Preparation method of composite nanometer fiber small-diameter intravascular tissue engineering stent material

A technology of composite nanofibers and vascular tissue, used in stents, medical science, prostheses, etc., can solve problems such as the inability to simulate the structure and function of the extracellular matrix, the difficulty of determining the elasticity and compliance of the construct, and the residual stent. Achieving good biocompatibility and anticoagulant properties, favorable adhesion and growth, good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

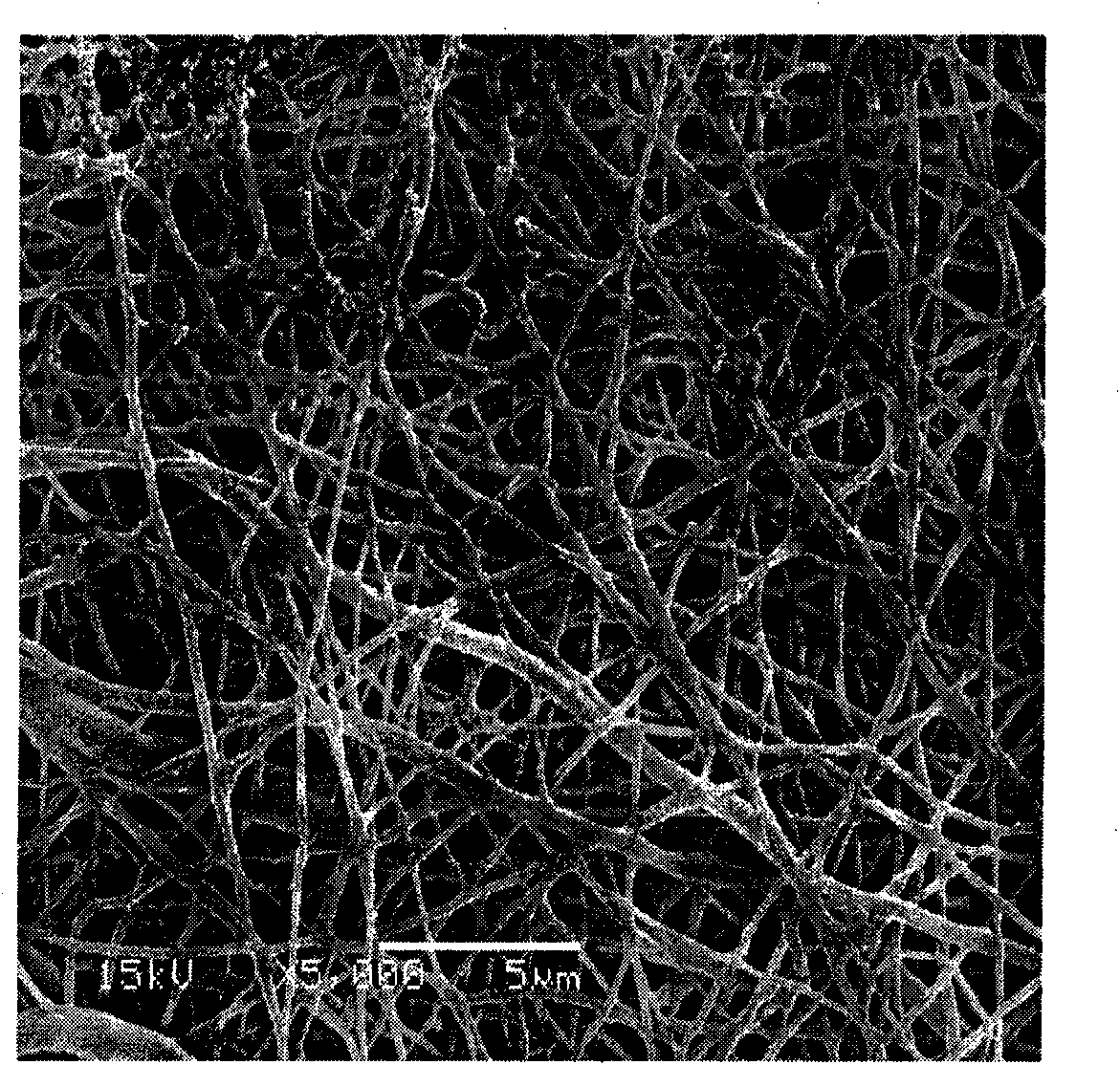

[0028] 1. Preparation of electrospinning solution: Weigh and dissolve 0.1g pNSR16, 0.8gPCL and 0.1gCS in 5ml of 88% formic acid to obtain 20% (w / v) pNSR32 / PCL / CS mixed electrospinning solution.

[0029] 2. Shaft treatment: Coat a thin layer of polyethylene glycol (PEG) on the stainless steel shaft.

