Particle of carbon-containing modified polystyrene resin, expandable particle of carbon-containing modified polystyrene resin, expanded particle of carbon-containing modified polystyrene resin, molded

A technology of polypropylene-based resin and polystyrene, applied in the field of carbon-containing modified polystyrene-based resin particles, which can solve the problems of insufficient blackness, rigidity, foaming formability, chemical resistance, heat resistance and blackness Excellent heat resistance and excellent blackness can be achieved without problems such as maintaining good degree of blackness and not being able to obtain sufficient blackness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

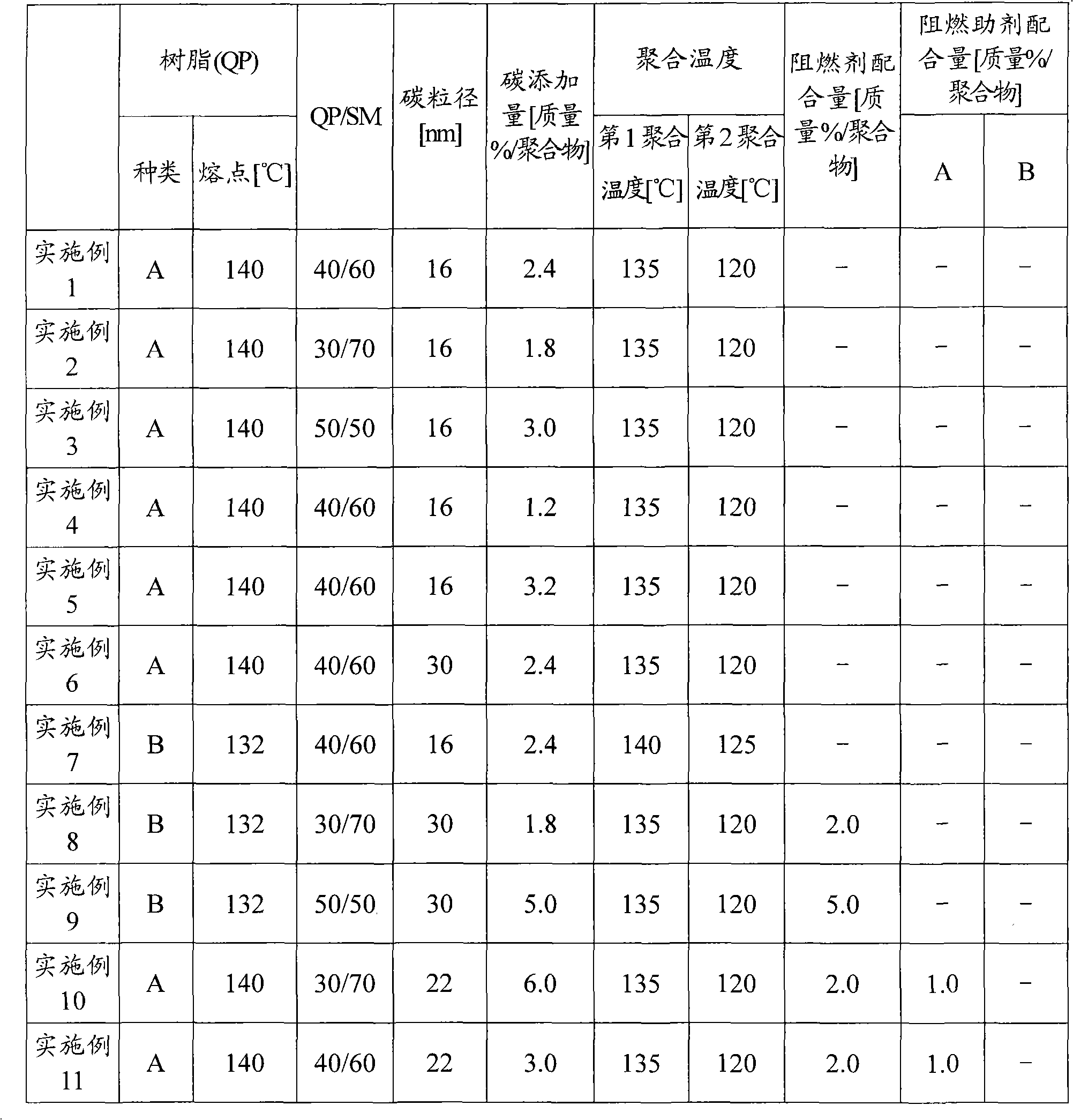

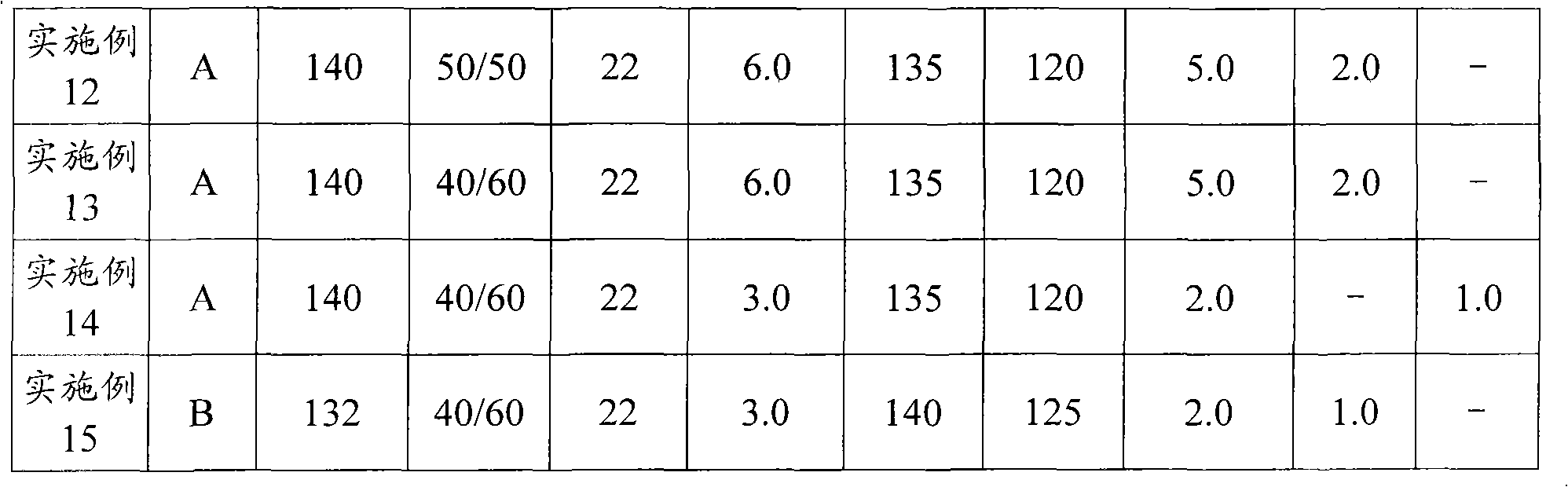

Embodiment 1

[0218] 1880 g of polypropylene-based resin (manufactured by Prime Polymer Co., Ltd., trade name "F-744NP", melting point: 140° C.) and 120 g of furnace carbon black (manufactured by Mitsubishi Chemical Corporation, trade name "#900") were mixed , the mixture was supplied to an extruder, melt-kneaded, and granulated by linear cutting to obtain a spherical (egg-shaped) containing 6% by mass of furnace carbon black in a polypropylene-based resin. Carbon polypropylene resin pellets. The carbon-containing polypropylene-based resin particles at this time were adjusted to be 80 mmg per 100 particles, and the average particle diameter was about 1 mm.

[0219] Next, in a 5L autoclave with a stirrer, 800 g of the carbon-containing polypropylene-based resin particles were added, and 2 kg of pure water, 20 g of magnesium pyrophosphate, and 0.5 g of sodium dodecylbenzenesulfonate were added as an aqueous medium, Stir and suspend in the aqueous medium, keep for 10 minutes, then raise the t...

Embodiment 2

