Black solder resist compound and cured product thereof

A technology of solder resist and composition, applied in the field of solder resist, which can solve the problems of low exposure sensitivity and resolution, insufficient photocuring, and difficulty in obtaining high resolution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~4 and comparative example 1~3

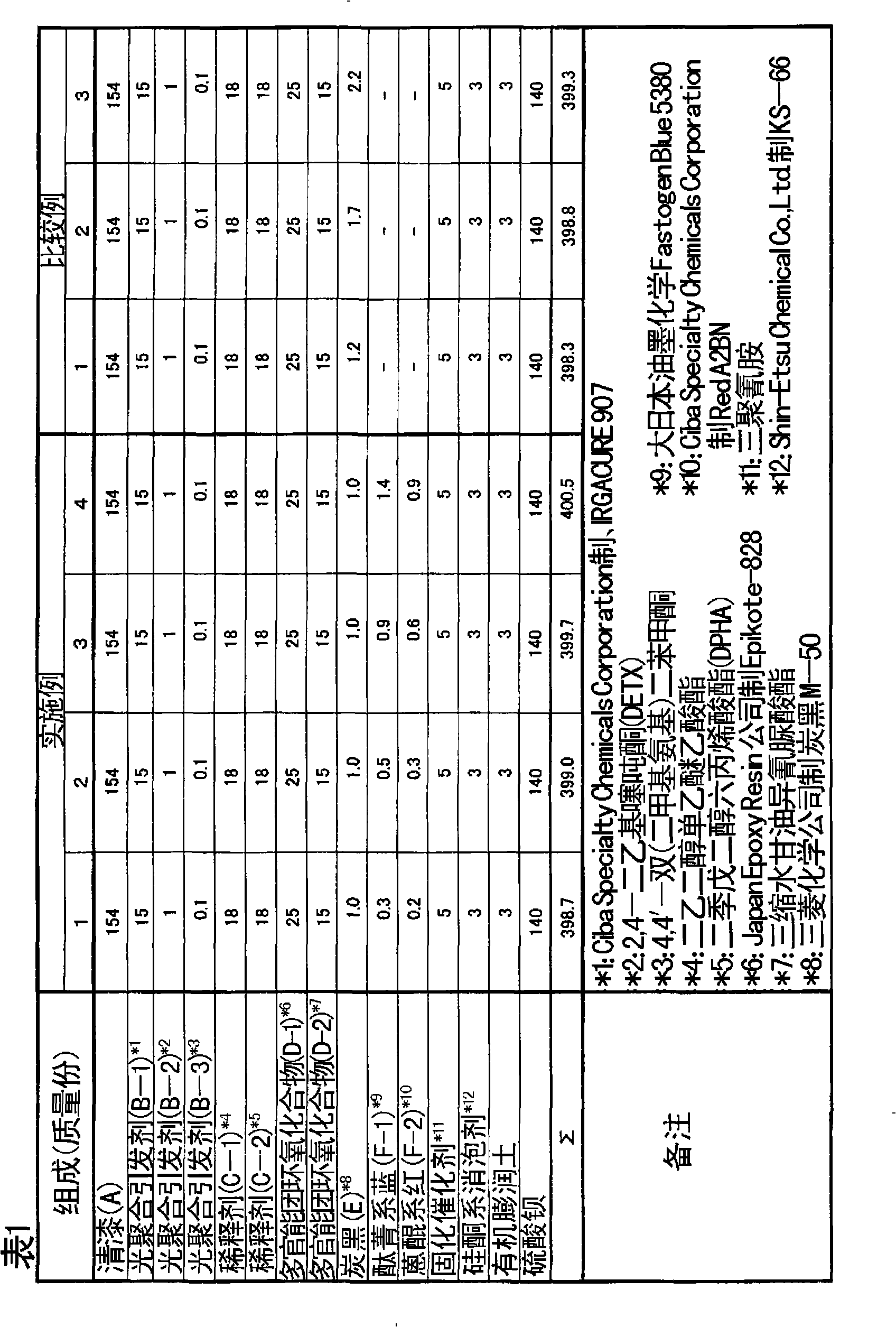

[0098] The varnish A obtained in the synthesis of the carboxyl group-containing resin and the components shown in Table 1 were kneaded at the compounding ratios shown in Table 1 using a three-roll mill to obtain a black solder resist composition.

