System and method for uniformly growing nitride single crystal by flux method

A technology of flux method and nitride, which is applied in the field of nitride single crystal by flux method, can solve the problems of disordered crystallization of gallium nitride, easy destruction of growth equilibrium conditions, easy introduction of new impurities and bubbles, etc., to achieve improved Growth uniformity, the effect of improving the quality of crystal growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

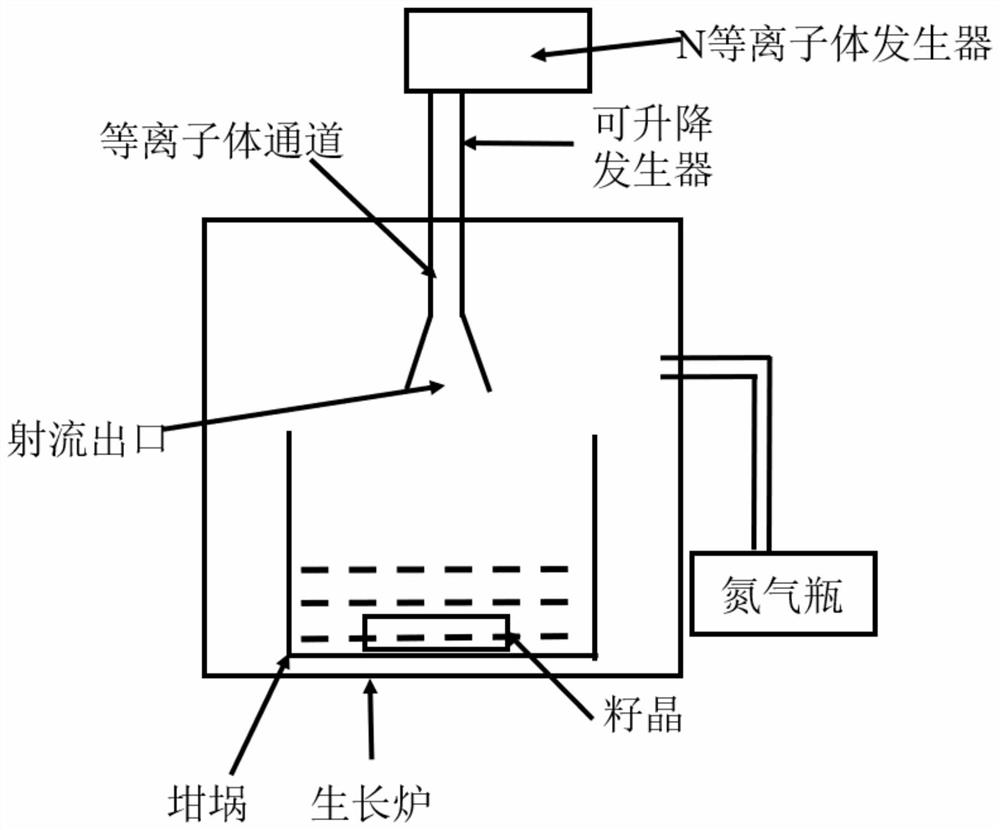

[0056] A method for uniform growth of gallium nitride single crystal by flux method, comprising:

[0057] provide as Figure 1-3 In the system shown, the seed crystal / substrate is placed in a crucible, and metal gallium, metal sodium, and carbon additives are used as growth materials, and the crucible with the growth material and seed crystal / substrate is placed in a growth furnace, wherein, The growth raw material is in a molten state, and the mass ratio of Ga-Na in the molten state growth raw material is 10:0 to 1:10, preferably 1:1 to 1:10, especially preferably 3:7 (the same below);

[0058] The temperature in the growth furnace is adjusted to about 800°C, the growth pressure is adjusted to below 5Mpa, and at the same time, a nitrogen plasma jet containing nitrogen plasma is introduced into the growth furnace with a N plasma generator, and the N plasma As a nitrogen source, liquid phase epitaxial growth of gallium nitride single crystal by flux method was carried out for ...