[0228] 1880 g of polypropylene-based resin (manufactured by Prime Polymer Co., Ltd., trade name "F-744NP", melting point: 140° C.) and 120 g of furnace carbon black (manufactured by Mitsubishi Chemical Corporation, trade name "#900") were mixed , the mixture was supplied to an extruder, melt-kneaded, and granulated by linear cutting to obtain a spherical (egg-shaped) containing 6% by mass of furnace carbon black in a polypropylene-based resin. Carbon polypropylene resin pellets. The carbon-containing polypropylene-based resin particles at this time were adjusted to be 80 mmg per 100 particles, and the average particle diameter was about 1 mm.

[0229] Next, in a 5L autoclave with a stirrer, 600 g of the carbon-containing polypropylene-based resin particles was added, and 2 kg of pure water, 20 g of magnesium pyrophosphate, and 0.5 g of sodium dodecylbenzenesulfonate were added as an aqueous medium, Stir and suspend in the aqueous medium, keep for 10 minutes, then raise the te...

Embodiment 3

[0238] 1880 g of polypropylene-based resin (manufactured by Prime Polymer Co., Ltd., trade name "F-744NP", melting point: 140° C.) and 120 g of furnace carbon black (manufactured by Mitsubishi Chemical Corporation, trade name "#900") were mixed , the mixture was supplied to an extruder, melt-kneaded, and granulated by linear cutting to obtain a spherical (egg-shaped) containing 6% by mass of furnace carbon black in a polypropylene-based resin. Carbon polypropylene resin pellets. The carbon-containing polypropylene-based resin particles at this time were adjusted to be 80 mmg per 100 particles, and the average particle diameter was about 1 mm.

[0239]Next, in a 5L autoclave with a stirrer, 1000 g of the carbon-containing polypropylene-based resin particles was added, and 2 kg of pure water, 20 g of magnesium pyrophosphate, and 0.5 g of sodium dodecylbenzenesulfonate were added as an aqueous medium, Stir and suspend in the aqueous medium, keep for 10 minutes, then raise the te...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com