[0099]

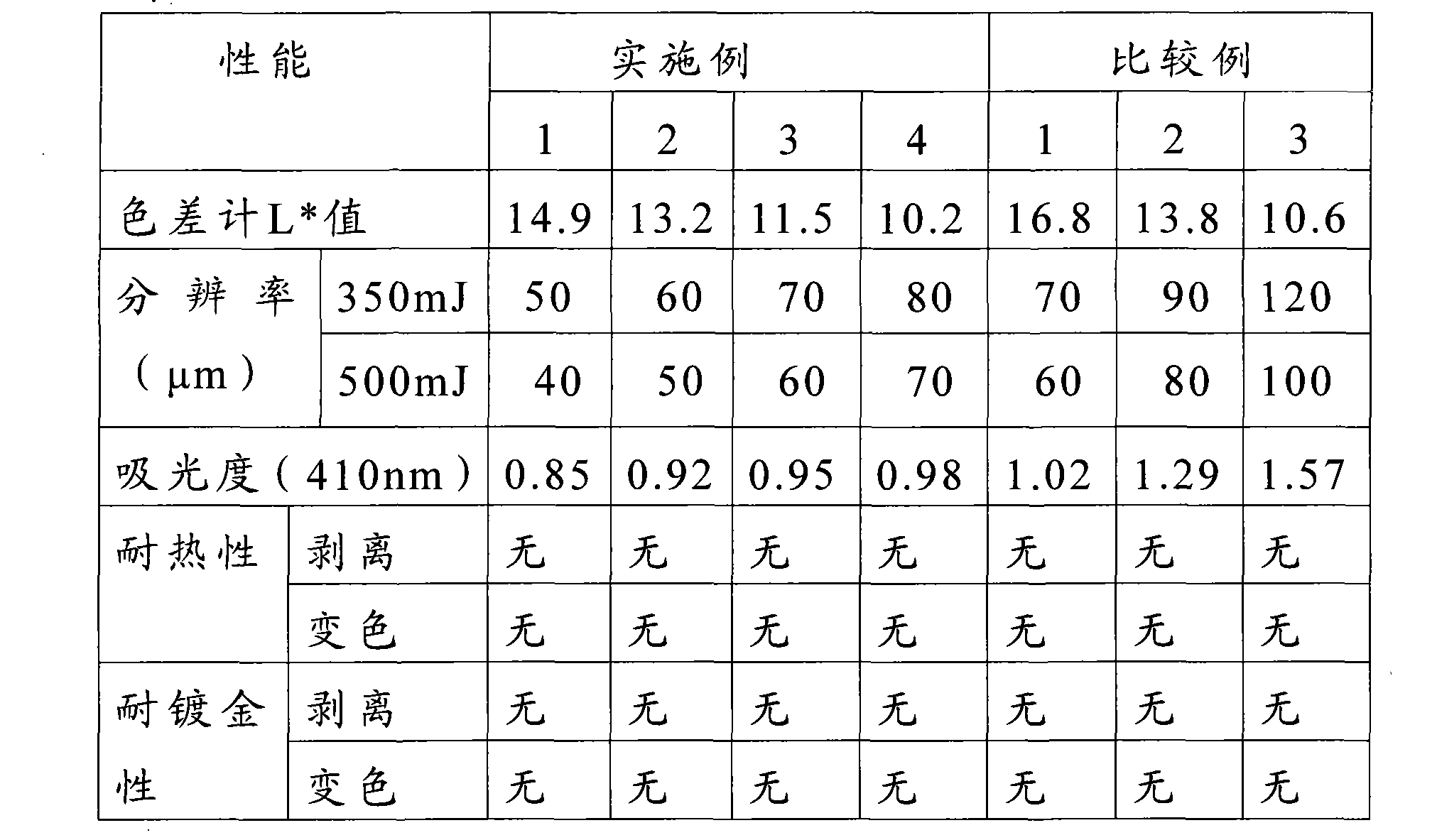

[0100] About the solder resist compositions of Examples 1-4 and Comparative Examples 1-3, performance was evaluated according to the following evaluation criteria. The results are shown in Table 2.

[0101] Performance evaluation:

[0102] (1) Color difference meter

[0103] The solder resist compositions of Examples 1 to 4 and Comparative Examples 1 to 3 were coated on the entire surface of the copper clad substrate by screen printing, and dried at 80° C. for 30 minutes in a hot air circulation drying oven, followed by , using an integrated light meter manufactured by ORC MANUFACTURING CO., LTD., on the resist at 500mJ / cm 2 The amount of light is irradiated with ultraviolet rays with a wavelength of 365nm for exposur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com