Green acid dye composition, green acid dye and preparation method and application thereof

A technology for acid dyes and compositions, applied in the field of dyes, can solve problems such as scarcity, and achieve the effects of simple and easy preparation method, excellent rubbing fastness, and easy acquisition.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

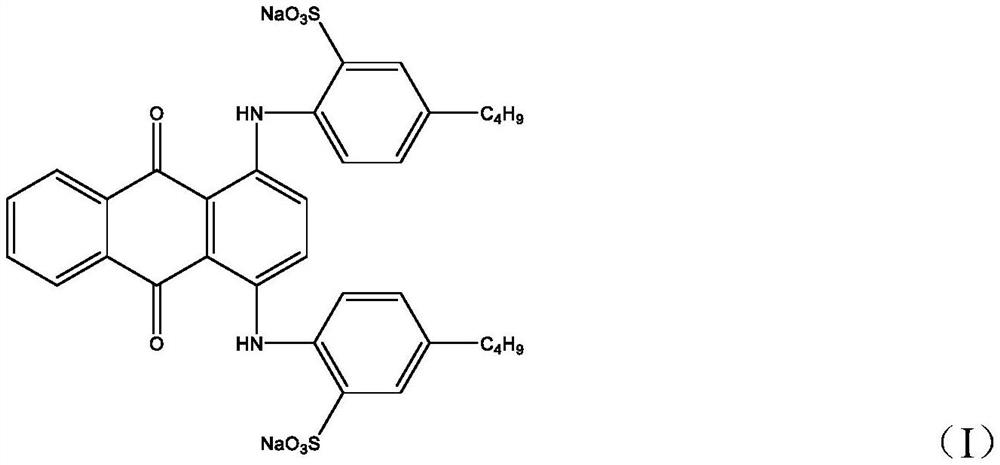

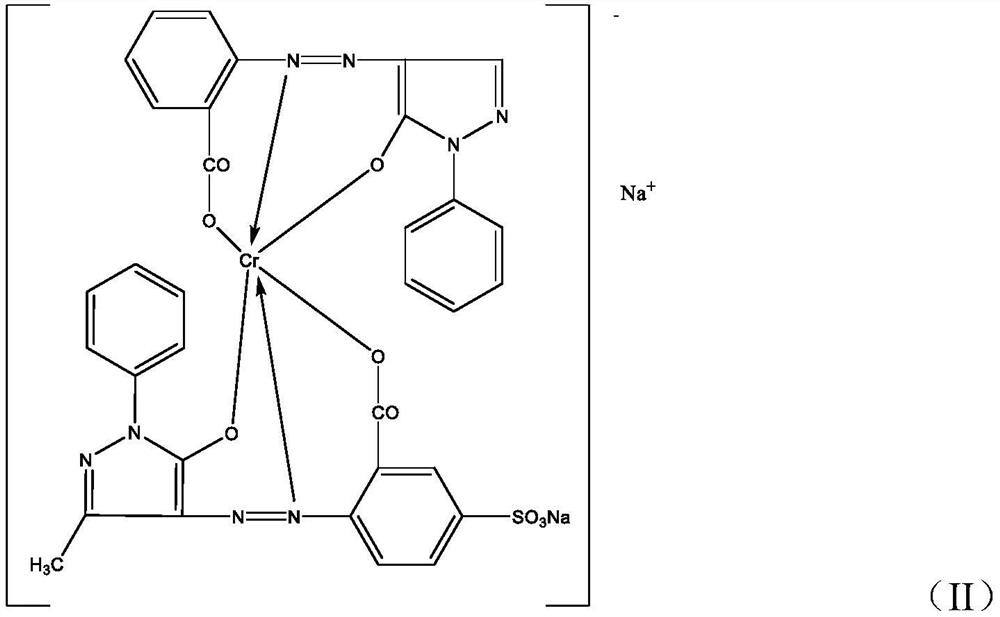

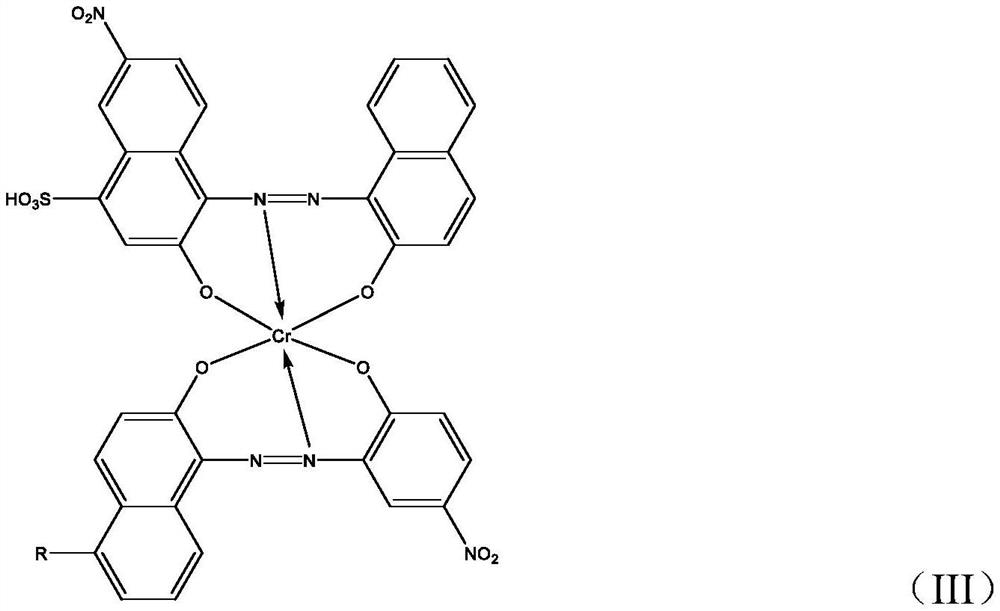

Image

Examples

preparation example Construction

[0055] The present invention also provides a preparation method of the green acid dye according to the present invention, comprising the following steps:

[0056] After mixing the dye components, use a sand mill or a grinder to granulate them in the presence of auxiliary materials; or granulate the dye components with a sand mill or a grinder in the presence of auxiliary materials. After treatment, mixing is performed again.

[0057]Specifically, the method includes: mixing the dye monomer compounds of the green acid dye composition according to the ratio, and using a pulverizer such as a sand mill or a grinder to form particles in the presence of an auxiliary agent; In the presence of auxiliary agents, the dye monomers are separately processed into micronized particles with a pulverizer such as a sand mill or a grinder, and then mixed in the above-mentioned proportions.

[0058] The present invention also provides a use of the green acid dye according to the present inventio...

Embodiment 1~10

[0063] According to the ratio of raw materials shown in Table 1, the dye component A, dye component B, dye component C and auxiliary agents are ground by a pulverizer (grinder) and then mixed into a mixer to obtain a green acid dye.

[0064] Table 1 Units: grams

[0065]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com