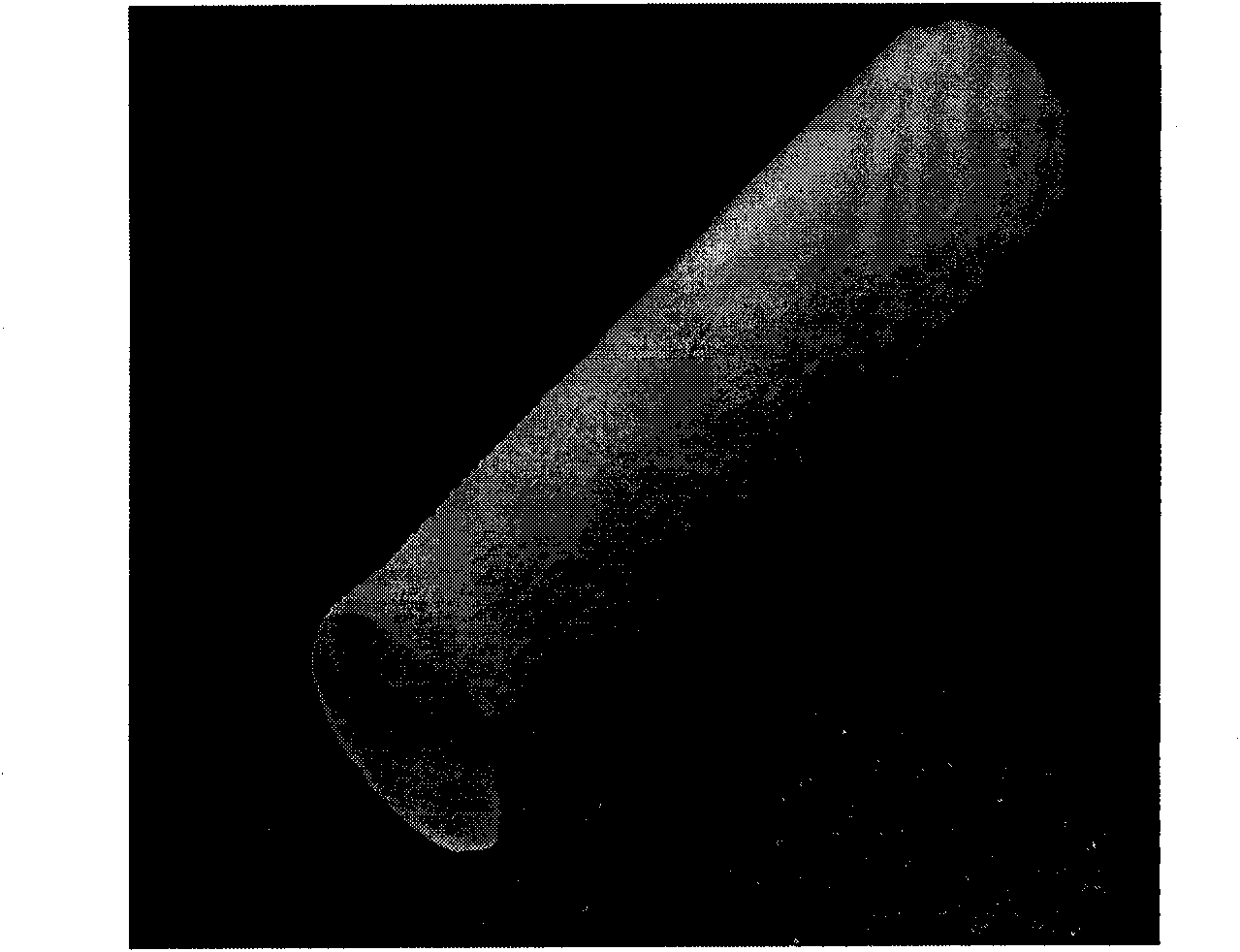

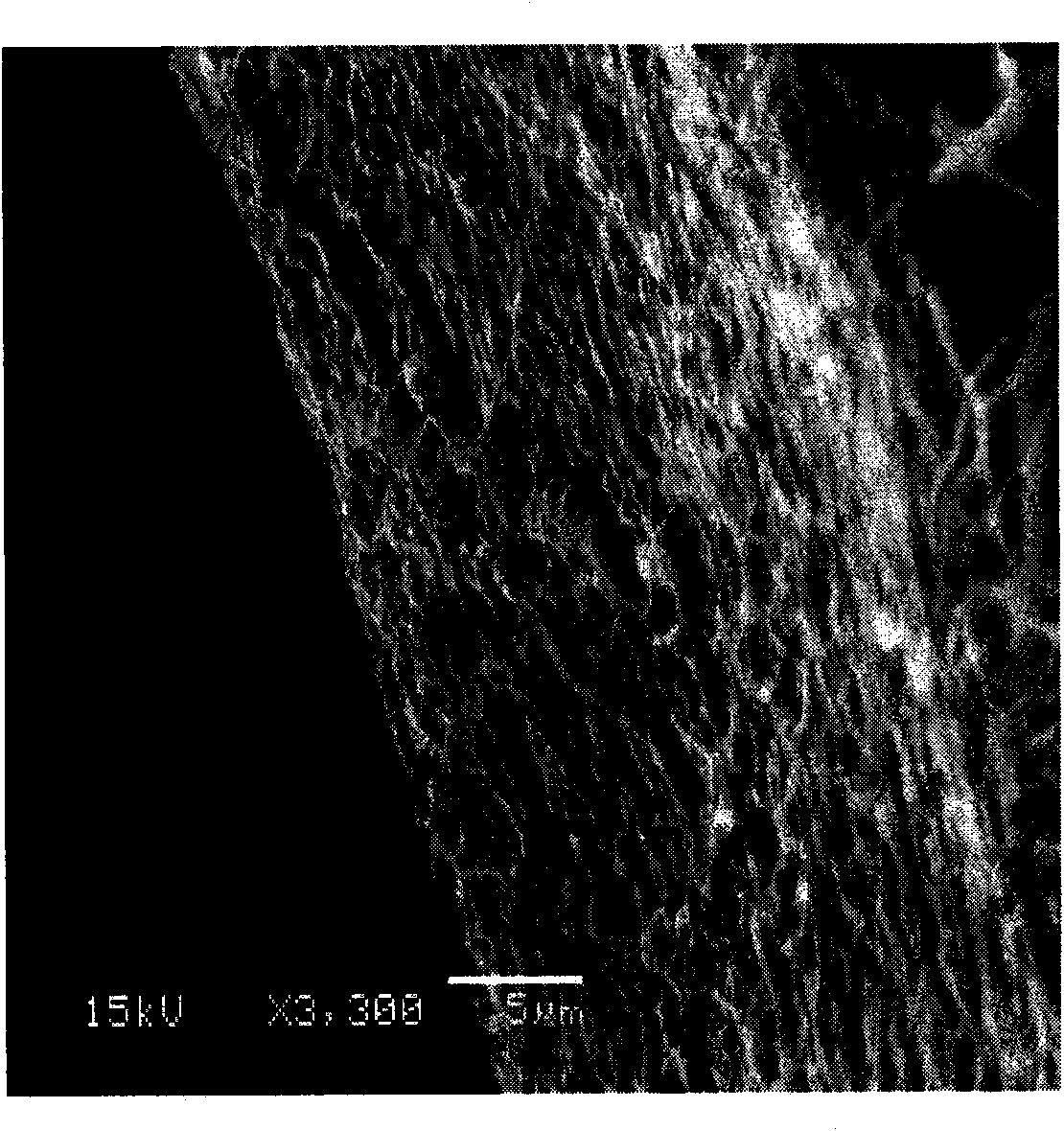

[0030] 3. Preparation of small-diameter vascular stent: draw 1.5ml of spinning solution into a 2ml syringe, place the syringe on the syringe pump, use a cylindrical shaft collector with a cross-sectional diameter of 4mm at a speed of 1000r / min Under the conditions of rotation, curing distance of 18cm, voltage of 80kV, extrusion speed of 5ml / h, and temperature of 45°C, a pNSR32 / PCL / CS composite nanofiber small diameter vascular stent with an inner diameter of 4mm was prepared.

[0031] 4. Post-processing of stent preparation: After rinsing the stent with PBS, immersing in 70% alcohol for 20 minutes, sterile water for 3 minutes and sterile PBS for 5 minutes, the residual polyethylene glyco...

Embodiment 2

[0033] 1. Electrospinning solution preparation: Weigh and dissolve 0.15g pNSR32, 1.2gPCL and 0.15gCS in 5ml 98% formic acid to obtain 30% (w / v) pNSR32 / PCL / CS mixed electrospinning solution.

[0034] 2. Shaft treatment: Coat a thin layer of polyethylene glycol (PEG) on the stainless steel shaft.

[0035] 3. Preparation of small-diameter vascular stent: Draw 2.0ml of spinning solution into a 2.5ml syringe, place the syringe on the syringe pump, and use a cylindrical shaft collector with a cross-sectional diameter of 6mm, with a speed of 1500r / min Under the conditions of speed rotation, curing distance of 20cm, voltage of 100kV, extrusion speed of 7ml / h, and temperature of 50℃, a pNSR32 / PCL / CS composite nanofiber small diameter vascular stent with an inner diameter of 6mm was prepared.

[0036] 4. Post-processing of stent preparation: After rinsing the stent with PBS, immersing in 70% alcohol for 20 minutes, sterile water for 3 minutes and sterile PBS for 5 minutes, the residual polyeth...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com