Amorphous composite brazing filler metal for brazing ceramic and alloy

A composite solder and alloy technology, applied in the direction of welding/cutting medium/material, welding medium, welding equipment, etc., can solve the problems of component fracture, affecting the use of components, poor joint performance of brazed joints, etc., and achieve enhanced shear resistance ability, the effect of improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

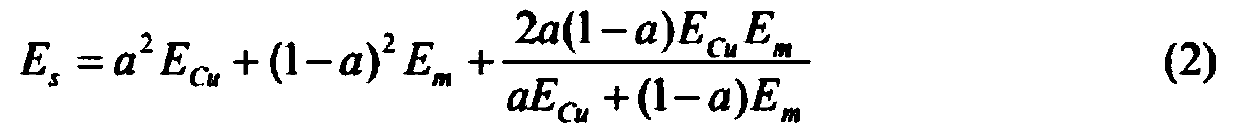

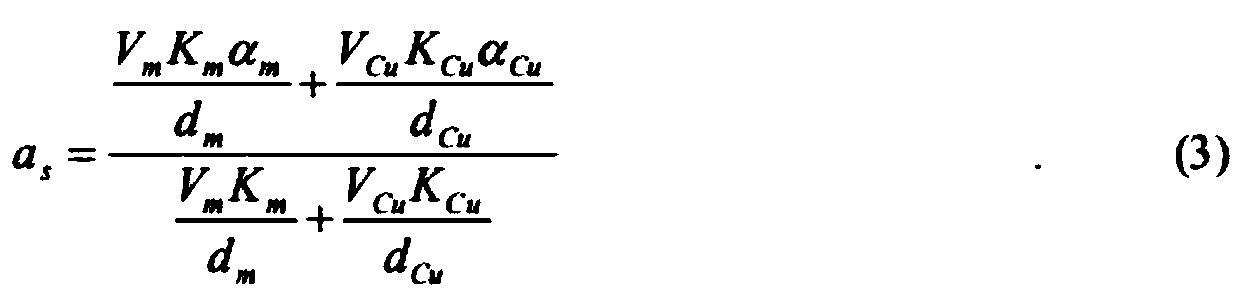

[0025] A kind of ZrB for brazing 2 -SiC ultra-high temperature ceramics and amorphous solder of Ti-6Al-4V alloy, amorphous solder includes double-layer CuTiZrNi solder and foamed Cu intermediate layer, and foamed Cu intermediate layer is filled between double-layer CuTiZrNi solder, CuTiZrNi The atomic percentages of the solder are Cu: 41.83, Ti: 30.21, Zr: 19.76, and Ni: 8.19.

[0026] A kind of ZrB for brazing 2 -The brazing method of the amorphous solder of SiC ultra-high temperature ceramics and Ti-6Al-4V alloy, comprises the following steps successively:

[0027] Step 1: Take ZrB with a volume ratio of 4:1 2 powder and SiC powder as raw material for batching, ZrB 2 The purity of the powder is 99%, the particle size is 2 μm, and the SiC powder is α-SiC, the purity is 99%, the particle size is 1 μm, take ethanol as the ball milling medium, and then ZrB 2 The powder and SiC powder raw materials are mixed and placed in a planetary grinder for ball milling with zirconia bal...

Embodiment 2

[0033] The difference between this embodiment and embodiment 1 is that the heat preservation time in step 5 is 20min.

[0034] Others are with embodiment 1.

Embodiment 3

[0036]The difference between this embodiment and embodiment 1 is that the heat preservation time in step 5 is 50min.

[0037] Others are with embodiment 1.

[0038] The present invention adopts above-mentioned 3 embodiments, and the content of further experimental analysis is as follows:

[0039] When the brazed joint was held at 910°C for 10 minutes, no obvious pores were observed in the brazed joint; at this time, the thickness of the weld was about 150 μm, which was smaller than the thickness of the foamed Cu intermediate layer, because the foamed Cu intermediate layer has a large porosity, Therefore, the foamed Cu interlayer is easily compressed during the brazing process, so after brazing, the 0.5 mm thick foamed Cu interlayer is compressed to only about 150 μm;

[0040] When the brazed joint is kept at 910°C for 20 minutes, the sample with the foamed Cu interlayer can obtain a brazed joint without any defects, and two continuous reaction layers are detected on both side...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com