Composite active black dye

A technology of reactive black and dyes, applied in the field of reactive black dyes, to achieve the effects of reducing head and tail color difference, uniform dyeing, lifting power and blackness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

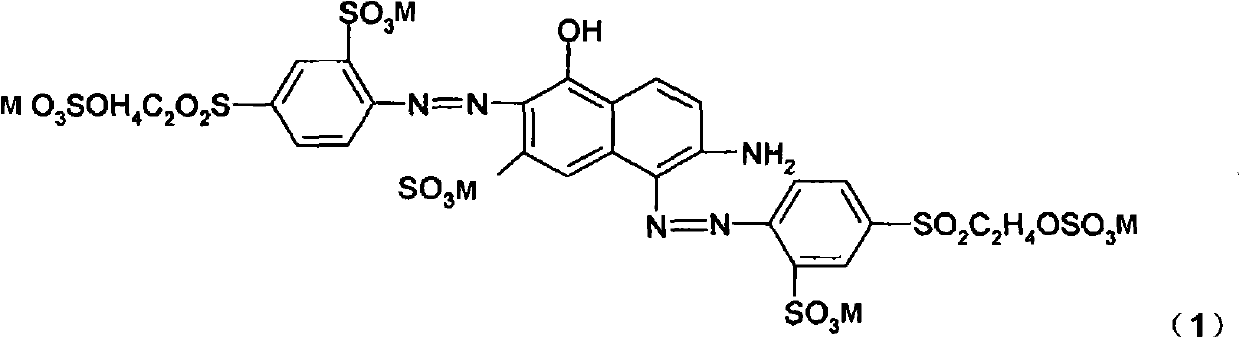

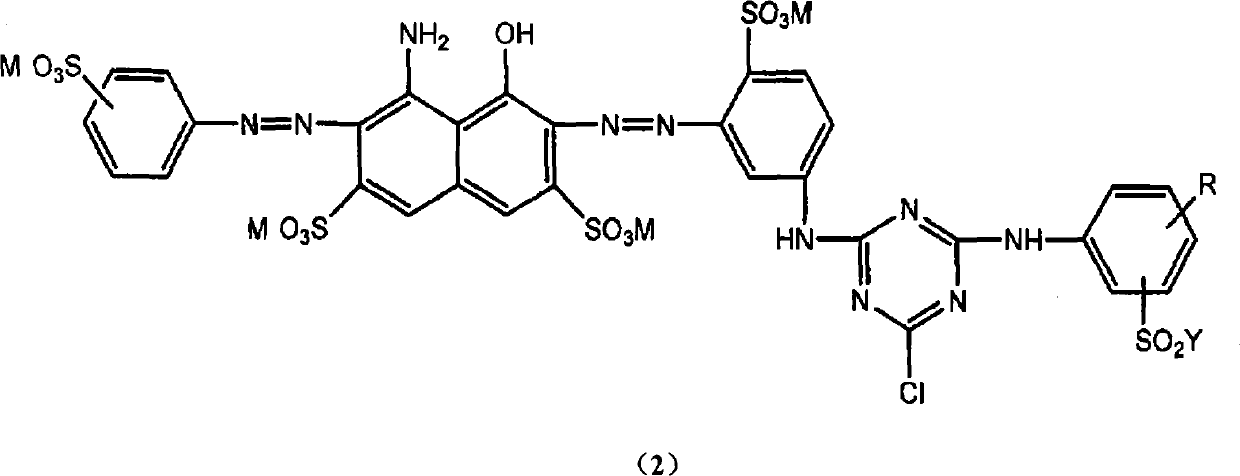

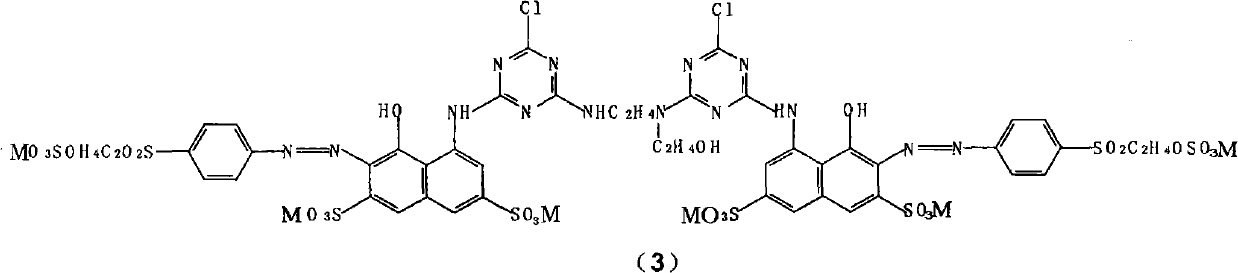

Image

Examples

Embodiment 1

[0040] The dyestuff of the formula (1-1) obtained by synthesis of 60g, the dyestuff of formula (2-1) obtained by synthesis of 15g, the dyestuff of formula (3-1) obtained by synthesis of 8g, 14g sodium sulfate and 3g dispersant MF are carried out Mechanical blending can obtain the reactive black dye composition of the present invention.

[0041] The disperse dye that embodiment 1 is made carries out performance test, and test method is as follows:

[0042] 1 g of the dye composition prepared in the above-mentioned manner was fully dissolved with an appropriate amount of water, and then settled in a 250 ml volumetric flask. Draw 50ml of dye solution and mix it with 50ml of water, then add 5g of cotton cloth and 6g of sodium sulfate, then raise the temperature to 60°C at a rate of 1°C / min, keep it for 30 minutes, add 2g of sodium carbonate, and keep it at 60°C for 30 minutes, then Take out the cotton cloth to be dyed, boil it with non-ionic detergent boiling soap for 15 minutes,...

Embodiment 2-4

[0043] Embodiment 2-4, comparative example 1-3:

[0044] According to the preparation method of Example 1, the consumption is as shown in Table 1

[0045] Table 1

[0046]

[0047] The test results are shown in Table 2:

[0048] Table 2

[0049]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com