Joints and construction method suitable for continuous reinforced concrete pavement structure

A technology for reinforced concrete and pavement structure, applied in the direction of roads, roads, pavement details, etc., can solve the problems of large width of transverse cracks, cracks, water seepage, etc., and achieve extended service life, reduced reconstruction costs, driving comfort and safety sex-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

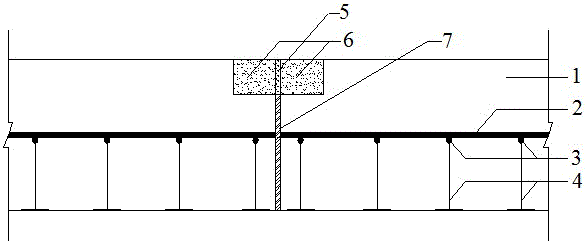

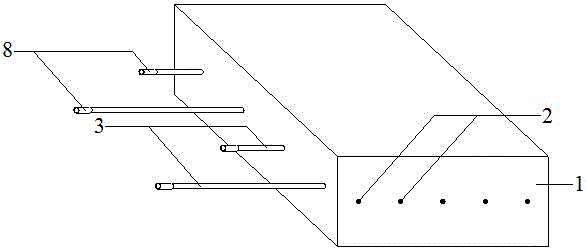

[0019] The joint and construction method applicable to the continuous reinforced concrete pavement structure of the present invention include a transverse joint, a pre-cut joint crossing a manhole cover, and a longitudinal construction joint. Referring to 1 to 2, the thickness of the cement concrete surface layer 1 is 28cm. During the construction, install the steel formwork according to the direction of the route and the height of the road surface. Set one at intervals of 150m, the width is preferably 1.2cm, divided into upper and lower parts, the depth of the upper transverse seam is set to 7cm, the lower transverse seam is set first, and the thickness of the transverse seam is placed at the position of the transverse seam (1.2cm ), the height is 21cm (the thickness of the cement concrete surface layer minus the depth of the upper transverse joint) and the polyethylene closed-cell foam caulking board 7, the longitudinal steel bar 2 traverses the polyethylene closed-cell foam ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com