Method for preparing magnesium deuteride by adopting high-temperature direct process

A magnesium deuterium, direct method technology, applied in the intersection of material science and nuclear technology, can solve the problems of high cost, high activity, and high equipment requirements, and achieve the effects of high product yield, simple operation process and good purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

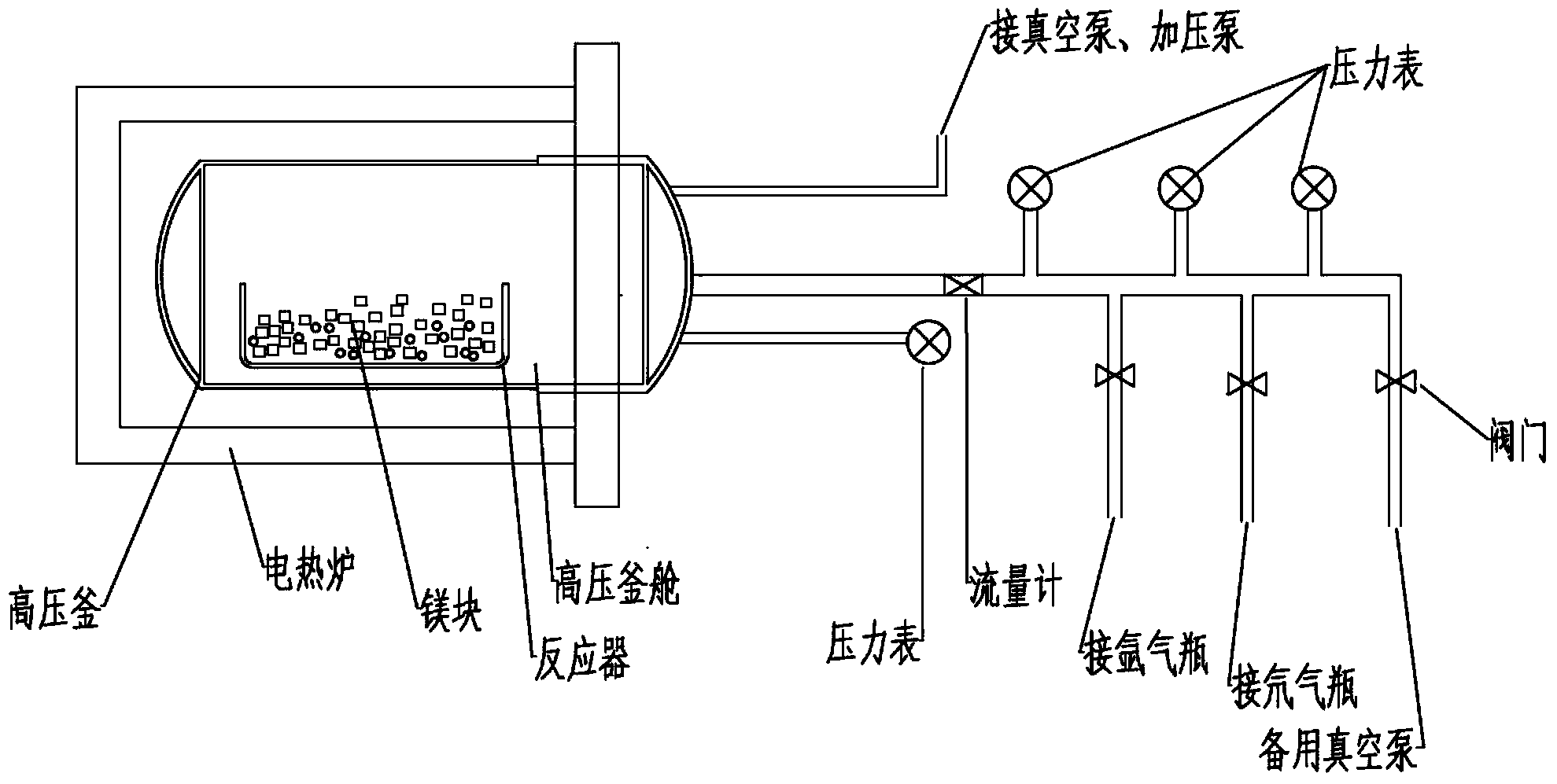

[0023] Under argon protection, take by weighing 603g of magnesium nuggets with a particle size of 8mm and a purity of 99.99%, put them into a high-temperature and high-pressure reactor, and place the reactor in a high-pressure reactor cabin, such as figure 1 As shown: Use argon to replace the gas in the kettle cabin, pump the pressure in the cabin to a negative pressure of 0.023MPa, introduce 99.999% high-purity deuterium gas, and pump it again to a negative pressure of 0.018MPa, repeat the operation twice; at 10°C Rapidly raise the temperature to 266°C / min, feed high-purity deuterium gas, increase the pressure of deuterium gas in the kettle cabin to 100 atmospheres, and react for 50 minutes; heat up at a speed of 10°C / min for 38 minutes to 422°C to stop heating, keep the temperature constant and The deuterium gas flow rate continues to react for 70 minutes until the pressure of the deuterium gas pressure gauge and the autoclave are completely balanced; at this time, the temper...

Embodiment 2

[0025] Under an argon atmosphere, the magnesium block with a purity of 99.99% is cut into small pieces with a particle size of 10 mm, weighed 2512 g, and put it into a high-temperature and high-pressure reactor, and the reactor is placed in a high-pressure reactor cabin; Replace the gas in the tank with gas, pump the pressure in the cabin to a negative pressure of 0.019MPa, introduce 99.999% high-purity deuterium gas, and pump it again to a negative pressure of 0.015MPa, and repeat the operation 4 times; at a heating rate of 20°C / min Rapidly raise the temperature to 296°C, feed high-purity deuterium gas, and increase the pressure of deuterium gas in the tank to 150 atmospheres; after 72 minutes of reaction, simultaneously raise the temperature at a rate of 12°C / min for 34 minutes to 533°C to stop heating, keep the temperature constant and The deuterium gas flow rate continued to react for 85 minutes until the pressure of the deuterium pressure gauge and the autoclave were compl...

Embodiment 3

[0027] Under the protection of argon, use fine sandpaper to polish the oxide layer on the surface of the magnesium block with a purity of 99.99% to a metallic luster, cut it into small pieces with a particle size of 14mm, weigh 408g, and put it into a high-temperature and high-pressure reactor. The device is placed in the high-pressure reactor cabin, such as figure 1 As shown: Replace the gas in the kettle cabin with argon, pump the pressure in the cabin to a negative pressure of 0.020MPa, introduce 99.999% high-purity deuterium gas, and pump it again to a negative pressure of 0.015MPa, repeat the operation 3 times; / min to quickly raise the temperature to 245°C, introduce high-purity deuterium gas, and increase the pressure of deuterium gas in the tank to 200 atmospheres; control the flow rate to 2041ml / min, and at the same time raise the temperature at a speed of 8°C / min for 55min to 537 Stop heating at ℃, keep the temperature and deuterium flow rate constant, and continue t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com