Embodiment 2

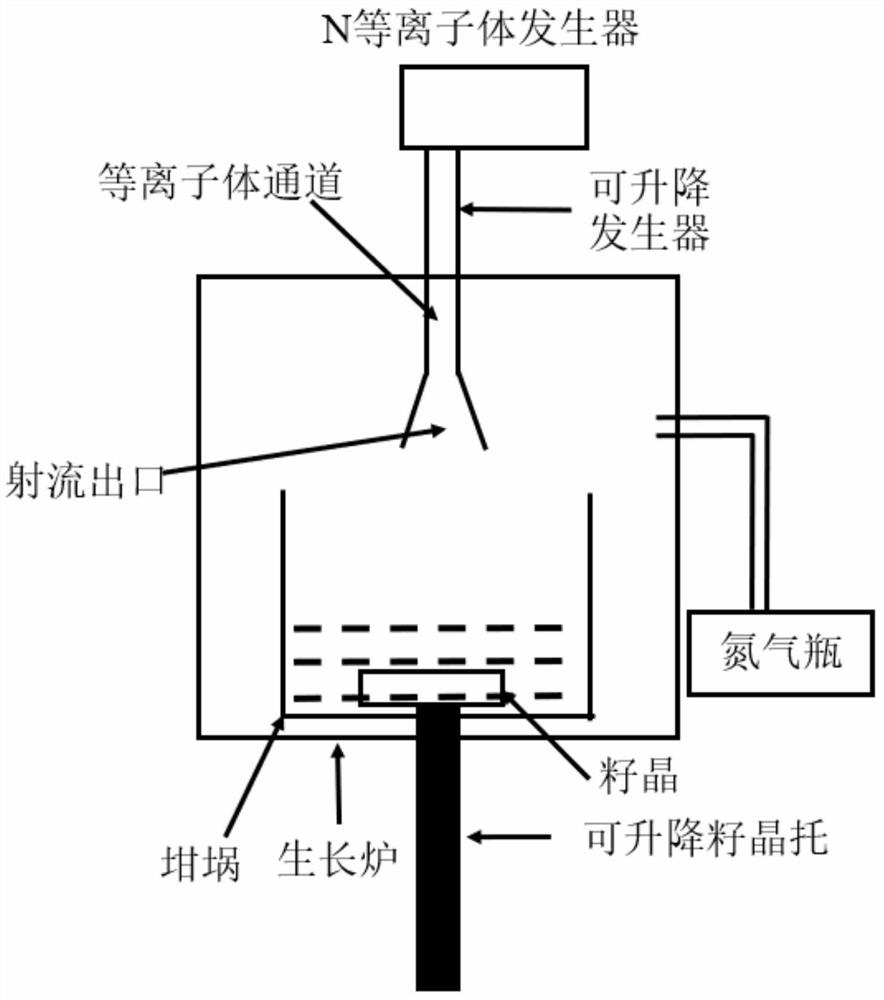

[0061] A method for uniform growth of gallium nitride single crystal by flux method, comprising:

[0062] provide as Figure 1-3 In the system in , the seed crystal / substrate is placed in the crucible, and metal gallium, metal sodium, and carbon additives are used as growth materials, and the crucible and seed crystal / substrate containing the growth materials are placed in the growth furnace. The plasma generator performs nitrogen plasma treatment on the seed crystal / substrate for 5-10 minutes to form defect sites on the surface of the substrate / seed crystal, wherein the power of the nitrogen plasma is between 1MHz and 100MHz , usually the frequency is 13.56MHZ, and the power is between 40 and 500W. Correspondingly, the gas temperature of the nitrogen plasma jet is from 25°C to several hundred degrees Celsius, and the pressure is from 0Pa to one atmospheric pressure;

[0063] The seed crystal / substrate after nitrogen plasma treatment is placed in the growth raw material, the ...

