Method for preparing nano molecular sieve microspherical catalyst

A nano-molecular sieve and catalyst technology, which is applied in the direction of molecular sieve catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the adverse catalytic performance of SAPO-34 molecular sieve, the influence of SAPO-34 molecular sieve utilization rate, and the performance of SAPO-34 molecular sieve Differences and other issues can be achieved to solve the size control problem, reduce the risk of damage, and improve the uniformity of growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Nano molecular sieve preparation

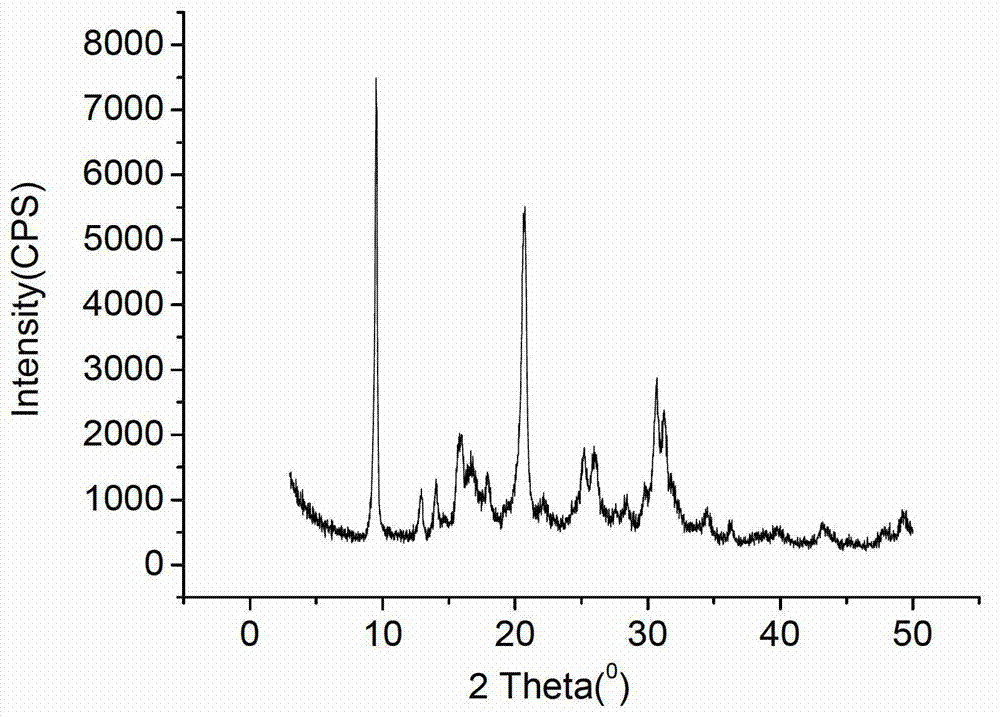

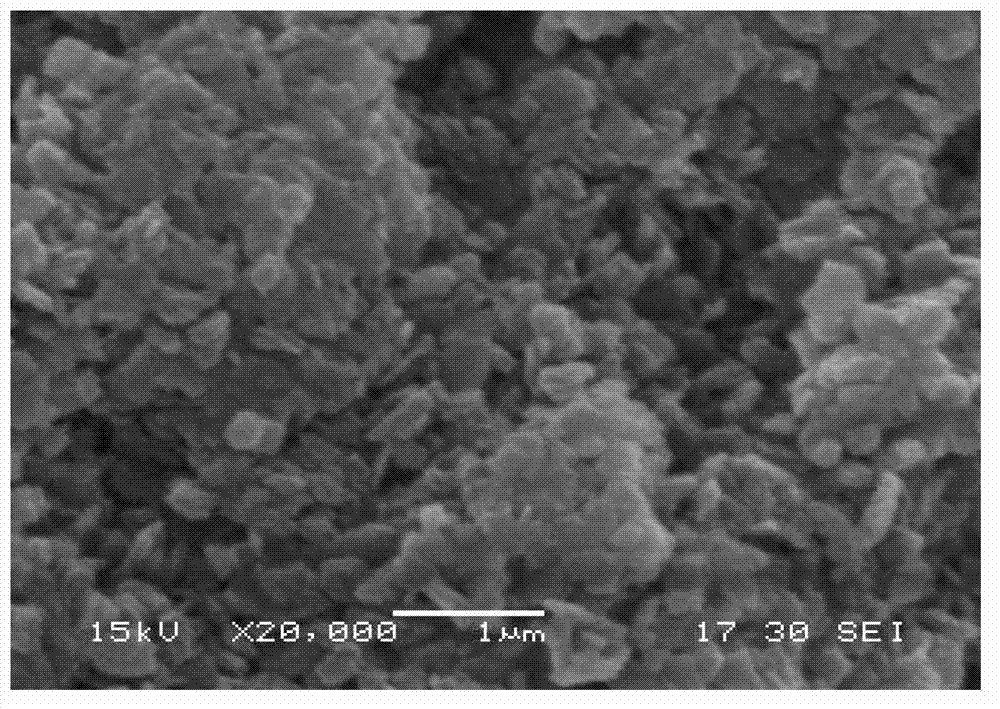

[0041] 7.8g pseudo-boehmite (content 65%) was mixed with 110g tetraethylammonium hydroxide and stirred for 30 minutes, after stirring evenly, 3.6g silica sol (content 25%) was added thereto, then slowly added 11.5g phosphoric acid (content 85%), stirred at room temperature for 12 hours, under dynamic conditions, nucleated at 100-160°C for 2-4h, cooled naturally, added 260g deionized water, crystallized by microwave at 150-180°C for 40-80min, and the product was washed , dried at 110°C for 12 hours, and roasted at 600°C for 4 hours. XRD test showed that the molecular sieve was SAPO-34 molecular sieve ( figure 1 ), SEM test shows that gained molecular sieve is nano molecular sieve ( figure 2 ).

