Reactive compensation structure for metallurgical submerged-arc furnace

A compensation structure, the technology of submerged arc furnace, applied in the direction of reactive power compensation, reactive power adjustment/elimination/compensation, harmonic reduction devices, etc., can solve the problems of only a large number of low-voltage capacitors, low voltage, and inability to meet compensation requirements , to achieve the effect of stable operation, reducing energy consumption and increasing product output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

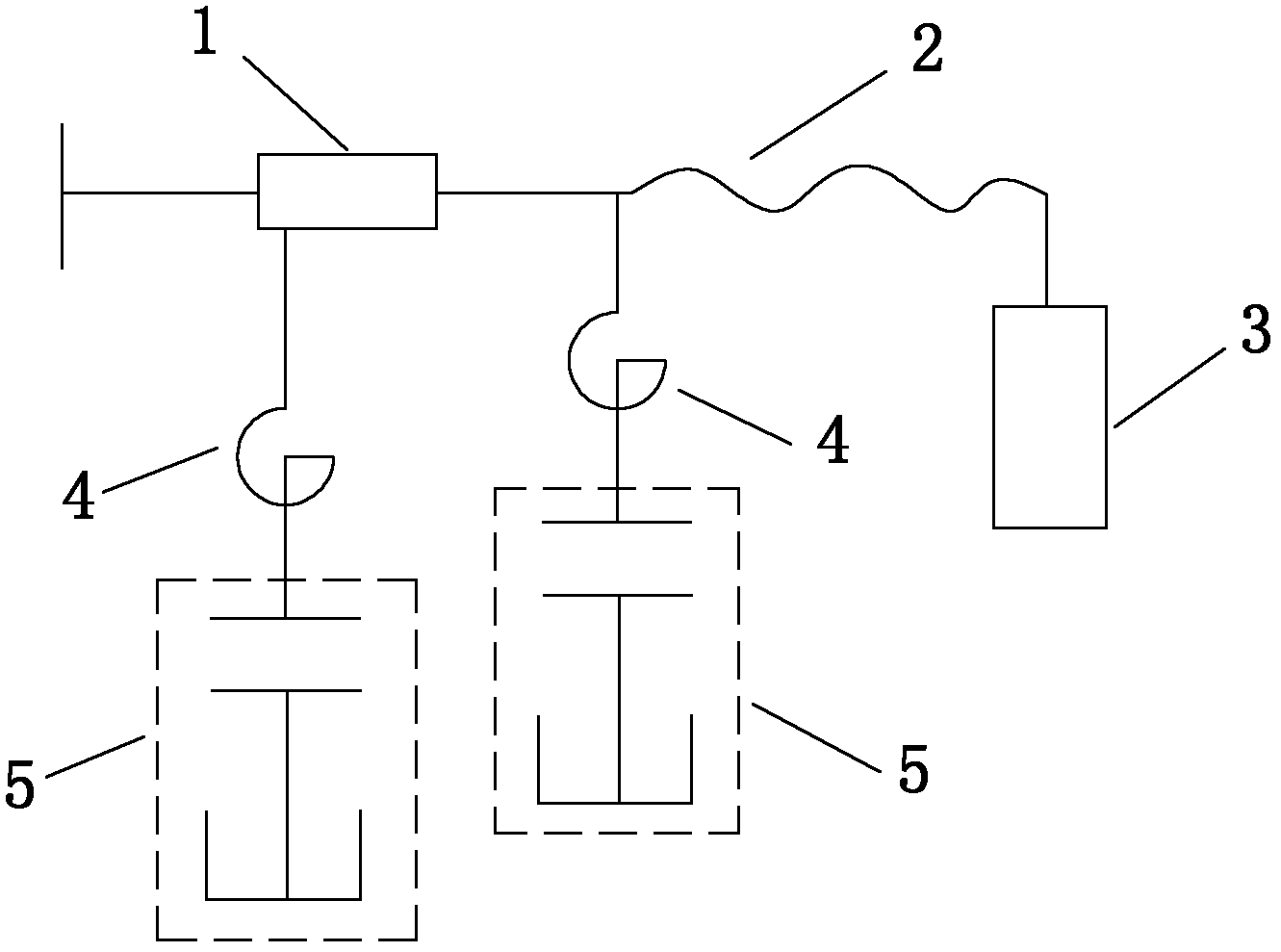

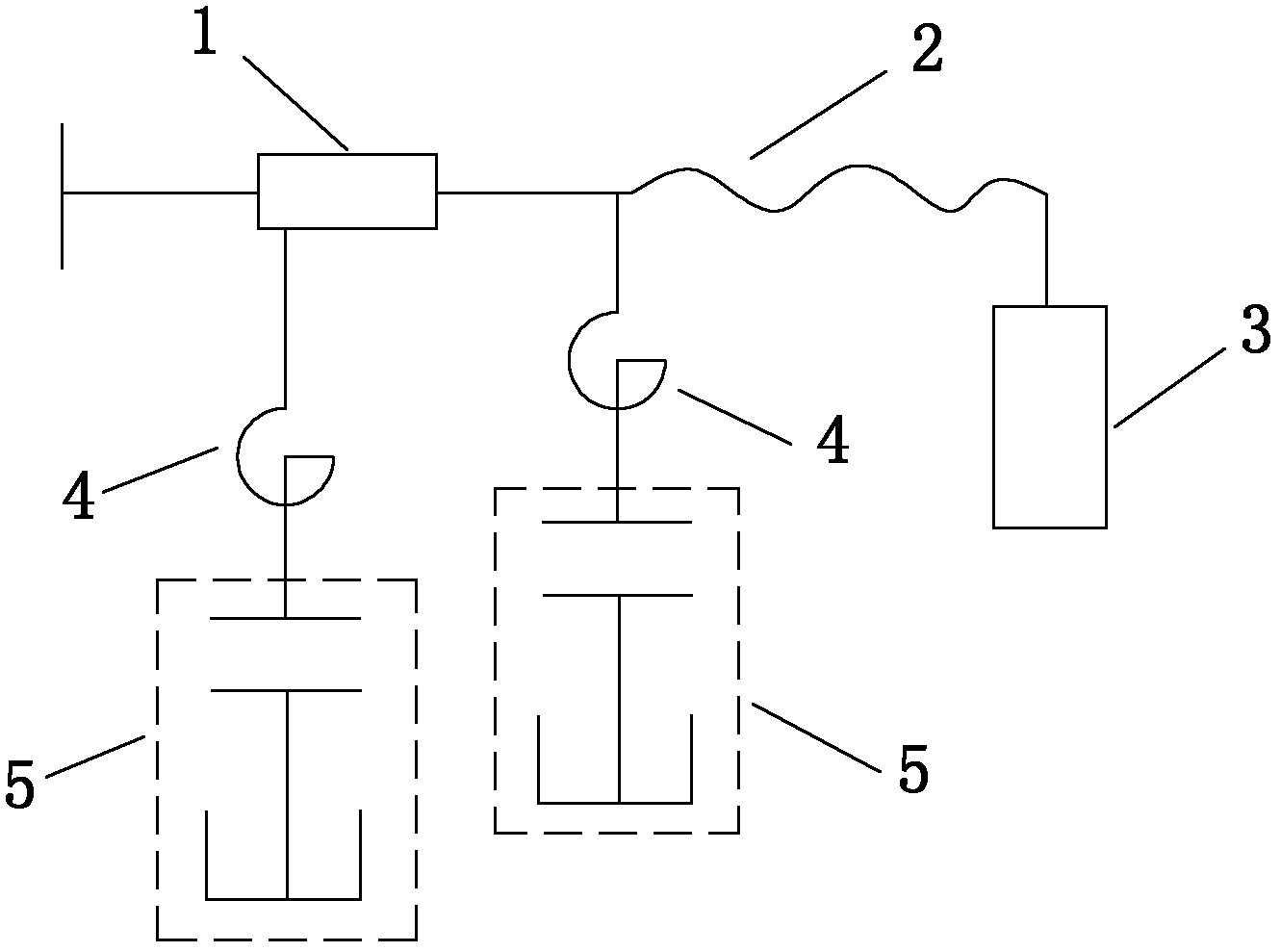

[0013] like figure 1 The reactive power compensation structure of the metallurgical submerged arc furnace shown in the present invention includes an electric furnace transformer 1 connected to the input current, the downstream of the electric furnace transformer 1 is connected to the electric furnace body 3 through the short network 2, and the medium voltage side of the electric furnace transformer 1 is connected in parallel with the main line The medium-voltage compensation unit is connected in parallel with the low-voltage compensation unit at the front end of the short network 2. Both the medium-voltage compensation unit and the low-voltage compensation unit include a resonant circuit in which a filter reactor 4 and a capacitor 5 are connected in series, and the capacitance in the capacitor 5 is connected in a star-shaped manner. The voltage value of the filter reactor 4 in the medium voltage compensation unit is 10KV, and the withstand voltage value of the capacitor in the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pressure value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com