Black carbon crushing machine

A pulverizer and carbon black technology, applied in grain processing, dispersed particle separation, chemical instruments and methods, etc., can solve the problems of poor dispersibility and fluidity of carbon black, narrow particle size distribution, etc., and achieve significant economic value, Narrow particle size distribution and good tinting strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

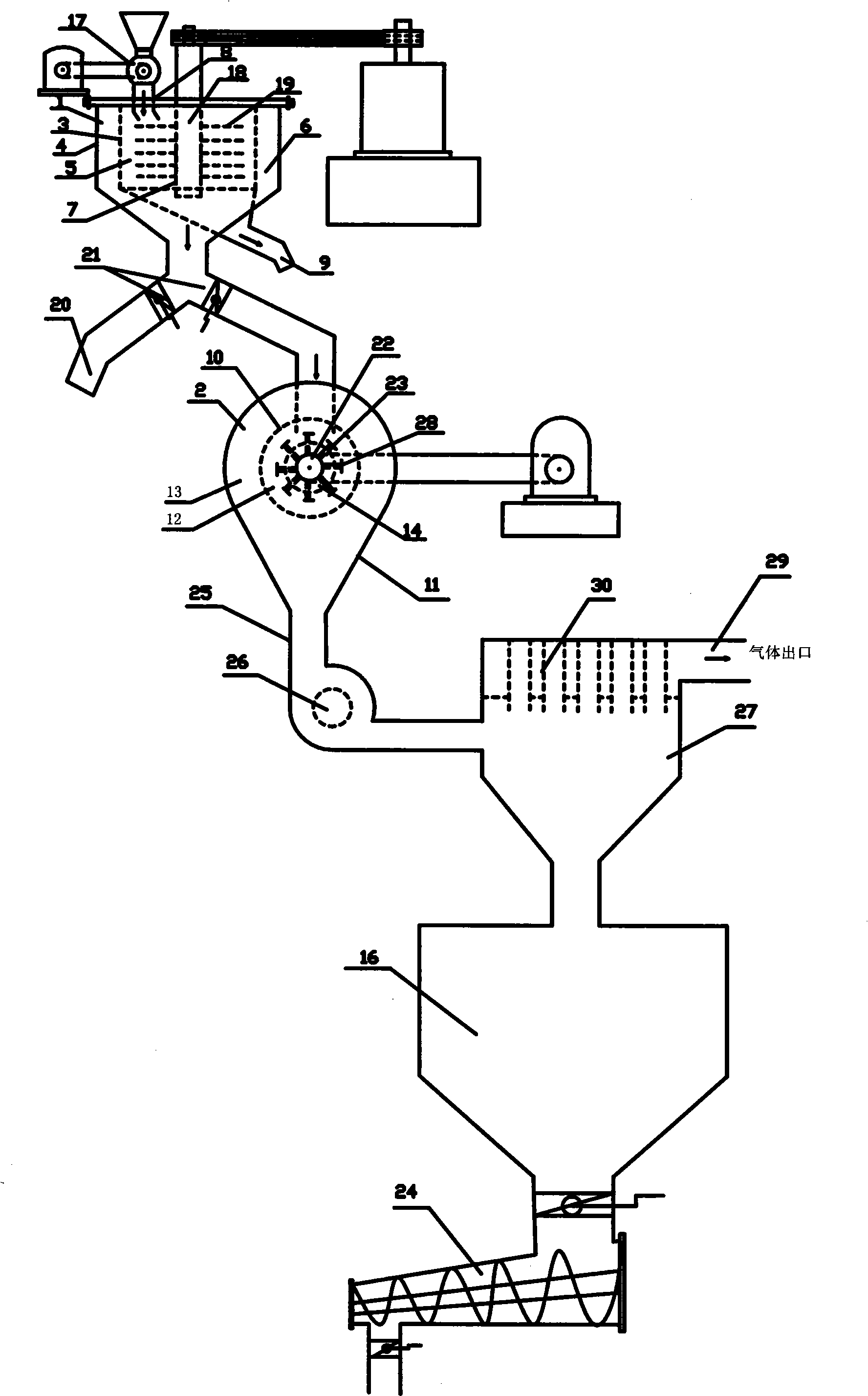

[0009] The carbon black pulverizer of the present invention comprises a frame and a main beating chamber 1 and a secondary beating chamber 2 arranged in sequence on the frame, and the main beating chamber 1 is composed of a vertical main screen 3 and a vertically arranged main screen. Peripheral air-permeable layer 4 is divided into main powder cavity 5 and filter cavity 6, and main powder cavity is provided with crushed powder mixer 7 vertically, and main powder cavity is provided with granular carbon black inlet 8 and powdery carbon black outlet 9 , the outlet of the filter cavity 6 leads to the secondary beating chamber 2; the secondary beating chamber 2 is divided into a secondary main beating chamber 12 by a horizontal secondary main screen 10 and a shell baffle 11 erected on the periphery of the secondary main screen And the secondary filter cavity 13, the secondary powder agitator 14 is horizontally arranged in the secondary main powder cavity, and the secondary main pow...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com