Water-collecting polymer filament imitating spider silk structure and preparation method thereof

A technology of polymer silk and imitation spider silk, which is applied in the field of bionic water collection fiber and its preparation, can solve the problems of high water collection cost, inability to meet water demand, low water collection efficiency, etc., and achieve high collection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Embodiment 1. has the preparation of the water-collecting fiber of the imitation spider silk structure of PMMA spindle knot

[0047] (1) preparation contains the mass fraction of ultraviolet stabilizer two (2,2,6,6-tetramethylpiperidinyl) sebacate as the mixed solution of the DMF of 3% PMMA and water, wherein ultraviolet stabilizer bis (2,2,6,6-tetramethylpiperidinyl) the massfraction of sebacate in the DMF of PMMA and the mixed solution of water is 0.8wt%, the water in the DMF of PMMA and the mixed solution of water The mass fraction is 0.5wt%, and the balance is DMF;

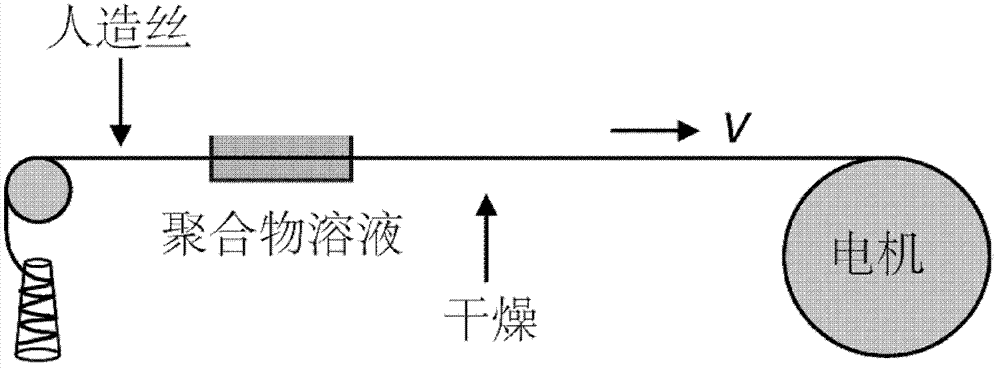

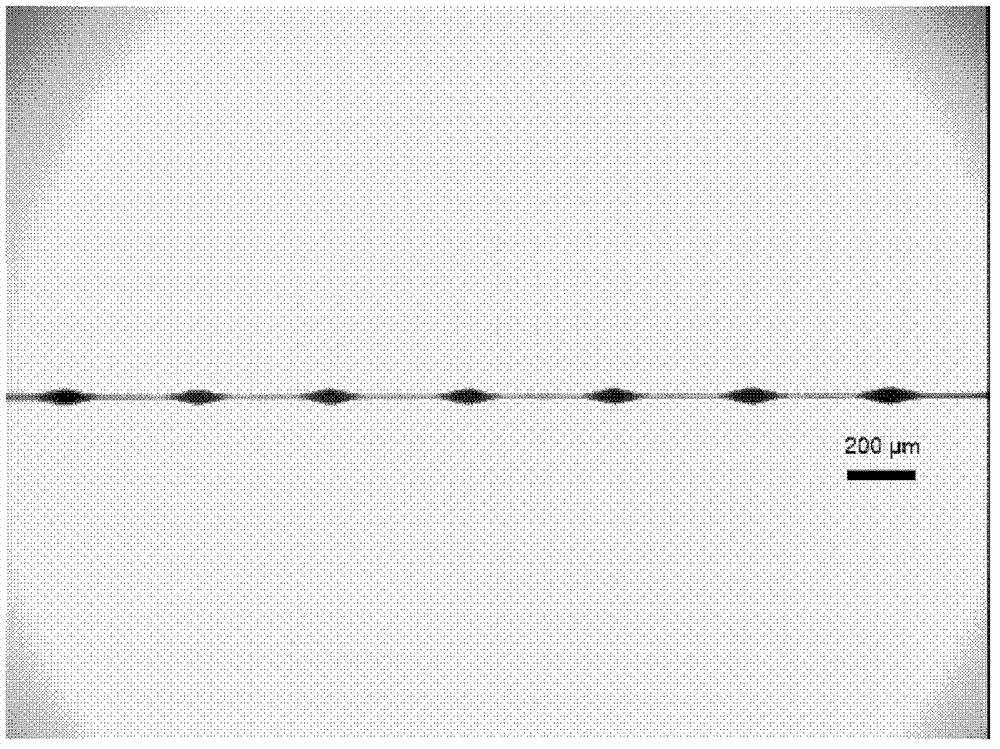

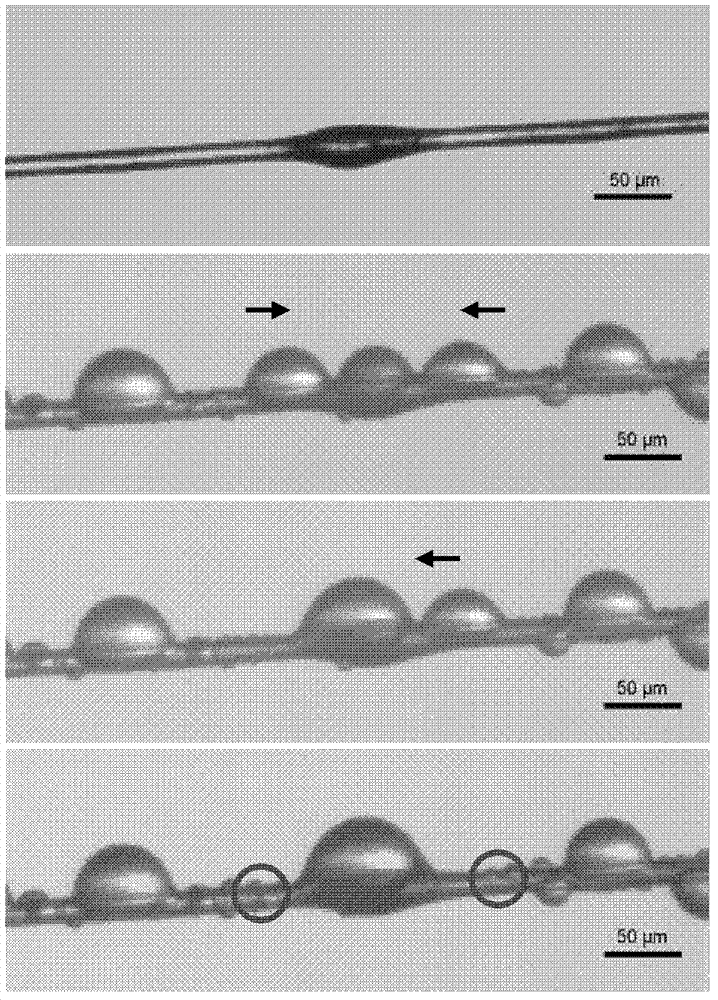

[0048] (2) The man-made nylon fiber that is 10 μm in diameter is completely submerged into the mass fraction containing ultraviolet stabilizer bis(2,2,6,6-tetramethylpiperidinyl) sebacate obtained in step (1) is 3 In the mixed solution of DMF and water of PMMA, adjust the rotation speed of the motor connected to one end of the nylon fiber, so that the nylon fiber can be leveled from the above mixed sol...

Embodiment 2

[0052] Example 2. Preparation of water-collecting fibers with PS spindle knots imitating spider silk structure

