High-temperature cracking furnace for vacuum coating

A high-temperature pyrolysis and vacuum coating technology, which is applied in the direction of gaseous chemical plating, crystal growth, coating, etc., can solve the problems of inability to decompose, fast growth of film, and inability to make better use of raw materials, and achieve the effect of optimal control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

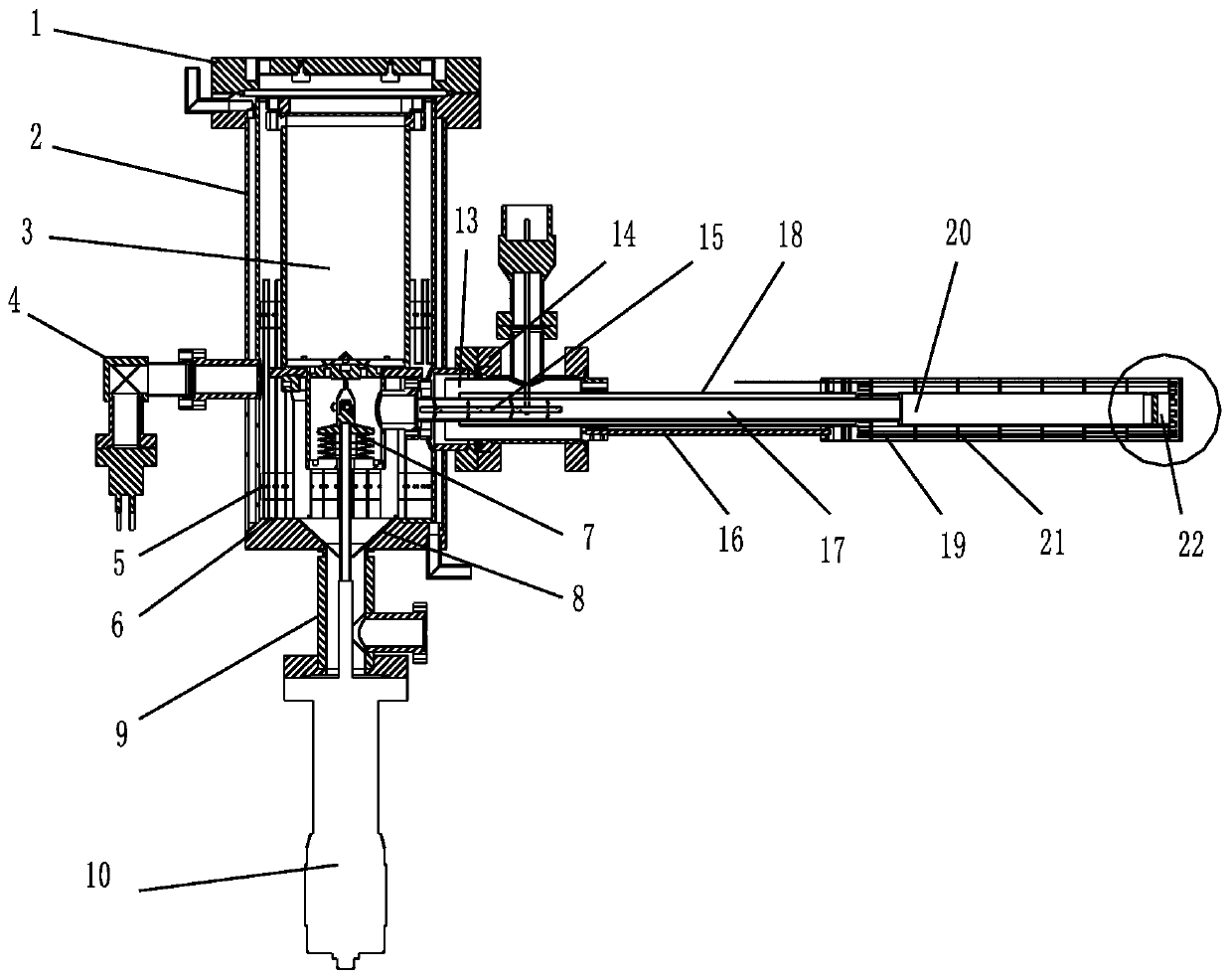

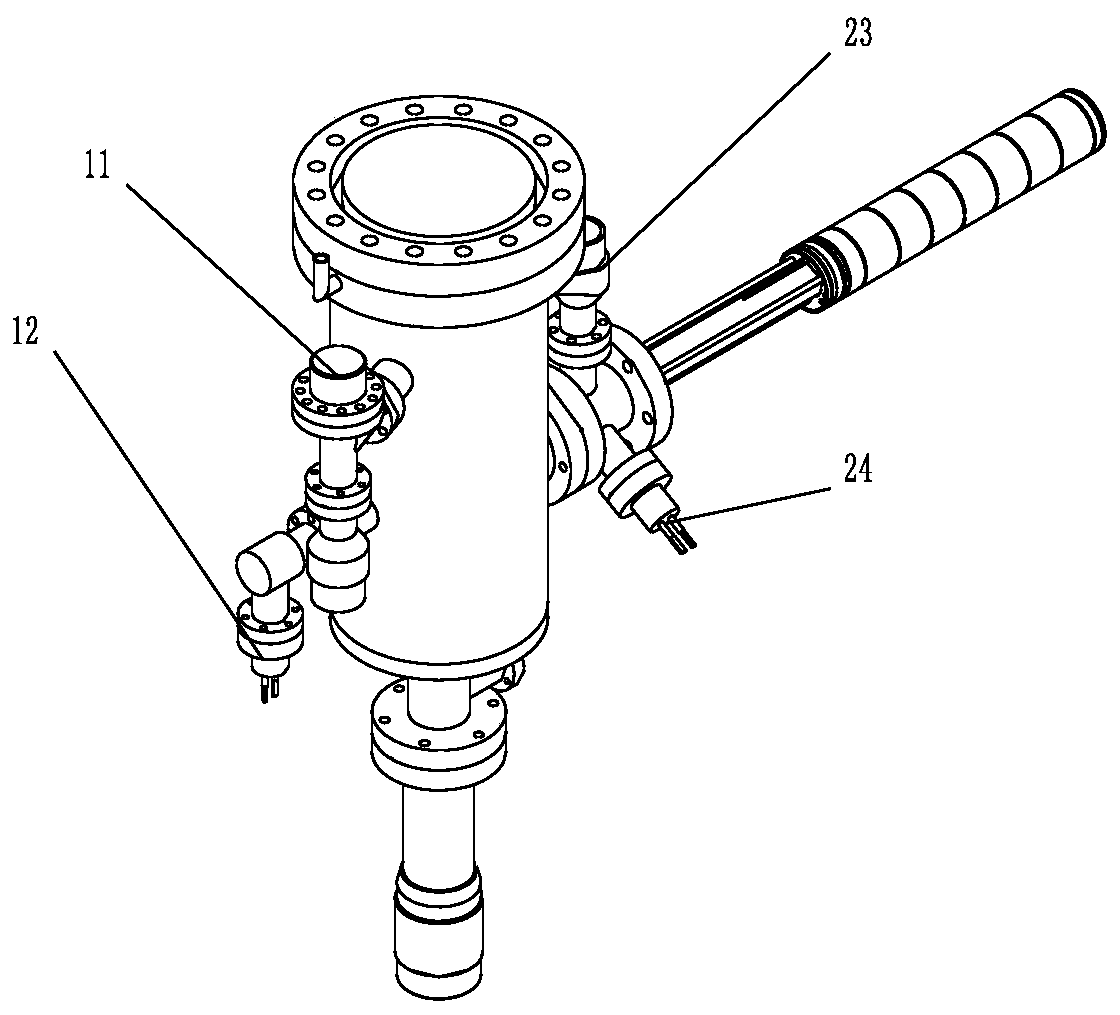

[0037] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

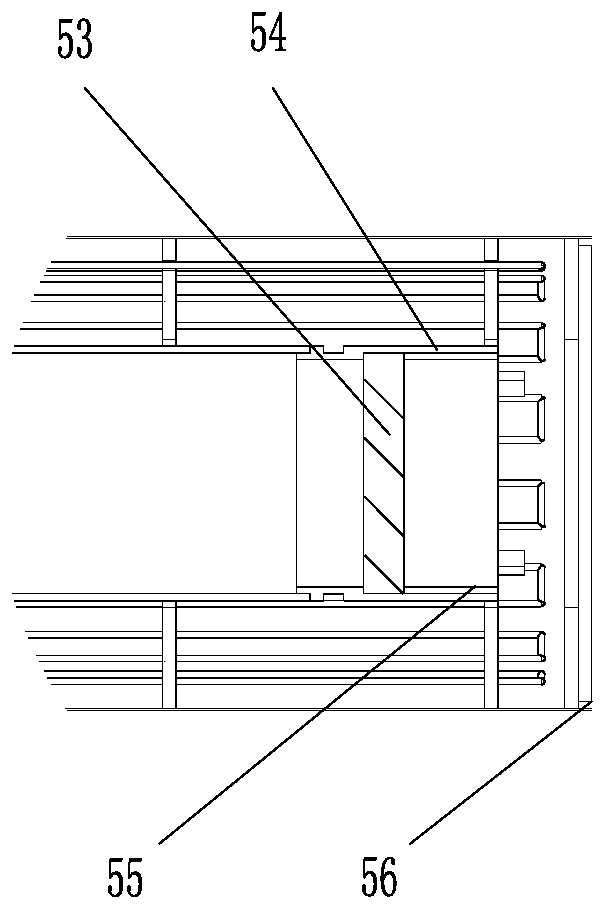

[0038] The high-temperature cracking furnace for vacuum coating of the embodiment of the present invention has a structure such as Figure 1-10 As shown, it includes low-temperature evaporation zone, control valve, high-temperature pyrolysis zone, heating and temperature measuring components, and low-temperature evaporation zone includes installation flange 1, dual-temperature zone furnace cavity 2, low-temperature crucible 3, low-temperature filament 5, and heat shield 6 , The mounting flange 1 includes a flange body 25 , a shielding sheet 26 is embedded in the flange body, and the shielding sheet plays a role of heat insulation, and is fixed in the flange body 25 by a compression screw 27 .

[0039] The double-temperature zone furnace cavity 2 includes a water outlet 28, a water-cooling block 29, a flange 30, a cavity branch pipe 31, an upper flange 32, a water inlet ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com