Automatic formwork erecting and withdrawing driving device and intelligent control method

A driving device and ejection technology, which is applied in the erection/assembly of bridges, bridges, buildings, etc., can solve problems such as the inability to reduce the risk of high-altitude operations, the labor force of construction personnel, and the heavy weight of large formwork, so as to improve construction safety and simplify construction. Structure, cost-effective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

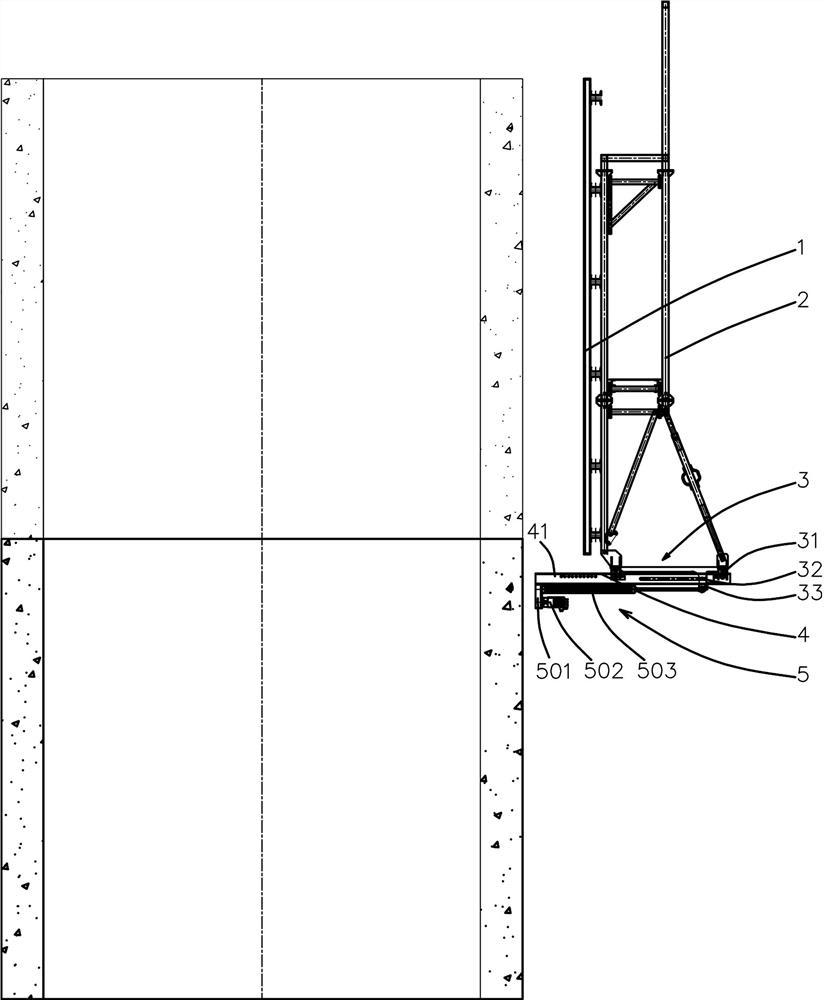

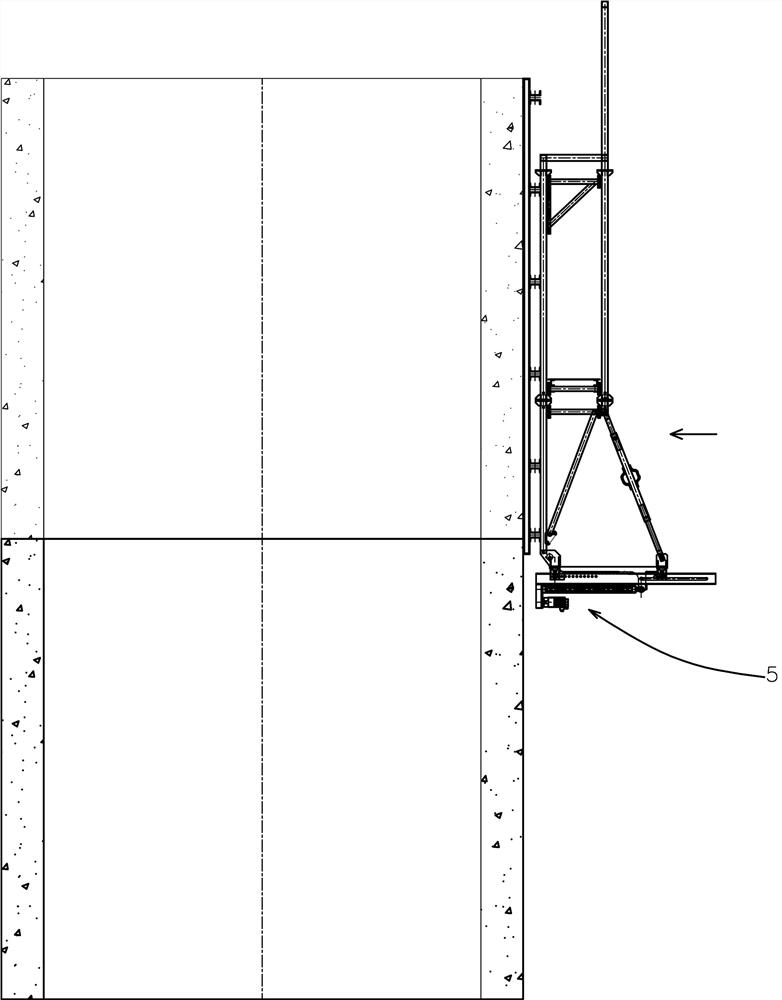

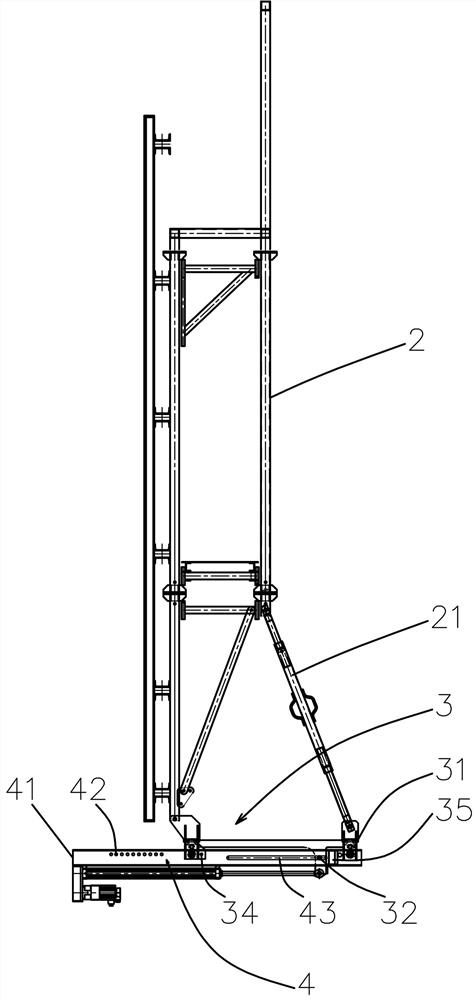

[0058] like Figures 1~3 Among them, an automatic vertical mold ejection drive device for a template, comprising an ejection platform 3 and a sliding platform 4, the ejection platform 3 is used to connect with the template support system 2, and the ejection platform 3 is slidably connected with the sliding platform 4;

[0059] Between the ejection platform 3 and the sliding platform 4, there is a die ejection drive mechanism 5, and the structure of the ejection ejection drive mechanism 5 is as follows: one end of the retractable screw nut mechanism 503 is connected to the ejection platform 3, and the other end is connected to the sliding platform 3. The platform 4 is connected, and the screw nut mechanism 503 is connected with the drive motor 502 . When in use, the ejection platform 3 is fixedly connected with the formwork support system 2, and is usually located at the bottom of the formwork support system 2. There is a formwork 1 on the formwork support system 2, and the sli...

Embodiment 2

[0075] On the basis of Example 1, as Figure 8 In the above, an intelligent control method for the above-mentioned automatic vertical mold ejection drive device of the template, comprising the following steps:

