Black and active dye

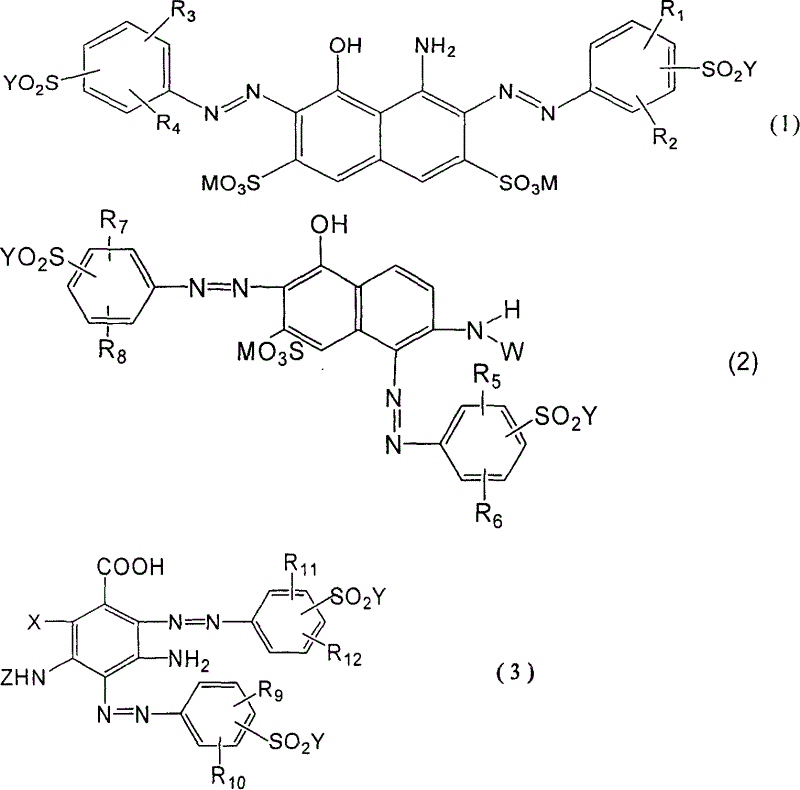

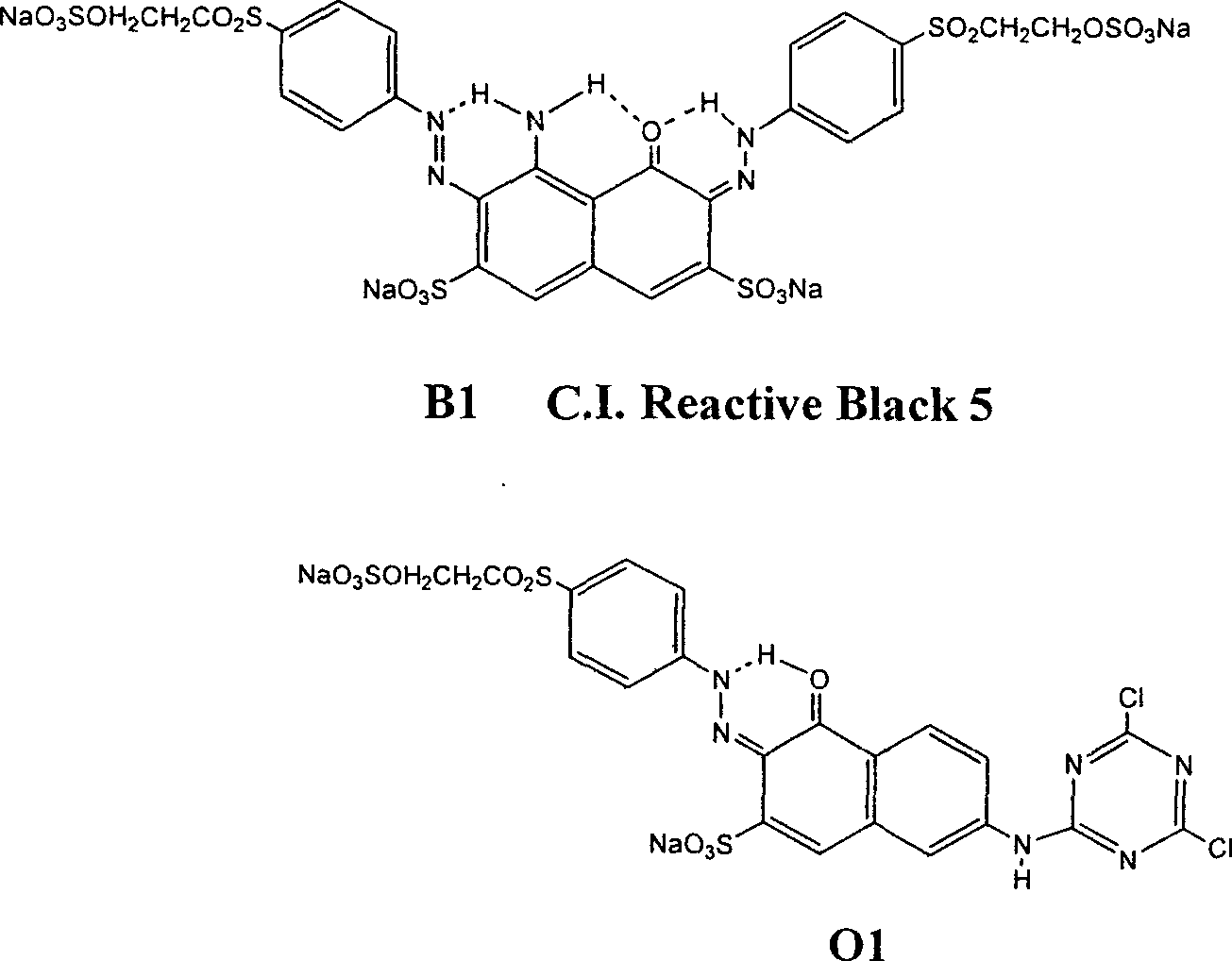

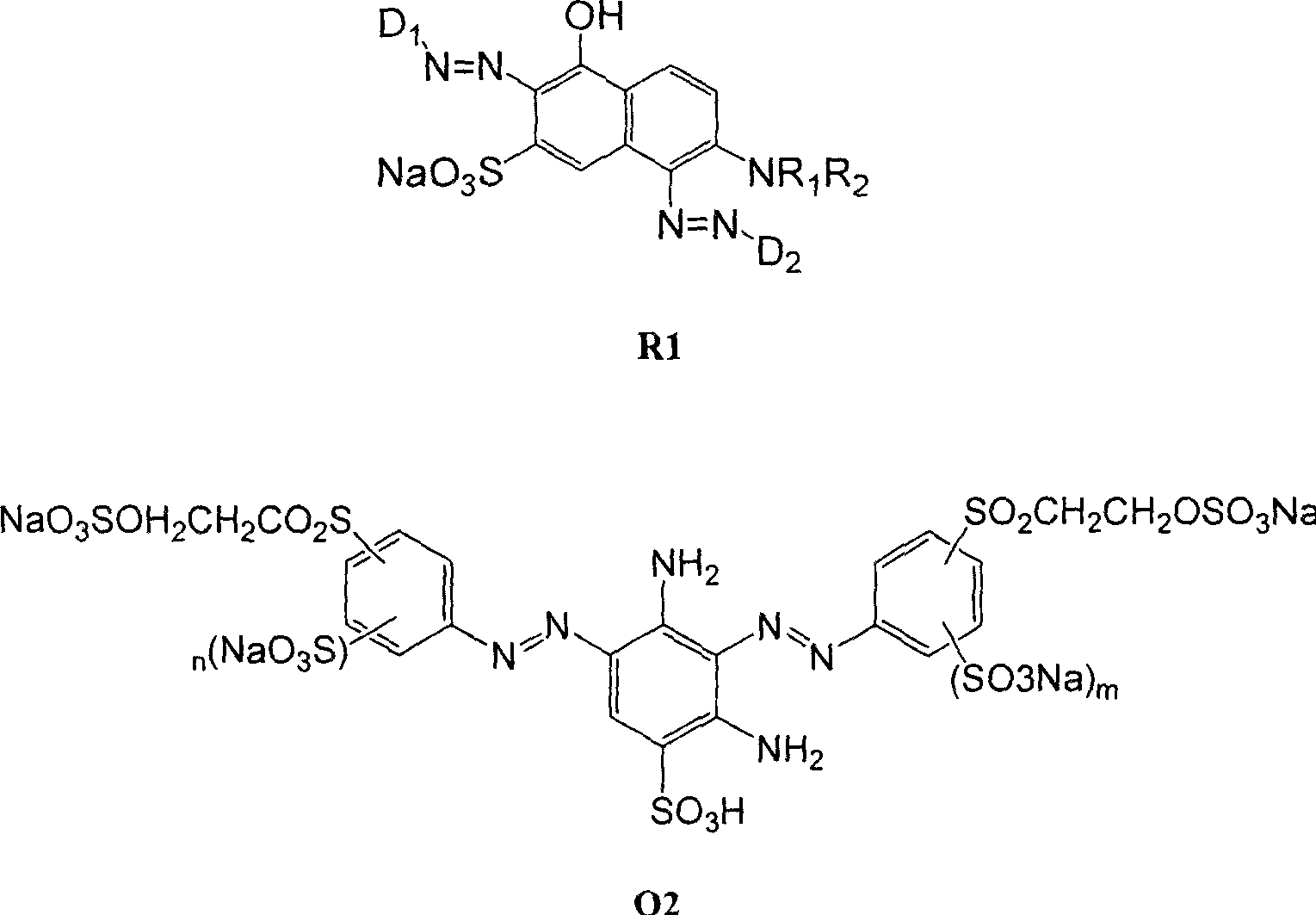

A reactive dye and black technology, which is applied to the composition and synthesis process of deep black reactive dyes, can solve the problems of not reaching the degree of deep black, large difference in fiber affinity, color pattern, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] Synthesis of sodium hydroxymethanesulfonate:

[0065]

[0066] Dissolve 104g of sodium bisulfite (1mol) in 150ml of water in a 500ml three-necked flask, add 88g of 36% formaldehyde solution (1.05mol) dropwise at 35°C, and stir the reaction below 50°C for 3-5 hours. Dehydrate 100ml under reduced pressure at 60-70°C to