Embodiment 3

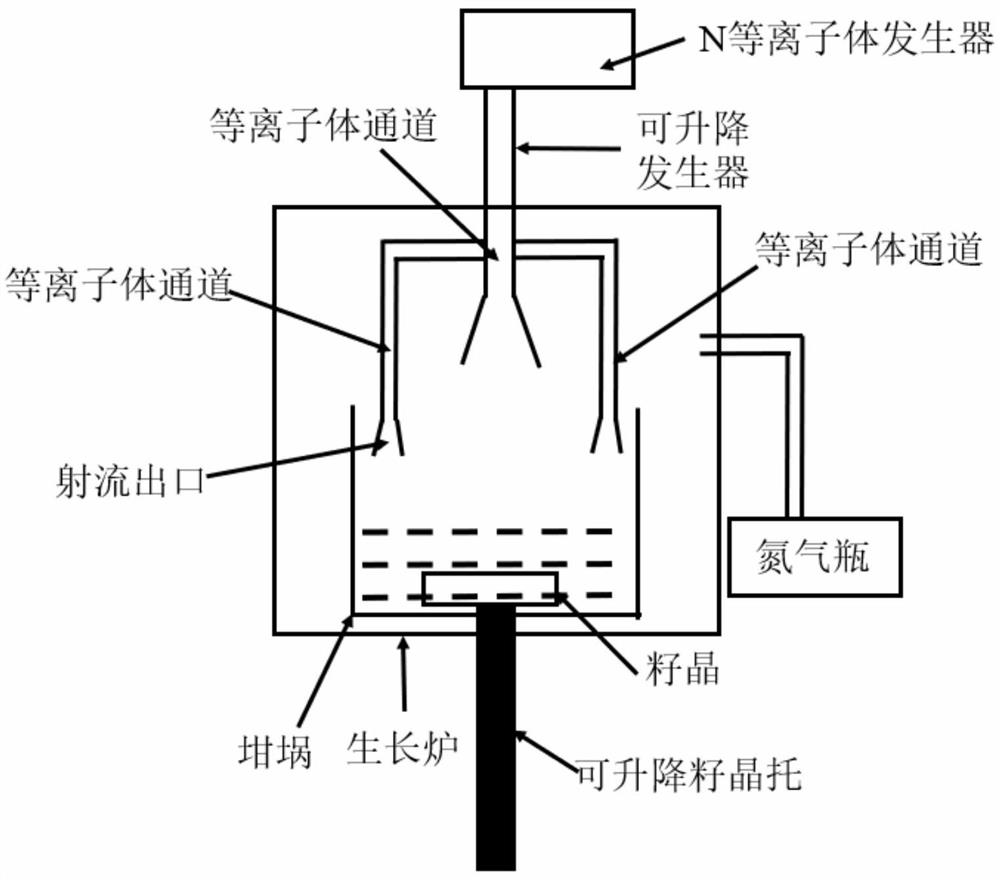

[0065] A method for uniform growth of gallium nitride single crystal by flux method, comprising:

[0066] provide as Figure 1-3 In the system in , the seed crystal / substrate is placed in the crucible, and metal gallium, metal sodium, and carbon additives are used as growth materials, and the crucible and seed crystal / substrate containing the growth materials are placed in the growth furnace. The plasma generator performs nitrogen plasma treatment on the seed crystal / substrate for 5-10 minutes to form defect sites on the surface of the substrate / seed crystal, wherein the power of the nitrogen plasma is between 1MHz and 100MHz , usually the frequency is 13.56MHZ, and the power is between 40 and 500W. Correspondingly, the gas temperature of the nitrogen plasma jet is from 25°C to several hundred degrees Celsius, and the pressure is from 0Pa to an atmospheric pressure. Then the nitrogen plasma treated seed crystal / The substrate is placed in the growth material;

[0067] The te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com