Control method for numerical control machining deformation of wall panel parts

A technology of deformation control and wall panels, applied in metal processing equipment, metal processing machinery parts, manufacturing tools, etc., can solve problems such as easy deformation, uneven removal amount, affecting aircraft manufacturing efficiency and quality, and achieve control of processing deformation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

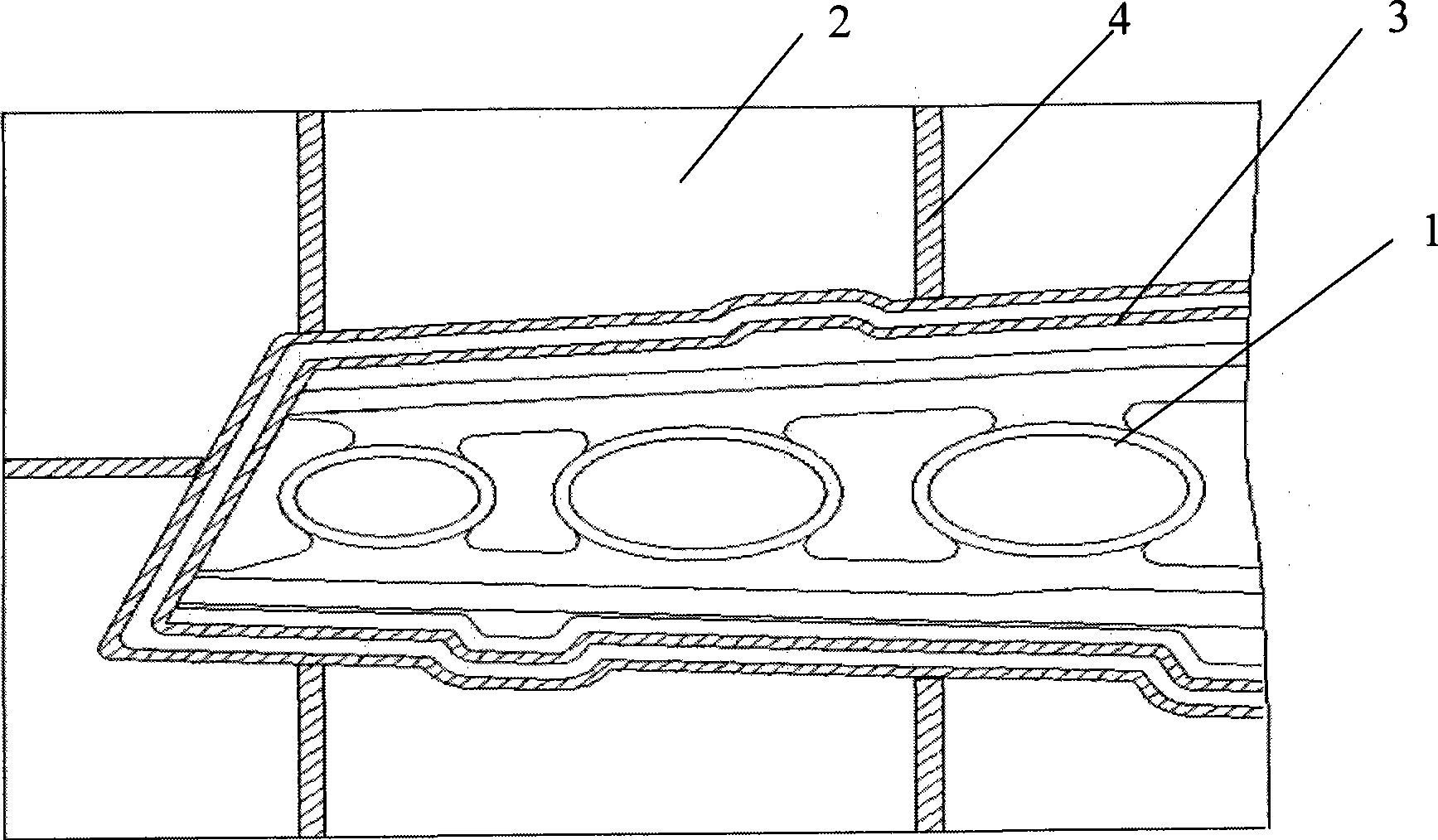

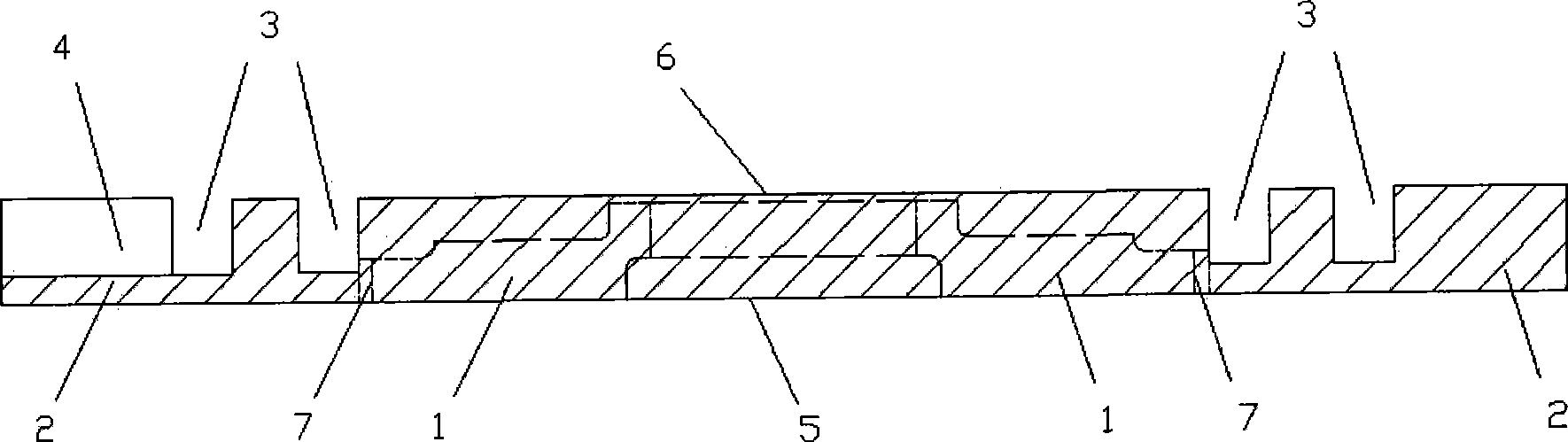

[0011] Referring to accompanying drawing, the panel part 1 among the embodiment is the panel part of an aircraft wing, and this part is long 12460MM, wide 2500MM, thick 17MM. For processing this part, the wall panel material 2 selected is a stretched plate to be processed, with a length of 13000MM, a width of 2600MM and a thickness of 19MM. The wallboard material 2 has an outer surface 5 and an inner surface 6. During numerical control machining, the theoretical shape of the wallboard part 1 is projected onto the wallboard material 2 to be processed, and the part outside the contour line 7 is the process margin during the processing material part. The processing of parts is to process the outer surface 5 of the wall panel material into a flat reference plane, that is, the outer surface of the wall panel part 1, and remove the remaining material from the inner surface 6 of the wall panel material according to the theoretical shape data of the wall panel part 1. In order to con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com