Method for adjusting uniformity of epitaxial growth

An epitaxial growth, uniform technology, applied in the direction of electrical components, circuits, semiconductor/solid-state device manufacturing, etc., can solve the problems of poor film thickness uniformity, excessive wafer growth, wafer defects, etc., to achieve improved flatness and good growth Uniformity, the effect of avoiding dislocation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The technical solutions in the embodiments of the present invention will be clearly and completely described below with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only a part of the embodiments of the present invention, rather than all the embodiments.

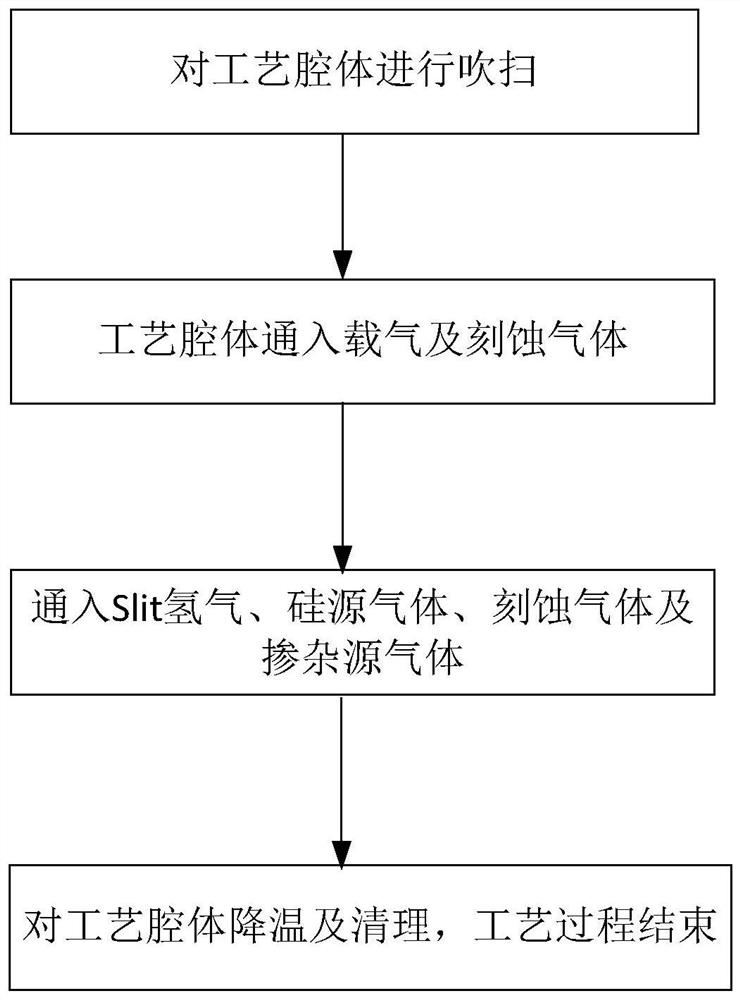

[0018] like figure 1 As shown, the method for adjusting the uniformity of epitaxial growth of the present invention comprises the following steps:

[0019] Step 1: Purging the process chamber (Chamber) to remove the residual process gas, and at the same time, the process chamber starts to heat up.

[0020] In step 2, a carrier gas and an etching gas are introduced into the process chamber, and a high temperature is used to remove the natural oxide layer of the silicon wafer, and the surface of the silicon wafer is smoothed.

[0021] Step 3: After the temperature is lowered to a typical process temperature, Slit hydrogen gas, silicon sourc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com