Silicon substrate top emission organic light emitting microdisplay and method for producing same

A technology of microdisplay and organic light-emitting layer, which is applied in static indicators, semiconductor/solid-state device manufacturing, instruments, etc., can solve the problems of not pointing out the structure and manufacturing process of silicon-based microdisplays, and easily introducing pollution and pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

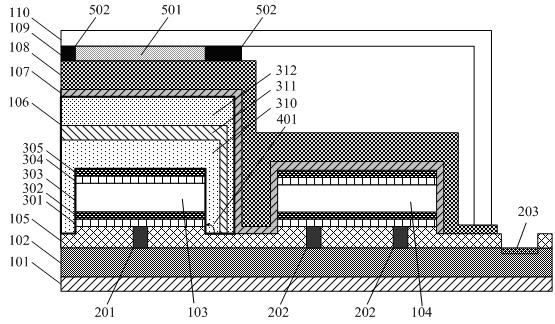

[0057] see figure 1 , the silicon-based top-emitting organic light-emitting microdisplay: the organic light-emitting device is fabricated on the surface of the silicon-based chip, the driving circuit and the control circuit of the organic light-emitting device are integrated in the silicon-based chip, and the light source generated by the organic light-emitting device passes through the top of the microdisplay Issued externally, its structure includes:

[0058] (1) A single crystal silicon substrate 101 and a driving circuit layer 102;

[0059] (2) a top via layer 105 for generating vias;

[0060] (3) organic light-emitting pixel anodes 103 arranged in an array, and the pixel anodes 103 have a vertical five-layer dielectric structure;

[0061] (4) One or more organic light-emitting common cathode electrodes 104;

[0062] (5) The via hole 201 located under the pixel anode 103 and the via hole array 202 located under the common cathode electrode 104;

[0063] (6) Bonding are...

Embodiment 2

[0071] This embodiment is basically the same as Embodiment 1, and the special features are as follows:

[0072] The current path of organic luminescence is: external power supply -> positive power supply pin of bonding area 203 -> driving circuit layer 102 -> through hole 201 -> pixel anode 103 -> organic layer 106 -> transparent cathode layer 107 -> total Cathode electrode 104 -> through hole array 202 -> driving circuit layer 102 -> negative power supply pin of bonding area 203 -> external power supply. The current flowing through a single anode pixel does not exceed 80 nanoamps.

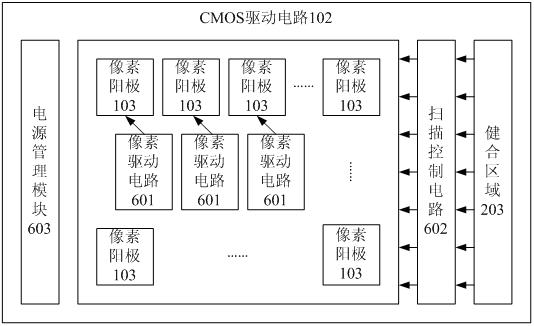

[0073] The driving circuit layer 102 is manufactured using a CMOS integrated circuit process, and its transistor feature size is 0.6 micron, 0.5 micron, 0.35 micron, 0.25 micron, 0.18 micron, 0.13 micron or other typical deep submicron process size, and supports dual voltage or multi-voltage In the region, the analog circuit voltage range is -5V to +5V, and the digital circuit voltage range is +1...

Embodiment 3

[0095] The process flow of the silicon-based top-emitting organic light-emitting microdisplay preparation method is as follows:

[0096] (1) Manufacture the driving circuit 102 on the single crystal silicon substrate 101 according to the CMOS process.

[0097] (2) Using the mask plate of the via layer, the top via layer 105 , the via holes 201 and the via hole array 202 are manufactured by chemical vapor deposition.

[0098] (3) Make the pixel anode 103 and the common cathode electrode 104 using the top metal layer mask. This process includes cleaning, dehydration, coating, glue coating, photolithography, development, etching, and glue removal. The coating process includes physical vapor phase deposition and chemical vapor deposition.

[0099] (5) Using a bonding layer mask, etch the top via layer to form a bonding region 203 .

[0100] (6) Cutting the wafer to form a micro-display silicon-based chip.

[0101] (7) Using an organic layer mask and a vacuum evaporation process...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Unit area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com