[0053] (1) preparation contains the massfraction of antioxidant 2,6-di-tert-butyl-4-methylphenol as the mixed solution of DMAc and ethanol of 15% PS, wherein antioxidant 2,6-di-tert-butyl-4 -The addition of methylphenol is 1.2% of the weight of the mixed solution of DMAc and ethanol of PS, the mass fraction of ethanol in the mixed solution of DMAc and ethanol of PS is 3wt%, and the balance is DMAc;

[0054] (2) the man-made polypropylene fiber that is 1000 μ m is immersed in the DMAc and ethanol that the massfraction of the PS that contains antioxidant 2,6-di-tert-butyl-4-methylphenol that the diameter is 1000 μm is completely immersed in step (1) In the mixed solution, adjust the rotational speed of the motor connected to one end of the polypropylene fiber, so that the polypropylene fiber is pulled out horizontally from the above mixed solution at a uniform speed a...

Embodiment 3

[0058] Example 3. Preparation of water-collecting fibers with PVDF spindle knots imitating spider silk structure

[0059] (1) preparation contains antioxidant 2,6-di-tert-butyl-4-methylphenol, and the mass fraction of ultraviolet absorber 2-cyano-3,3-diphenylacrylate 2-ethylhexyl is 9% A mixed solution of THF and acetone of PVDF, wherein the addition of antioxidant 2,6-di-tert-butyl-4-methylphenol is 0.8% of the weight of the mixed solution of THF and acetone of PVDF, and the ultraviolet absorber 2-cyanide The addition of 2-ethylhexyl-3,3-diphenylacrylate is 0.2% of the mixed solution weight of THF and acetone of PVDF, and the mass fraction of acetone in the mixed solution of THF and acetone of PVDF is 1.5wt %, the balance is THF;

[0060] (2) The man-made spandex fibers with a diameter of 200 μm are completely submerged into the obtained step (1) containing antioxidant 2,6-di-tert-butyl-4-methylphenol, ultraviolet absorber 2-cyano-3,3- The mass fraction of 2-ethylhexyl diph...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com