Polyphenylene ether resin composition and molded article of same

A technology of resin composition and polyphenylene ether resin, which is applied in the field of polyphenylene ether resin composition, can solve problems such as insufficient weather resistance and reduced electric tracking resistance, and achieve excellent weather resistance, excellent electric tracking resistance, and black high degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

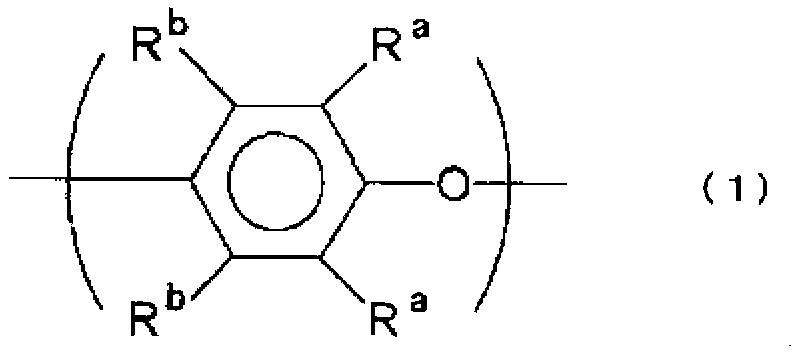

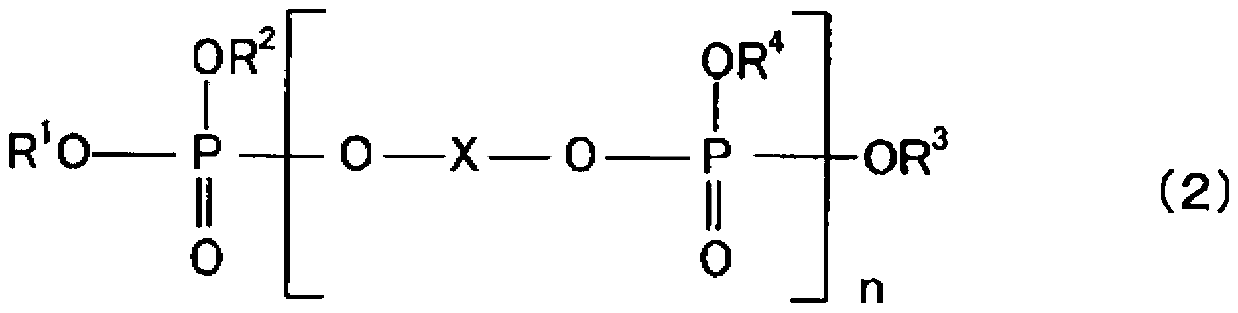

Method used

Image

Examples

Embodiment 1~30、 comparative example 1~10

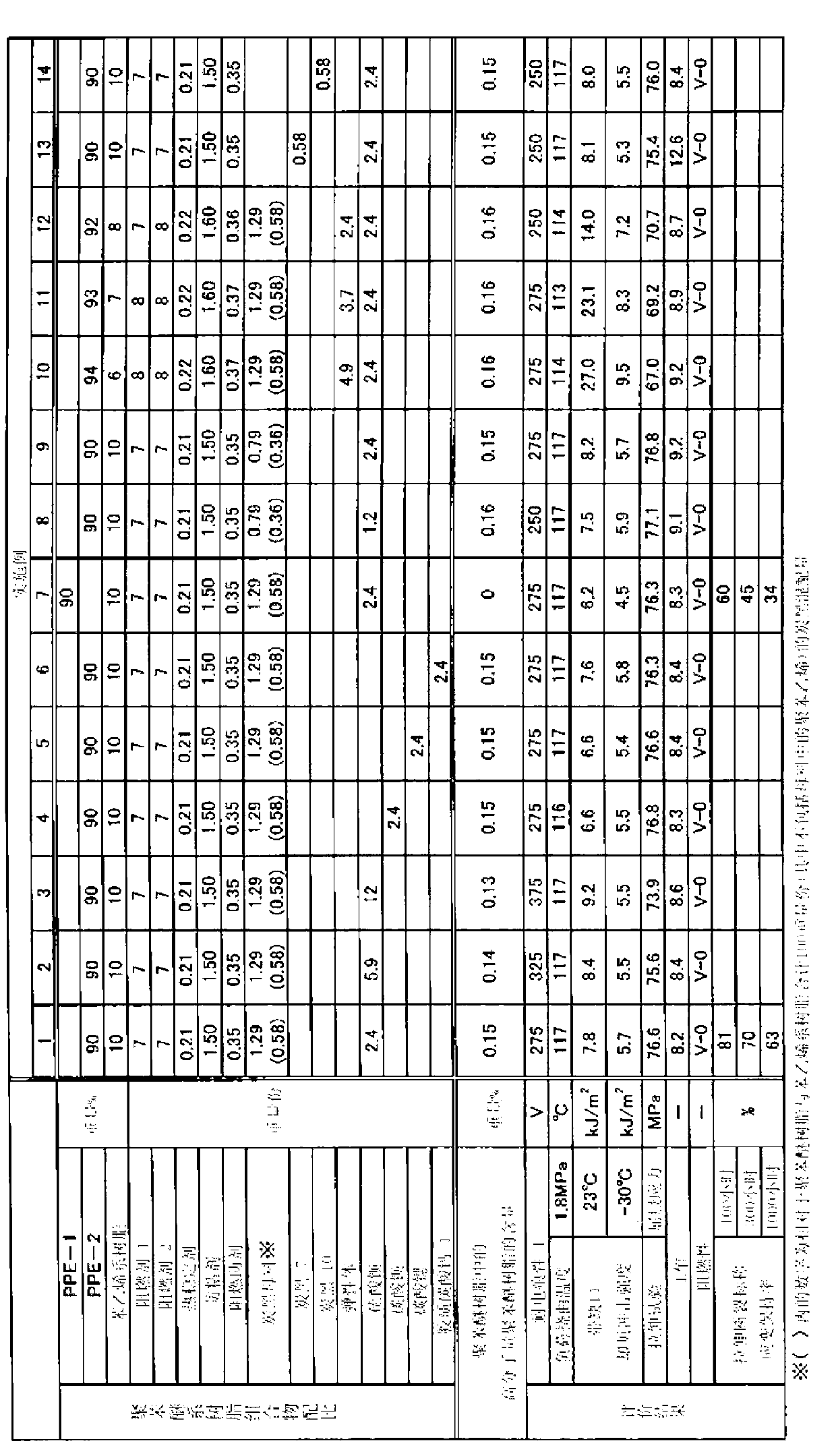

[0264] [Examples 1-30, Comparative Examples 1-10, Reference Example 1]

[0265] The compounding components shown in Tables 1 to 4 were uniformly mixed with a drum mixer in the ratio shown in Tables 1 to 4, and the twin-screw extruder "PCM-30" manufactured by Ikegai Corporation was used. The obtained mixture was melt-kneaded at 280° C. and a rotation speed of 150 rpm, extruded into strands, cooled, cut, and pelletized. In addition, in Tables 1-4, the compounding quantity of the additive other than a polyphenylene ether resin and a styrene-type resin is a compounding quantity with respect to the total 100 weight part of polyphenylene ether resin and a styrene-type resin.

[0266] [Evaluation results]

[0267] The evaluation results are shown in Tables 1-4.

[0268] [Table 1]

[0269]

[0270] [Table 2]

[0271]

[0272] [table 3]

[0273]

[0274] [Table 4]

[0275]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com