Preparation method of regenerative silk protein fiber with skin-core structure

A technology of regenerated silk and skin-core structure is applied in the field of preparation of regenerated silk protein fibers, which can solve the problems such as the regenerated silk protein fibers that have not been seen, and achieve the effects of simple preparation method, extended application scope and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

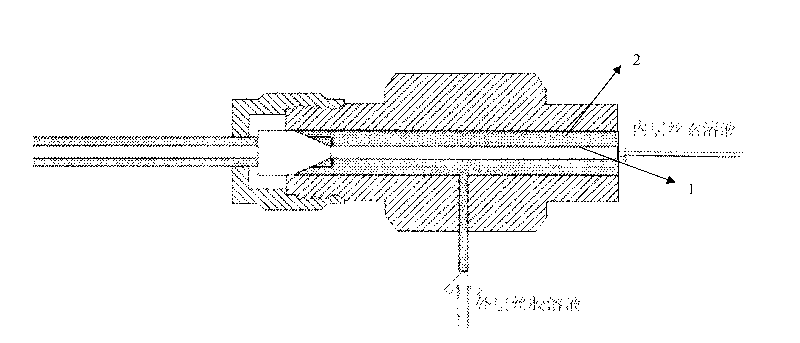

Method used

Image

Examples

Embodiment 1

[0022] (1) the silkworm cocoon is used the Na of mass volume ratio 0.5% 2 CO 3 After the solution is degummed, it is dissolved in a 9.0mol / L LiBr solution, and then centrifugal dialysis is concentrated to a solution with a mass percentage of 20%;

[0023] (2) Sericin powder is dissolved in aqueous solution and is made into the solution that mass percent is 50%;

[0024] (3) The solution obtained in the above step (1) is used as the inner tube spinning solution, and the solution obtained in the step (2) is used as the outer tube spinning solution, which is respectively injected into the inner and outer tubes of the coaxial spinneret, and heated at room temperature. Coaxial electrospinning was carried out under the following parameters: the flow rate of the outer tube solution was 1 μL / min, the flow rate of the inner tube solution was 1 μL / min, the voltage was 30 kV, and the receiving distance was 6 cm.

[0025] The obtained regenerated silk fibroin fiber having a skin-core st...

Embodiment 2

[0028] (1) the silkworm cocoon is used the Na of mass volume ratio 0.5% 2 CO 3 After the solution is degummed, it is dissolved in a 9.0mol / L LiBr solution, and then centrifugal dialysis is concentrated to a solution with a mass percentage of 20%;

[0029] (2) Sericin powder is dissolved in aqueous solution and is made into the solution that mass percent is 70%;

[0030] (3) The solution obtained in the above step (1) is used as the inner tube spinning solution, and the solution obtained in the step (2) is used as the outer tube spinning solution, which is respectively injected into the inner and outer tubes of the coaxial spinneret, and heated at room temperature. Coaxial electrospinning was carried out under the following spinning parameters: the flow rate of the outer tube solution was 4 μL / min, the flow rate of the inner tube solution was 4 μL / min, the voltage was 30 kV, and the receiving distance was 6 cm.

[0031] The obtained regenerated silk fibroin fiber having a ski...

Embodiment 3

[0034] (1) the silkworm cocoon is used the Na of mass volume ratio 0.5% 2 CO 3 After the solution is degummed, it is dissolved in a 9.0mol / L LiBr solution, and then concentrated to a solution with a mass percentage of 35% by centrifugal dialysis;

[0035] (2) Sericin powder is dissolved in aqueous solution and is made into the solution that mass percent is 70%;

[0036] (3) The solution obtained in the above step (1) is used as the inner tube spinning solution, and the solution obtained in the step (2) is used as the outer tube spinning solution, which is respectively injected into the inner and outer tubes of the coaxial spinneret, and heated at room temperature. The coaxial electrospinning was carried out under the following spinning parameters: the flow rate of the outer tube solution was 10 μL / min, the flow rate of the inner tube solution was 20 μL / min, the voltage was 50 kV, and the receiving distance was 10 cm.

[0037] The obtained regenerated silk fibroin fiber havin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com