Microcapsule disperse black, its preparing method and dyeing method for superfine synthesized fiber and fabric

A technology of microcapsules and dispersing black, applied in dyeing methods, organic dyes, textiles and papermaking, etc., can solve the problems of ultra-fine synthetic fibers and their fabric dyeing, and achieve good blackness, pure fabric color and color fastness. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

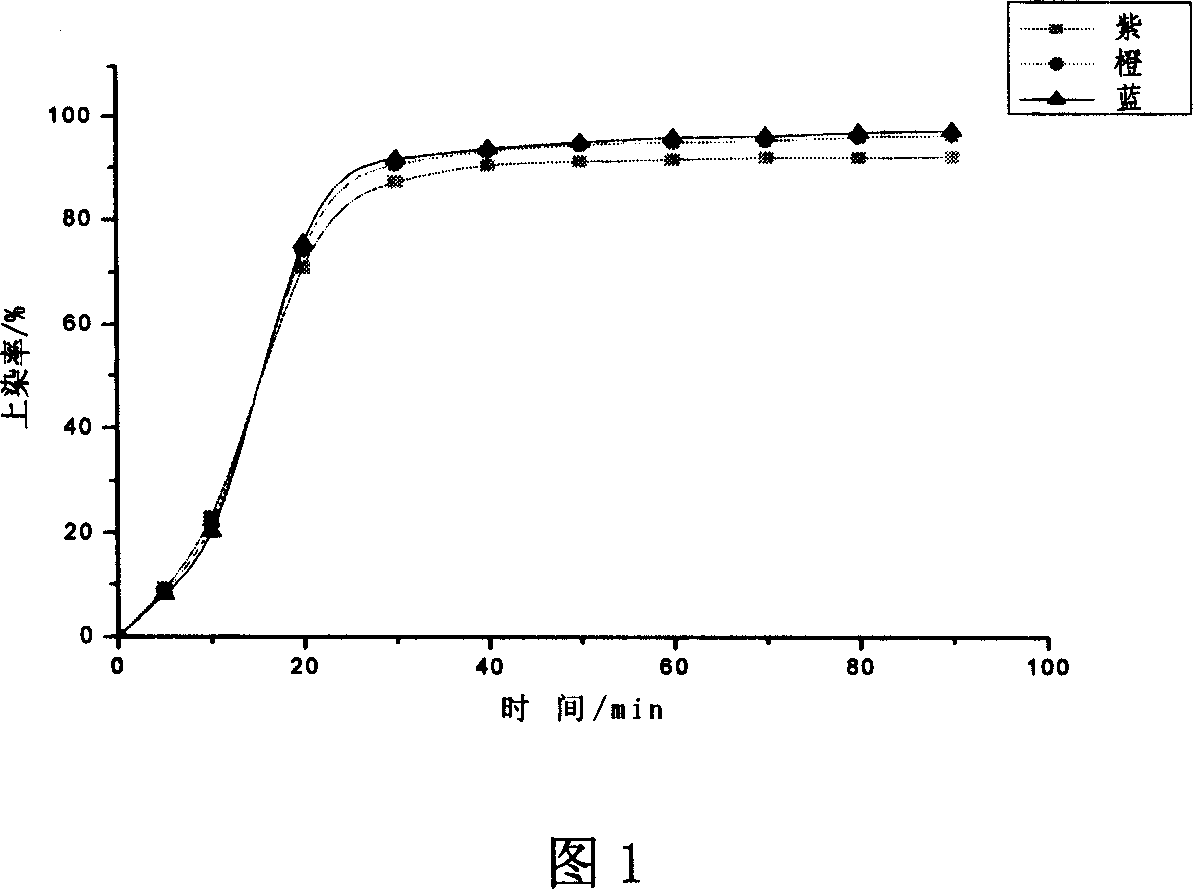

[0025] A microcapsule disperse black, which is formed by mixing three microcapsule disperse dyes of blue, purple and orange in a mass ratio of 1:1:1; the blue, purple and orange microcapsule disperse dyes are made of etherified melamine resin. The microcapsule wall material monomer uses blue, purple, and orange disperse primary color dyes as core materials respectively, and adopts in-situ polymerization to prepare blue, purple, and orange microcapsule disperse dyes. The average particle size of the microcapsules is 15-40 μm.

