Method for layering, stage multi-level blasting, hole expanding and crack expanding of oil-gas-bearing rock

A technology for oil and gas rocks and oil and gas, which is applied in the field of layered, segmented and multi-stage blasting and cracking expansion of oil and gas rocks. Convenience, enhanced shale gas penetration, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

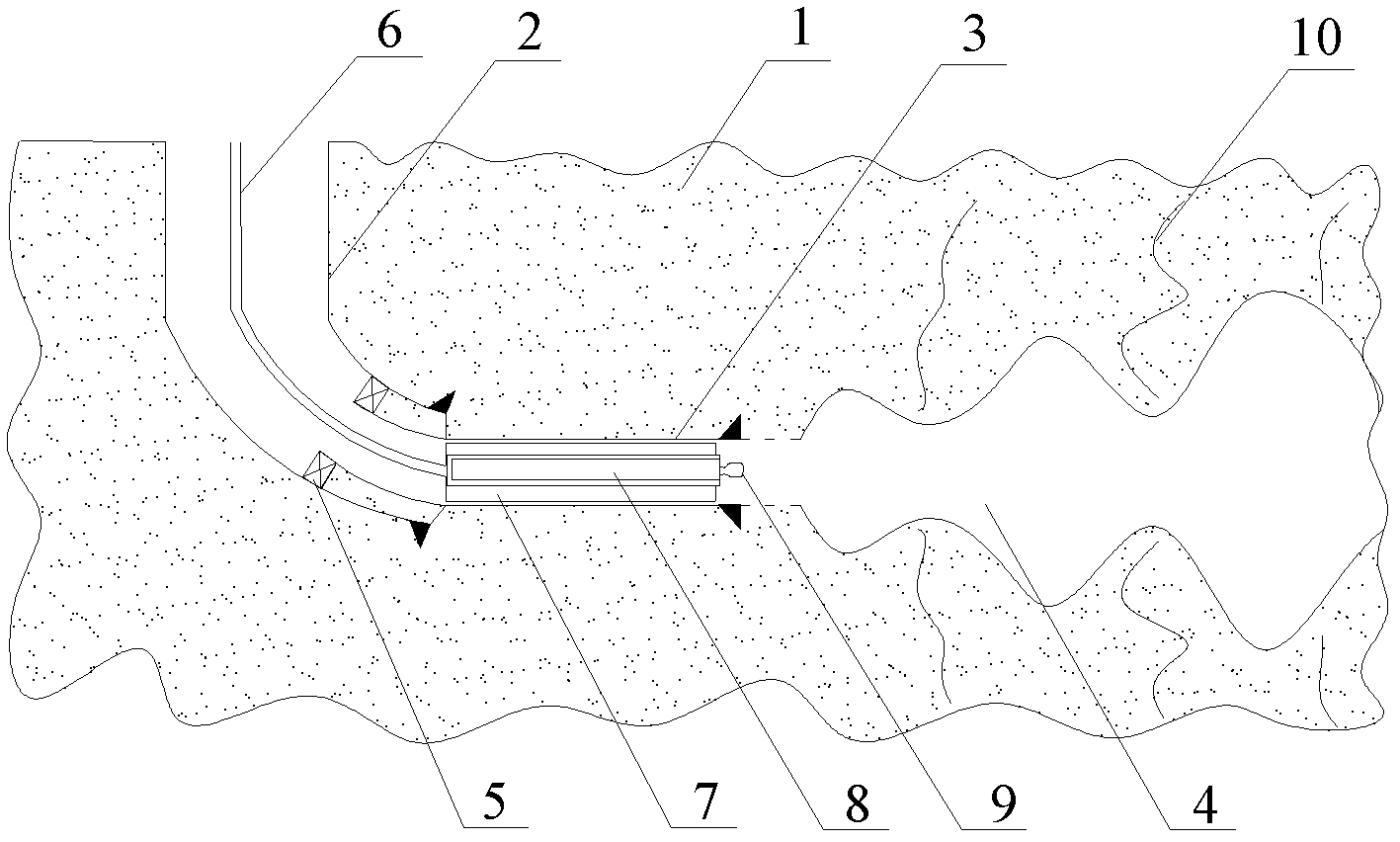

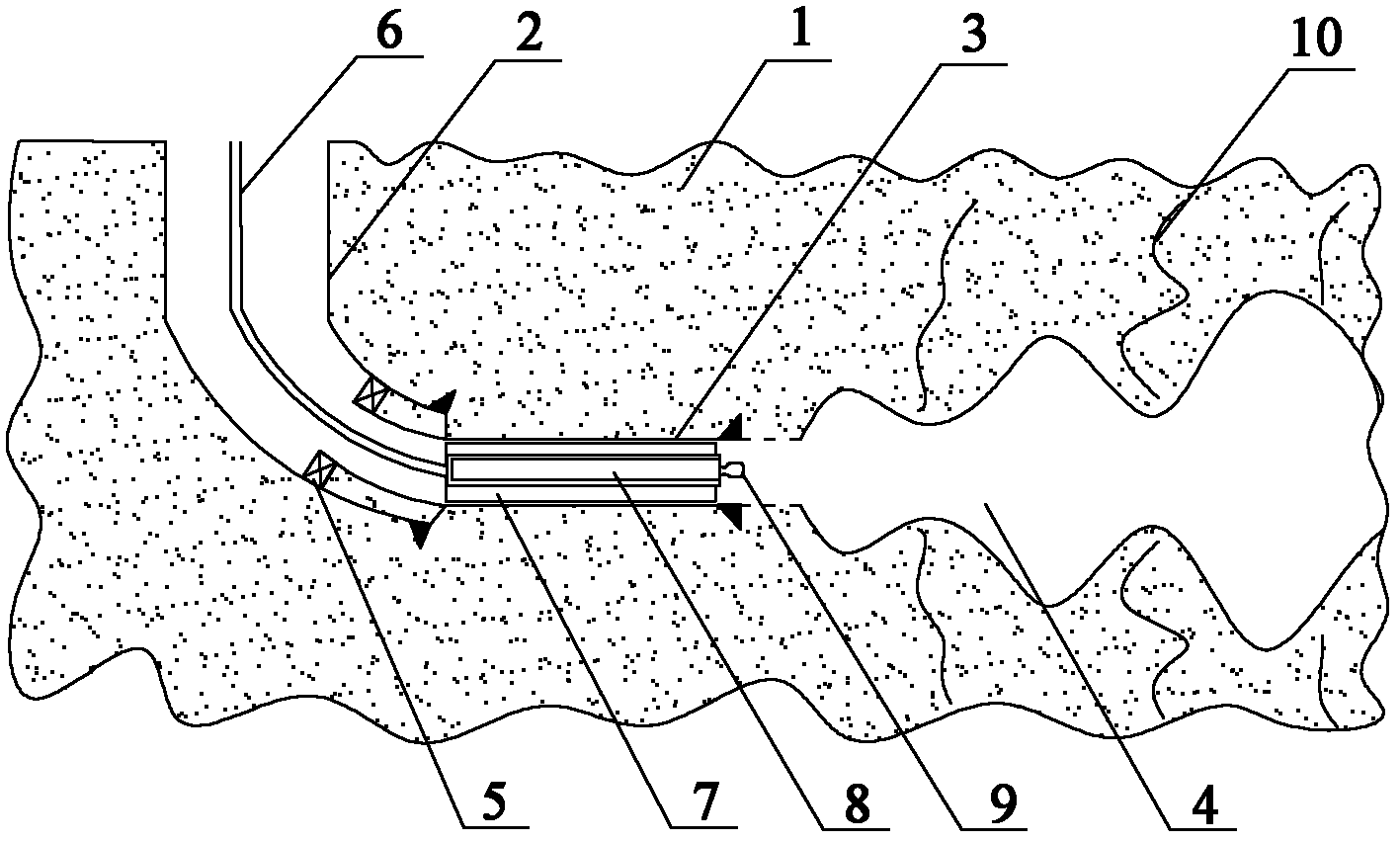

[0016] figure 1 As shown, the shale layer of a certain oil-gas-bearing rock 1 is about 20m thick. The drilling rig drills a vertical hole to the oil-gas-bearing rock 1, builds a deflection at the center of the shale layer, and drills the curved section and the horizontal section. From the vertical section to the horizontal section through the curved section , the horizontal segment extends to the predetermined position.

[0017] The casing 2 is used to contact and fix the external shale body, and the casing extends to the curved section. In the horizontal section, the light pipe 3 is used to contact and fix the external shale body, and the interlaced position of the light pipe 3 and the casing 2 is sealed with a packer 5. The light pipe 3 is set to a predetermined length in the horizontal section, and the remaining horizontal section except the light pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com