obtain a concentrated solution. Cool the concentrated solution, add a certain amount of crystallization solvent, stand at 0-5°C for 5 hours to crystallize, filter, wash the filter cake with 30ml of absolute ethanol, and dry to obtain 125g of sodium hydroxymethanesulfonate as a white solid.

Embodiment 2

[0068] Synthesis of sulfomethylated J acids:

[0069]

[0070] Disperse 23.9g of J acid in 200ml of water in a 500ml three-necked bottle, and use 20% Na 2 CO 3 Adjust the pH of the solution to 6-7, add 15g of sodium hydroxymethanesulfonate, and react for 3-6h below 50°C to obtain a sulfomethylated J acid solution, wherein the content of sulfomethylated J acid in the organic matter is ≥95% ( HPLC).

Embodiment 3

[0072] Synthesis of red dye 201:

[0073] Mix 56.2g of para-ester and 13g of sulfuric acid, add 350g of ice-water mixture, beat for 30min, add 47g of 30% NaNO dropwise at 0-5°C 2 Solution, NaNO during dropwise addition and reaction 2 excess. After the dropwise addition, continue to stir the reaction for 2h, the excess NaNO 2 Destroy it with sulfamic acid to obtain the para-ester diazonium salt.

[0074] Add the para-ester diazonium salt to the sulfomethylated J acid solution of Example 2, control the pH ≤ 2 at 0-5°C, and perform the coupling reaction for 3 hours, then adjust the pH to 5-6, and perform the coupling reaction for 3 hours. Concentrate the resulting dye solution, fry it to dryness, and pulverize it to obtain 125 g of dye powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com