[0026] The preparation method of above-mentioned microcapsule dispersion black is:

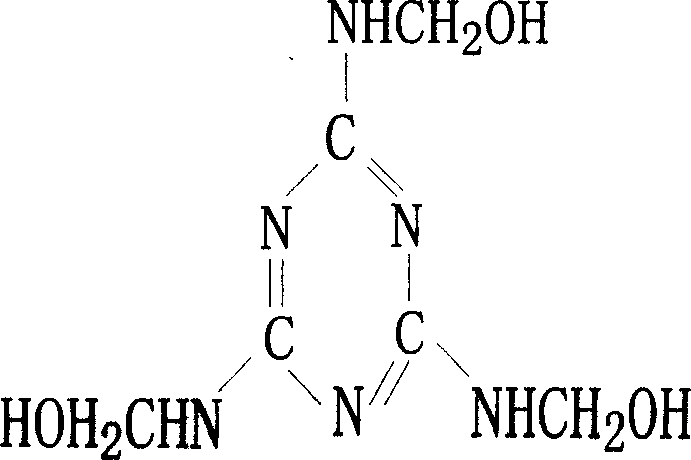

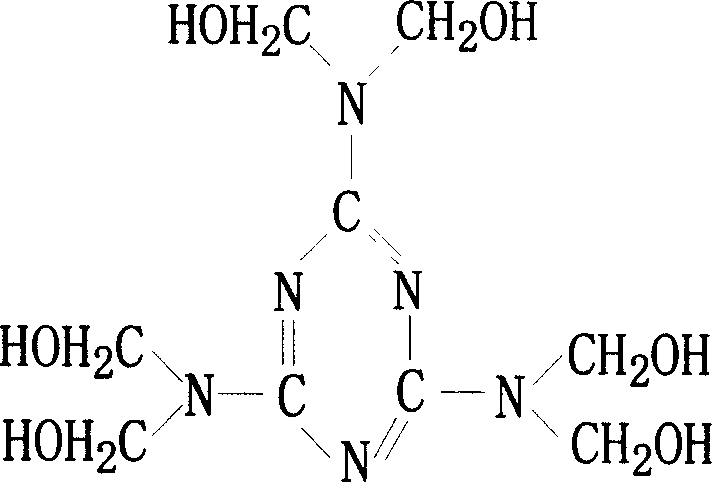

[0027] Cut 20Kg of disperse blue primary dye, 0.4Kg of emulsifier (0.1Kg of fatty alcohol polyoxyethylene ether T07, 0.1Kg of polypyrrolidone, 0.2Kg of sodium lignosulfonate), and 330Kg of water in a high-speed shearing machine for 20-30min , adjust the pH=3~4; pump it into the reaction kettle, add 10Kg of the etherified body of I monomer dropwise at 20°C, and then rais...

Embodiment 2

[0033] A microcapsule disperse black, which is formed by mixing three microcapsule disperse dyes of blue, purple and orange in a mass ratio of 0.75:0.75:1; the blue, violet and orange microcapsule disperse dyes are made of etherified melamine resin. The microcapsule wall material monomer uses blue, purple, and orange disperse primary color dyes as core materials respectively, and adopts in-situ polymerization to prepare blue, purple, and orange microcapsule disperse dyes. The average particle size of the microcapsules is 15-40 μm.

[0034] The preparation method of above-mentioned microcapsule dispersion black is:

[0035] Cut 20Kg of disperse blue primary dye, 0.6Kg of emulsifier (0.4Kg of disodium lauryl sulfosuccinate monoester, 0.2Kg of Pingpingjia), 180Kg of water in a high-speed shearing machine for 30min, and adjust the pH to 3-4; It was pumped into the reaction kettle, and 15Kg of the etherified body of monomer I was added dropwise at 30°C, and then the temperature wa...

Embodiment 3

[0040] A microcapsule disperse black, which is formed by mixing three microcapsule disperse dyes of blue, purple and orange in a mass ratio of 0.60:0.83:1; the blue, violet and orange microcapsule disperse dyes are made of etherified melamine resin. The microcapsule wall material monomer uses blue, purple, and orange disperse primary color dyes as core materials respectively, and adopts in-situ polymerization to prepare blue, purple, and orange microcapsule disperse dyes.

[0041] The preparation method of above-mentioned microcapsule dispersion black is:

[0042] Cut 20Kg of disperse blue dye, 0.5Kg of emulsifier (0.01Kg of sodium carboxymethyl cellulose, 0.29Kg of Pingpingjia, 0.2Kg of maleic acid copolymer), and 288Kg of water in a high-speed shearing machine for 30min, and adjust PH=3 ~4; pump into the reaction kettle, add 12.5Kg of the etherified body of I monomer dropwise at 30°C, and then raise the temperature to 58°C. After the dropwise addition, raise the temperature...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com