Method for promoting crystal growth of casting blank in crystallizer and crystallizer thereof

A technology to promote crystallization and crystal growth, which is applied in the field of molds for continuous steel casting, can solve problems affecting the casting speed of continuous casting machines, rhombic change, and the uniformity of crystal growth of the slab shell, so as to improve the crystal growth of the slab shell Uniformity, increase casting speed, and avoid shell shell cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

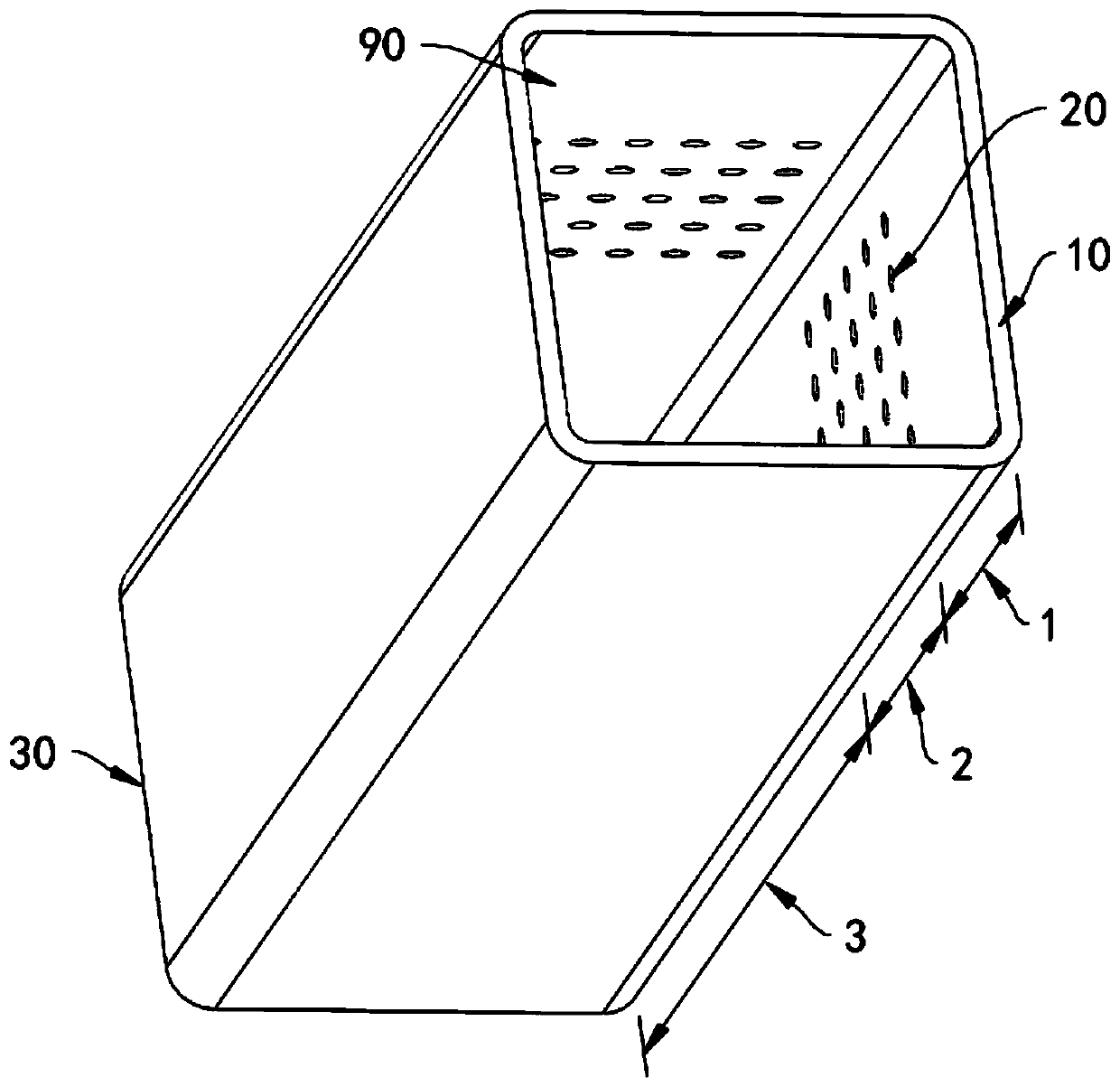

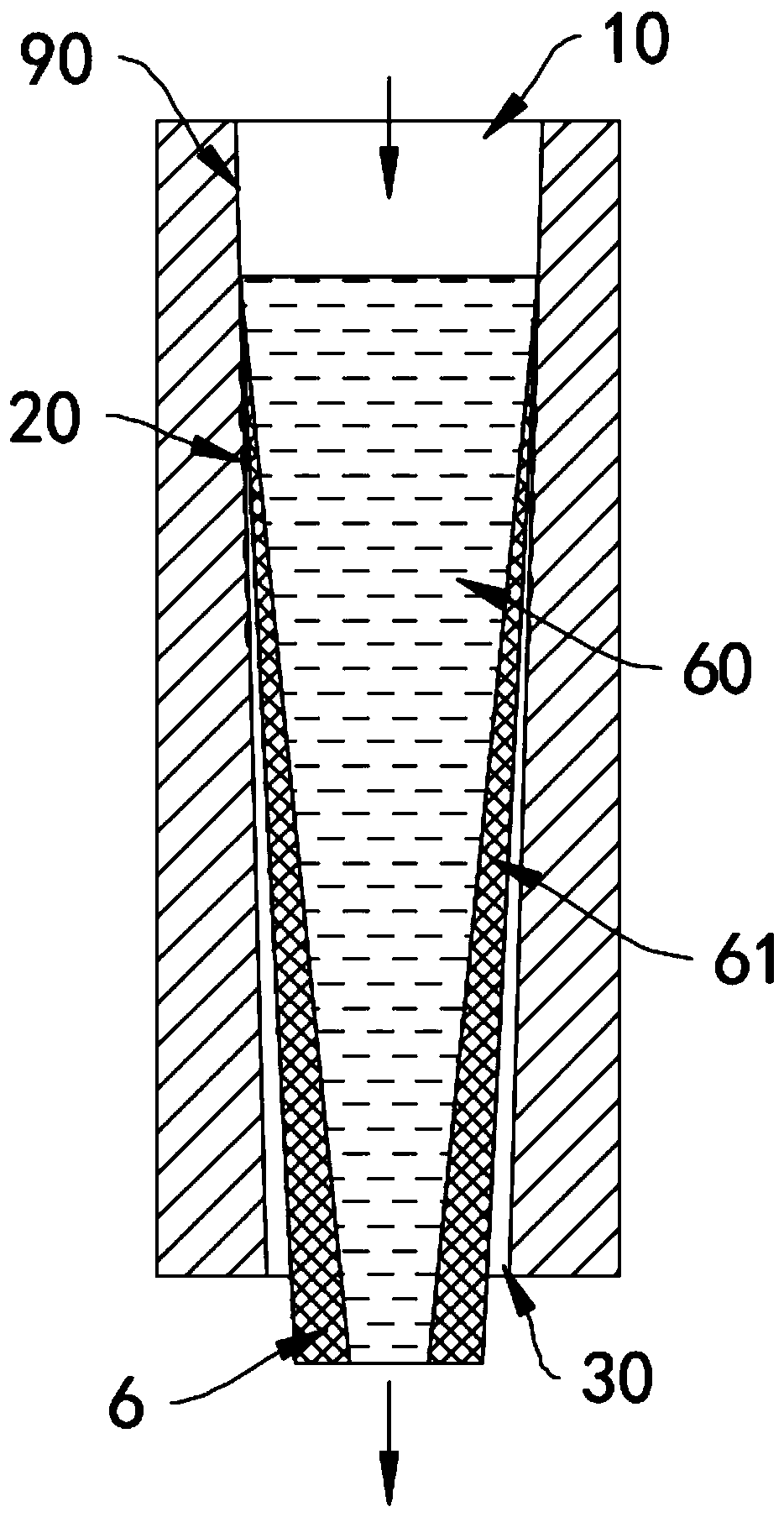

[0043] Such as figure 1 As shown, an array type crystallizer comprises a crystallizer upper port 10 and a crystallizer lower port 30, and the crystallizer inner wall 90 between the crystallizer upper port 10 and the crystallizer lower port 30 is provided with several inner grooves 20. The inner groove 20 is located at the upper part of the crystallizer close to the upper port 10 of the crystallizer.

[0044] By adding an inner groove structure on the basis of the high-speed copper tube (high-speed crystallizer), the integration is optimized, so that the shell in this section grows more uniformly, and prevents cracks in the shell that are easily caused by excessive rapid cooling.

[0045] In continuous casting production, in order to maintain the passability of molten steel and its slab, prevent the molten steel from adhering to the inner wall of the crystallizer during the condensation process, reduce the friction resistance during casting, improve the surface quality of the s...