Embodiment 2

[0043] In situ synthesis of nanomolecular sieves

[0044] (1) Preparation of kaolin microspheres

[0045] First kaolin 3000g, silica sol 1000g (solid content 25%) and certain P 2 o 5 / Al 2 o 3 200g of phosphorus-aluminum sol in molar ratio and 1560g of deionized water were mixed to form a uniform slurry, and then 30g of polyethylene glycol was added through a rubber mill for rubber grinding, so that the particle size was less than 3 μm, and 90% of the particle size was less than 2 μm. 70% of the particle size is less than 1 μm; then the mixed slurry is spray-dried to obtain kaolin microspheres, the particle size is between 20-150 μm, the average particle size is 60 μm, and roasted at 950 ° C for 1-4 hours to obtain kaolin microspheres .

[0046] (2) Preparation of nano-molecular sieve microsphere catalyst

[0047] 7.8g pseudo-boehmite (content 65%) was mixed with 110g tetraethylammonium hydroxide and stirred for 30 minutes, after stirring evenly, 3.6g silica sol (content...

Embodiment 3

[0049] In situ synthesis of nanomolecular sieves

[0050] (1) Preparation of montmorillonite microspheres

[0051] First, the montmorillonite is rubber-milled by a rubber mill so that the particle size is less than 2 μm, wherein 90% of the particle size is less than 2 μm, and 70% of the particle size is less than 1 μm; then get 3000 g of gained kaolin and 1200 g of aluminum sol Content 25%) and deionized water 1560g are mixed into a uniform slurry, and the kaolin microspheres are prepared by spray drying method, the particle size is between 20-150 μm, the average particle size is 80 μm, and roasted at 1000 ° C for 1-4h to obtain Monto soil microspheres.

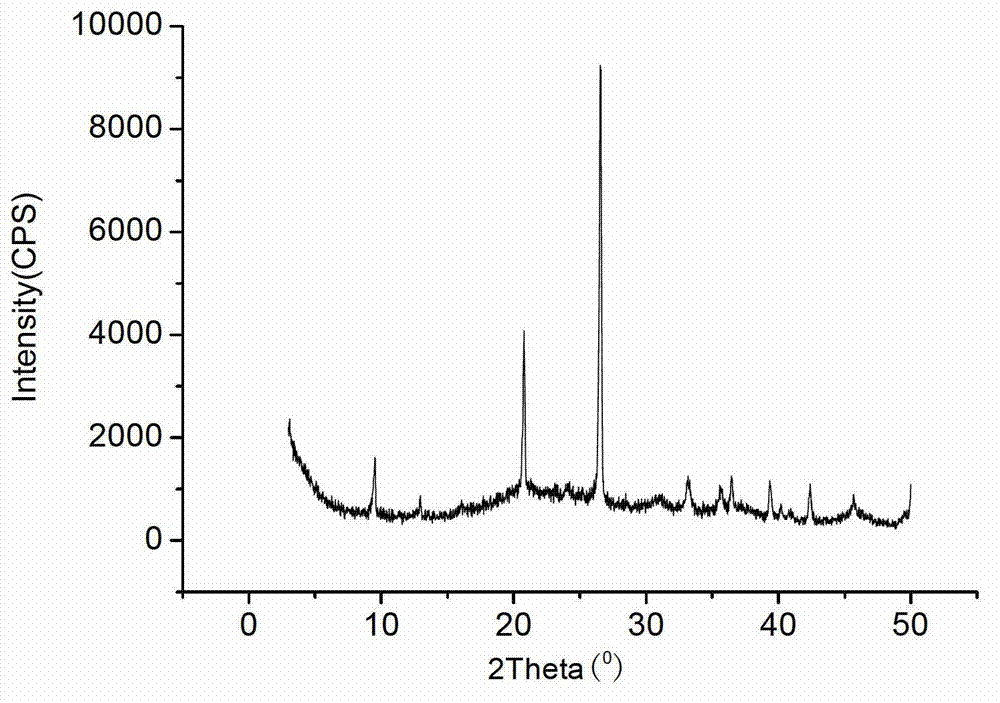

[0052] (2) Preparation of nano-molecular sieve microsphere catalyst

[0053] 7.8g pseudo-boehmite (content 65%) was mixed with 110g tetraethylammonium hydroxide and stirred for 30 minutes, after stirring evenly, 3.6g silica sol (content 25%) was added thereto, then slowly added 11.5g phosphoric acid (content 85%), after st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com