[0076] S1. There are multiple drive motors 502. Usually, there are multiple formwork support systems 2 at each construction location, and multiple formwork support systems 2 are provided at the bottom of the formwork support system 2 with a plurality of ejector drive mechanisms 5. In the cluster control structure, the difficulty of control is to ensure the synchronization of multiple die-removing driving mechanisms 5, and the cost cannot be unacceptable. The PLC controls each drive motor 502 to stretch out until the zero position sensor 506 is triggered, so that the screw rod 504 is at the zero position. With this structure, each drive motor 502 is reset to zero, and a higher control accuracy is obtained. With this structure, for the entire system The installation acc...

Embodiment 3

[0086] On the basis of embodiment 1 or 2, as Figure 8 In the above, an intelligent control method for the above-mentioned automatic vertical mold ejection drive device of the template, comprising the following steps:

[0087] S7, read the stroke parameters of the locking motor 351, and convert the stroke parameters into preset angle parameters;

[0088] S8. The PLC controls the action of the locking motor 351, and the locking angle sensor 357 feeds back the angle parameters. The angle parameters should be consistent with the input control parameters of the locking motor 351. If they are different, an alarm will be issued;

[0089] If the preset rotation angle parameter is reached, the locking motor 351 stops;

[0090] S9, read the travel parameters of the driving motor 502, and convert the travel parameters into preset angle parameters;

[0091] Read the torque parameters of the drive motor 502, that is, the maximum and minimum output torque ranges of the drive motor 502, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com