Structure for packaging organic electroluminescence element

A technology of electroluminescent components and excitation light, which is applied in the direction of electrical components, electroluminescent light sources, electric light sources, etc., and can solve problems such as not meeting economic benefits, long manufacturing process time, and increased production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

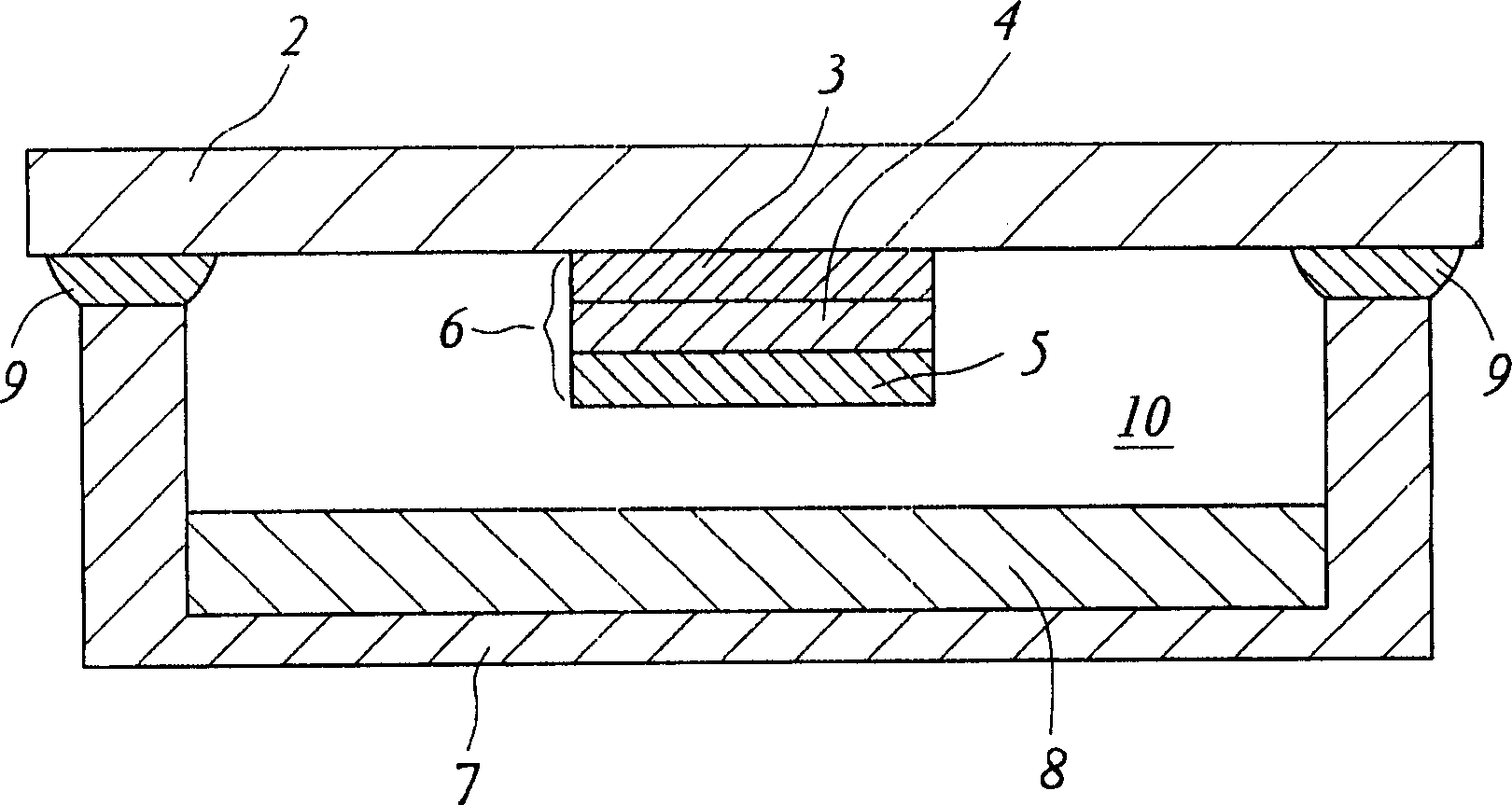

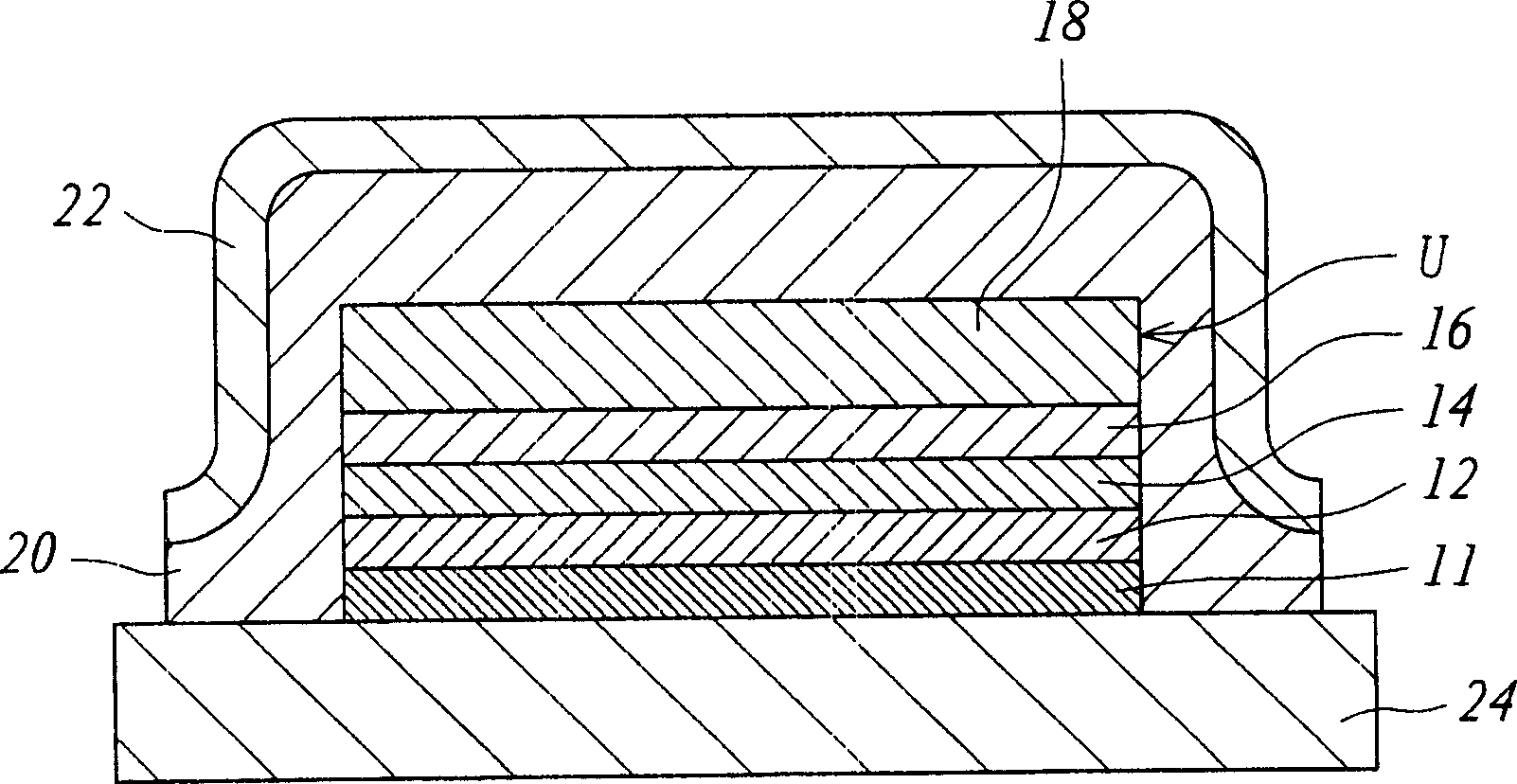

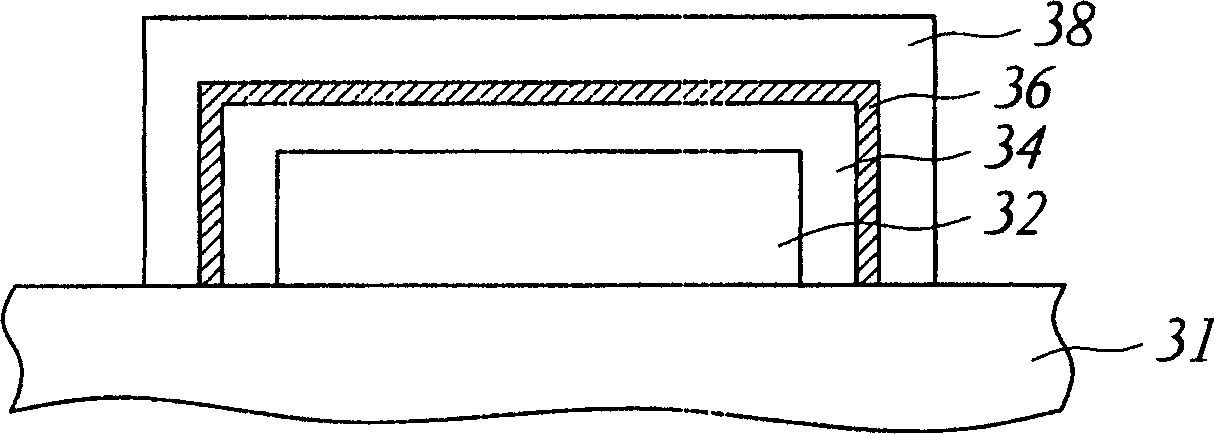

[0041] The present invention proposes a sealing structure of an organic electroluminescence device (OELD), which can not only effectively prevent moisture from invading the light-emitting device, but also release the stress of the overall structure. The present invention will be further described in detail with a preferred embodiment below.

[0042] In addition, the organic light-emitting layer of the organic electroluminescent element can be divided into: a small molecule light-emitting diode based on dyes or pigments, called OLED (organic light-emitting diode); Molecule-based light-emitting diodes are called PLEDs (polymer light-emitting diodes). It should be noted that the sealing structure in the embodiment of the present invention can be applied to sealing OLED or PLED, and there is no special limitation here.

[0043] Please refer to image 3 , which shows a schematic diagram of the sealing structure of the organic electroluminescent device according to a preferred emb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com