Embodiment 2

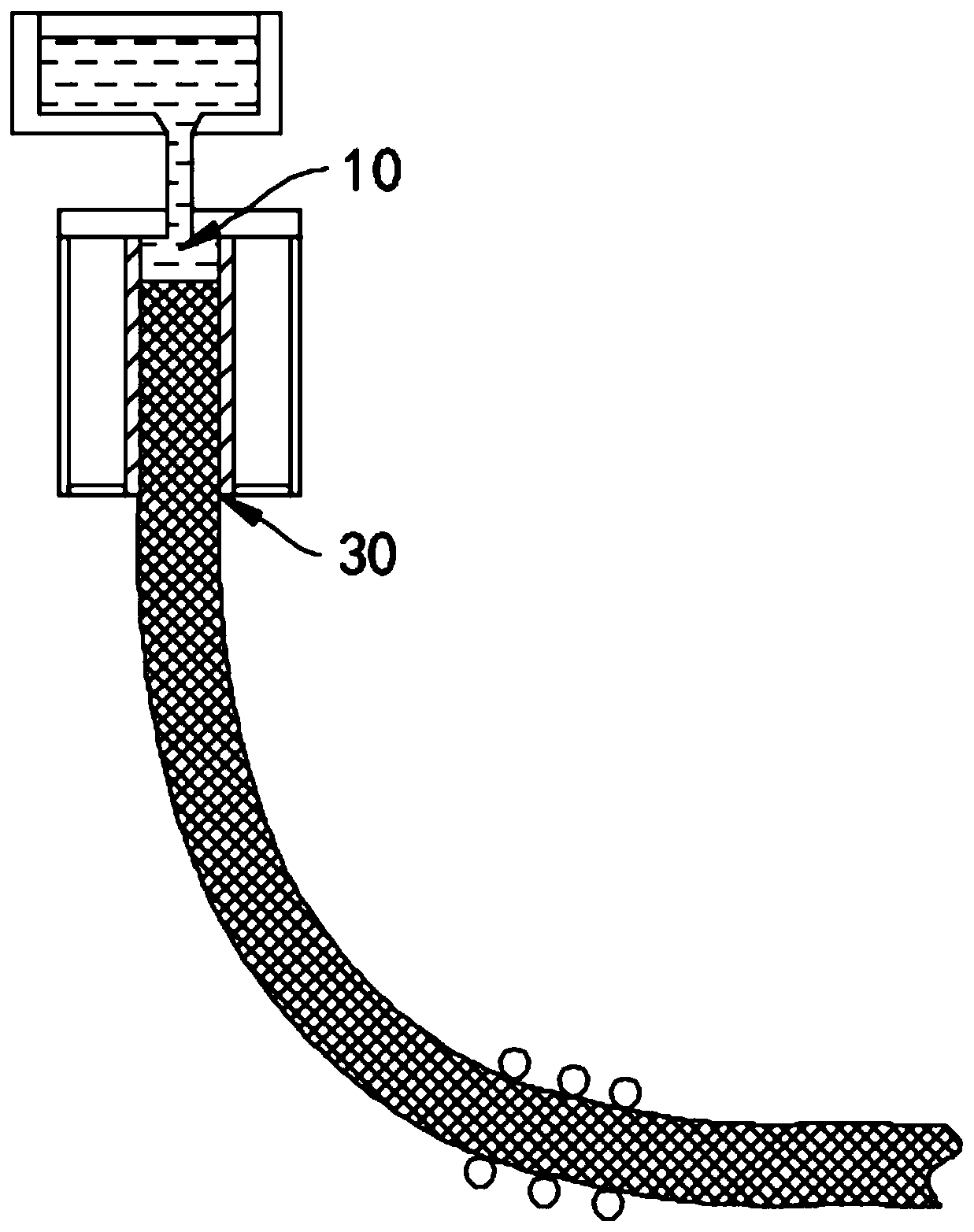

[0056] A method for promoting the growth of cast slab crystals in a crystallizer is to inject molten steel from the upper mouth of the mold, and the molten steel flows from the upper mouth of the crystallizer to the lower mouth, and undergoes three cooling steps of preliminary rapid cooling, slow cooling and shaping rapid cooling in sequence, and After forming the casting slab whose appearance is solidified slab shell and the inside is unsolidified molten steel, it is pulled out from the lower opening of the crystallizer; wherein,

[0057] The preliminary rapid cooling step is to preliminarily rapidly cool the injected molten steel to form a thin shell around the molten steel;

[0058] The slow cooling step is to slow down the solidification of the molten steel through slow cooling while continuing to form the billet shell;

[0059] The shaping quenching step is to continue to pull down the cast slab and cool the crystallized molten steel to solidify to form a slab shell of re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com