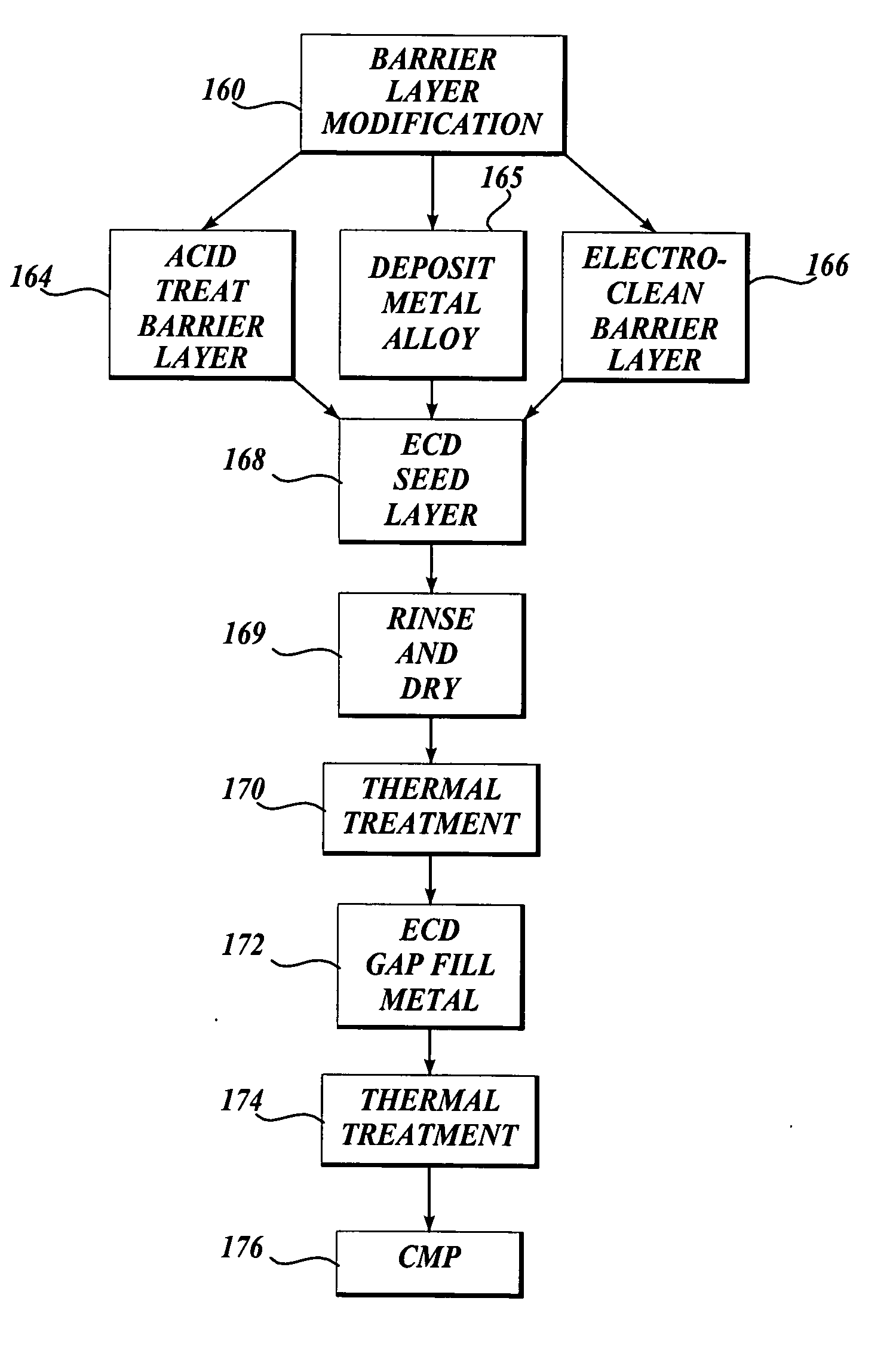

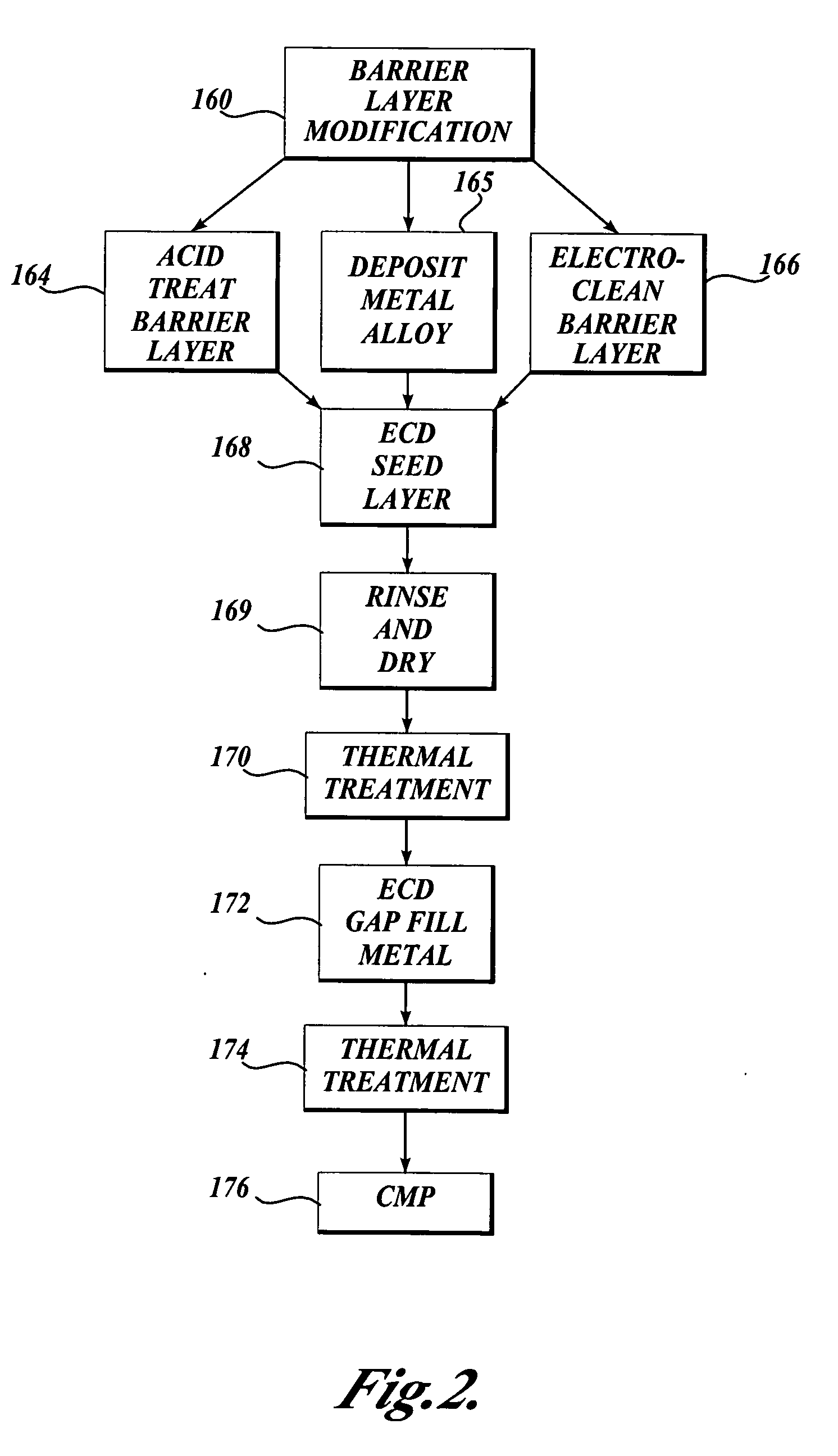

Method used

Image

Examples

example 1

Acid Treatment of Barrier Layer

[0096] Acid treatment of a tantalum barrier was performed using 2% by weight aqueous solution of hydrofluoric acid. A 200 mm blanket wafer deposited with 25 nanometers of PVD tantalum barrier was used. This rotating wafer was subjected to a water spray treatment for 15 seconds followed by an acid spray treatment for 15 seconds. Then the rotating wafer was cleaned by spraying de-ionized water for another 15 seconds to remove the excess acid from its surface. For an additional 5 seconds, the wafer was rotated to sling off large water droplets. The wafer was then wet-transferred to a plating chamber. In the plating chamber, the wafer was plated with copper up to a thickness of ˜80 nanometers. After plating, the wafer was cleaned insitu with de-ionized water and the wafer was transferred to a SRD (Spin, Rinse, and Dry) chamber. In this SRD chamber, the spinning wafer was once again cleaned with de-ionized water thoroughly to remove any plating chemistry l...

example 2

Electrolytic Treatment of Barrier Layer

[0097] Electrolytic treatment of a tantalum barrier was performed using 2% by weight of potassium hydroxide aqueous solution. A 200 mm blanket wafer with 25 nanometers of PVD tantalum barrier was treated. This rotating wafer was used as a cathode and subjected to a current of 1 A (˜3 mA / cm2) for one minute while an inert platinum electrode was the anode. The wafer was then wet-transferred to a SRD chamber where the spinning wafer was rinsed with de-ionized water and then once again wet transferred to a plating chamber. In the plating chamber, the wafer was plated with copper up to a thickness of about 80 nanometers. After plating, the wafer was cleaned insitu with de-ionized water and the wafer was transferred to a SRD chamber. In this SRD chamber, the spinning wafer was once again cleaned with de-ionized water thoroughly to remove any plating chemistry left on its surface. After rinsing, the wafer was dried by spinning it in the chamber for s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Current density | aaaaa | aaaaa |

| Power | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com