Full hydraulic double-motor energy-saving reinforcing steel bar straightening and cutting machine

A hydraulic motor and dual motor technology, applied in the field of steel bar processing equipment, can solve the problems of inability to eliminate tensile deformation and internal organizational structure, shorten the service life of equipment, affect the quality of construction projects, etc., and achieve a novel and unique straightening method, which is convenient for personnel. and production management, the effect of reliable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

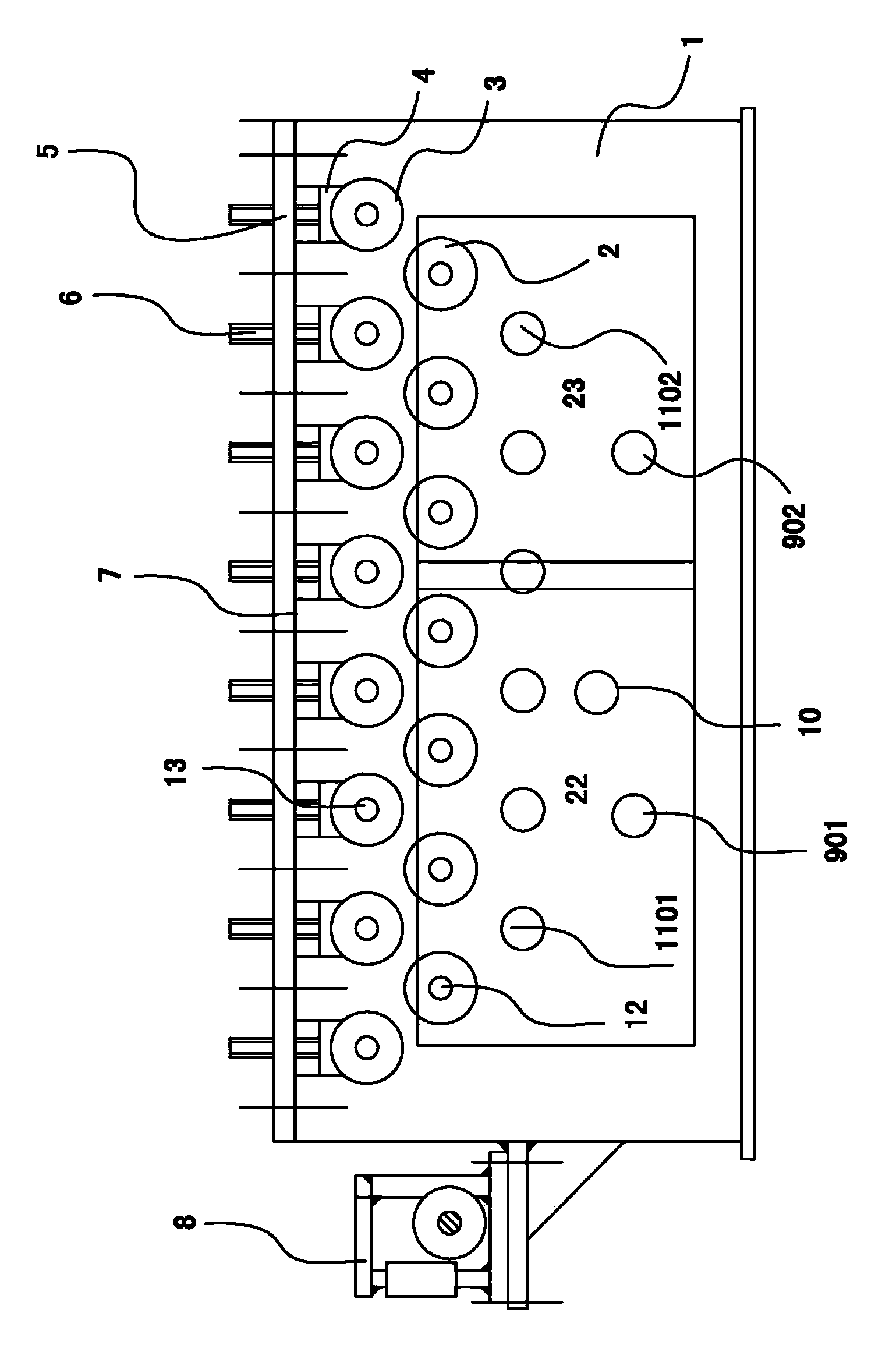

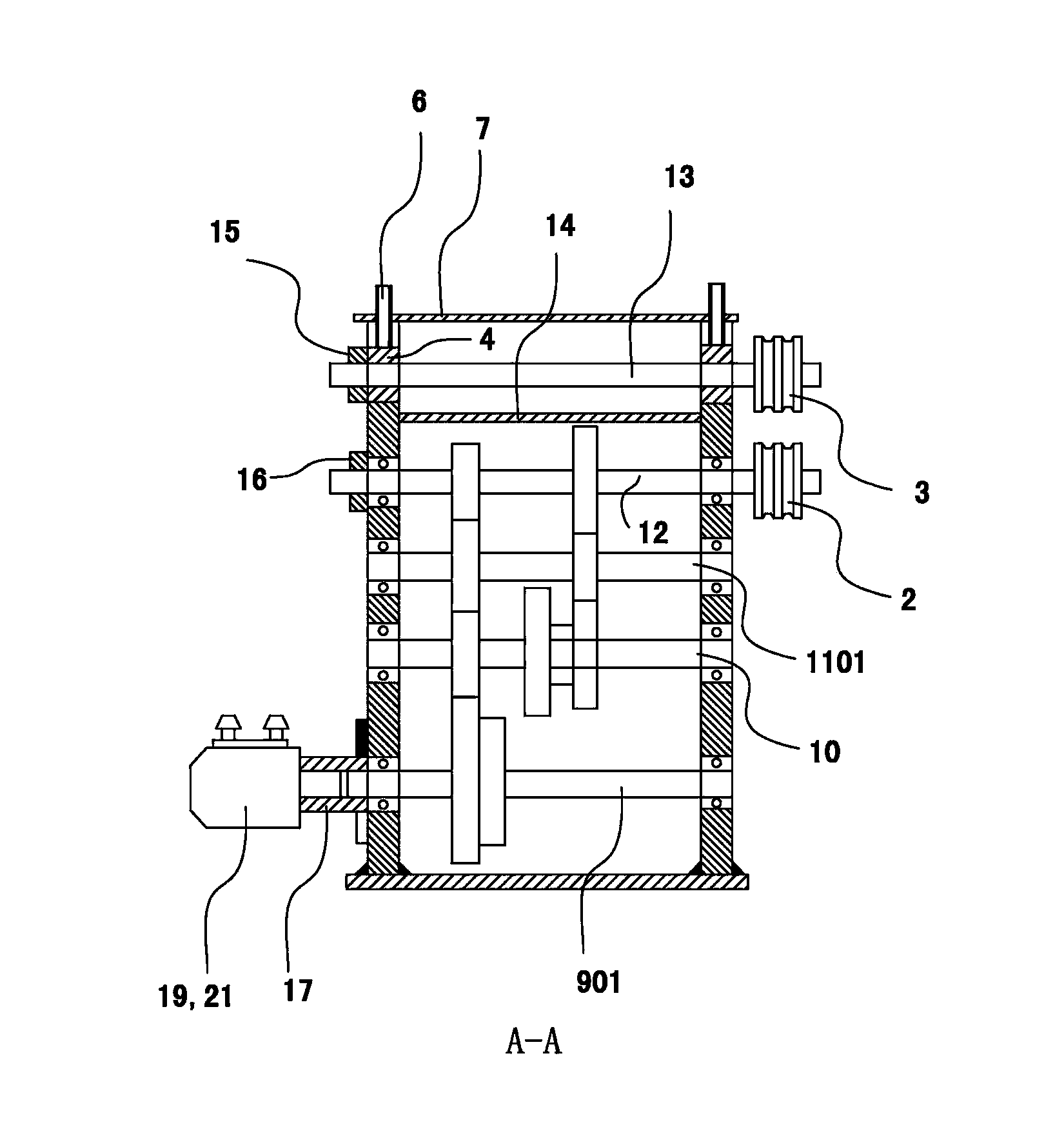

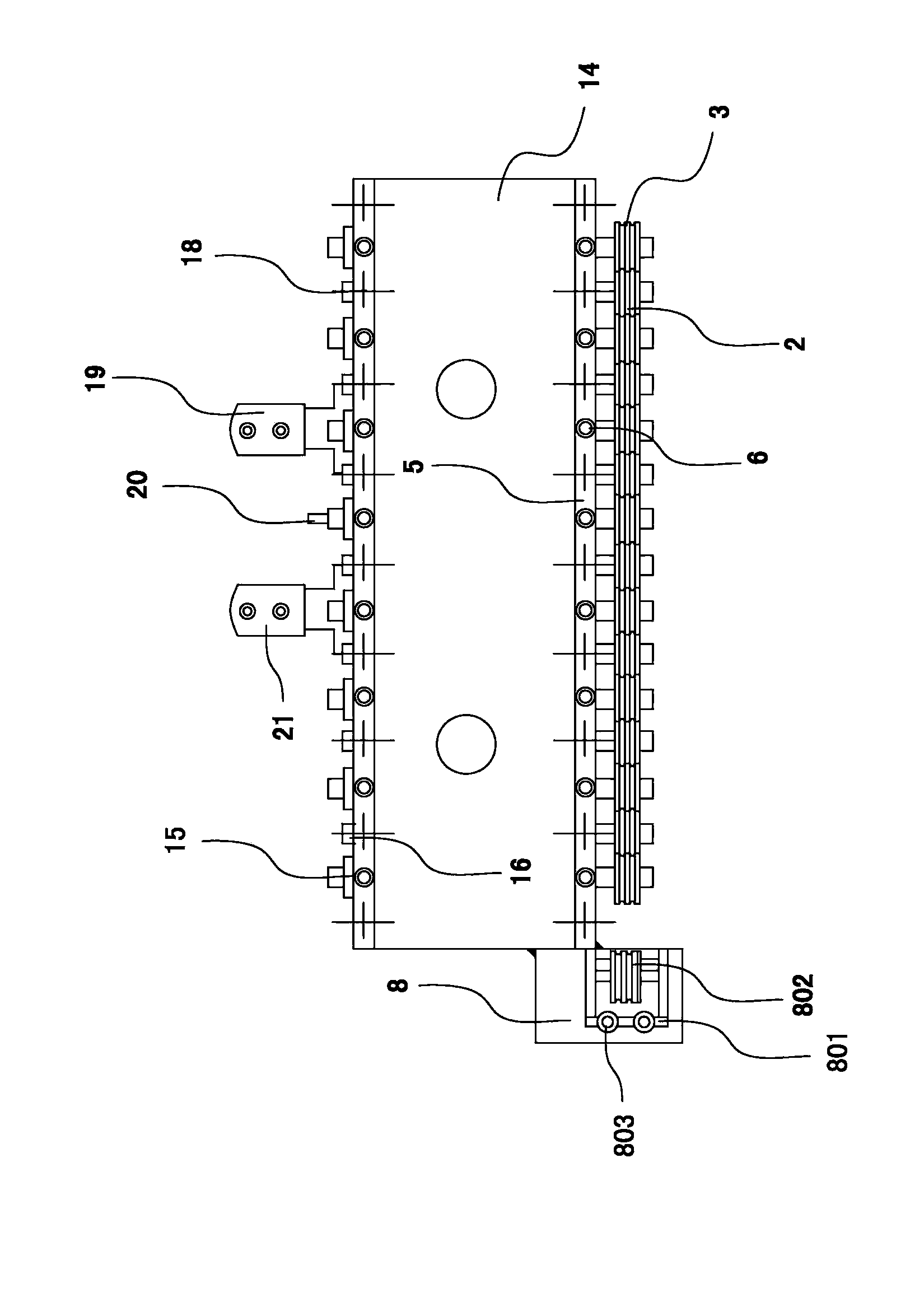

[0019] As shown in the figure, the full-hydraulic dual-motor energy-saving steel bar straightening and cutting machine includes a box body 1, a first rotating shaft system 22, a second rotating shaft system 23, and an active straightening roller connected to the active straightening roller 2 at the end. The gear shaft 12, the passive straightening roller shaft 13 connected to the passive straightening roller 3 at the end, the steel bar inlet guide device 8, the first hydraulic motor 19 and the second hydraulic motor 21; the first rotating shaft system 22, the second hydraulic motor The two rotating shaft systems 23, the active straightening roller gear shaft 12 and the passive straightening roller shaft 13 are placed in parallel in the box body 1 and are connected to the box body 1; the power output terminal of the first hydraulic motor 19 is connected to the first rotating shaft The power input end of the shafting 22; the power output end of the second hydraulic motor 21 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com