Technology and method for preparing solution used for preparing graphene in liquid phase

A preparation process, graphene technology, applied in graphene, nanotechnology for materials and surface science, nanotechnology and other directions, can solve the problems of high temperature and pressure control requirements, complex process, difficult to control conditions, etc., to meet the safety requirements. It has the advantages of high stability and green environmental protection, simple preparation process and method, and low manufacturing cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

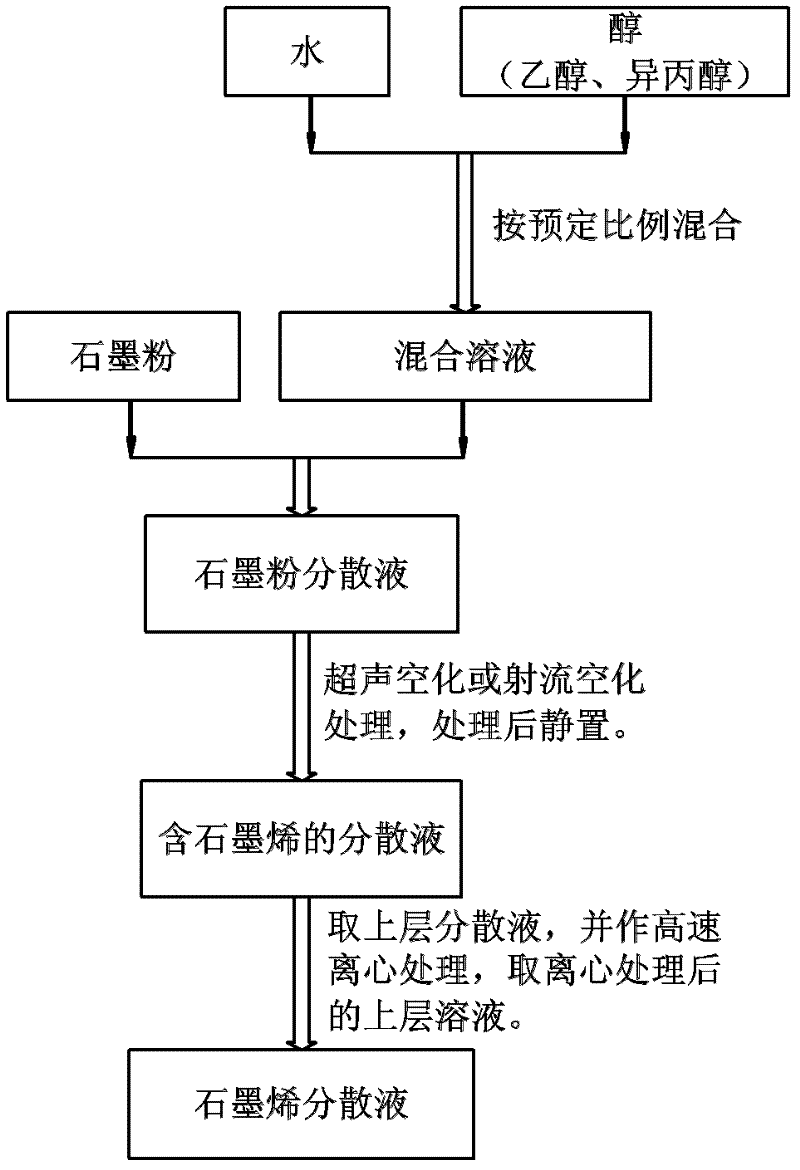

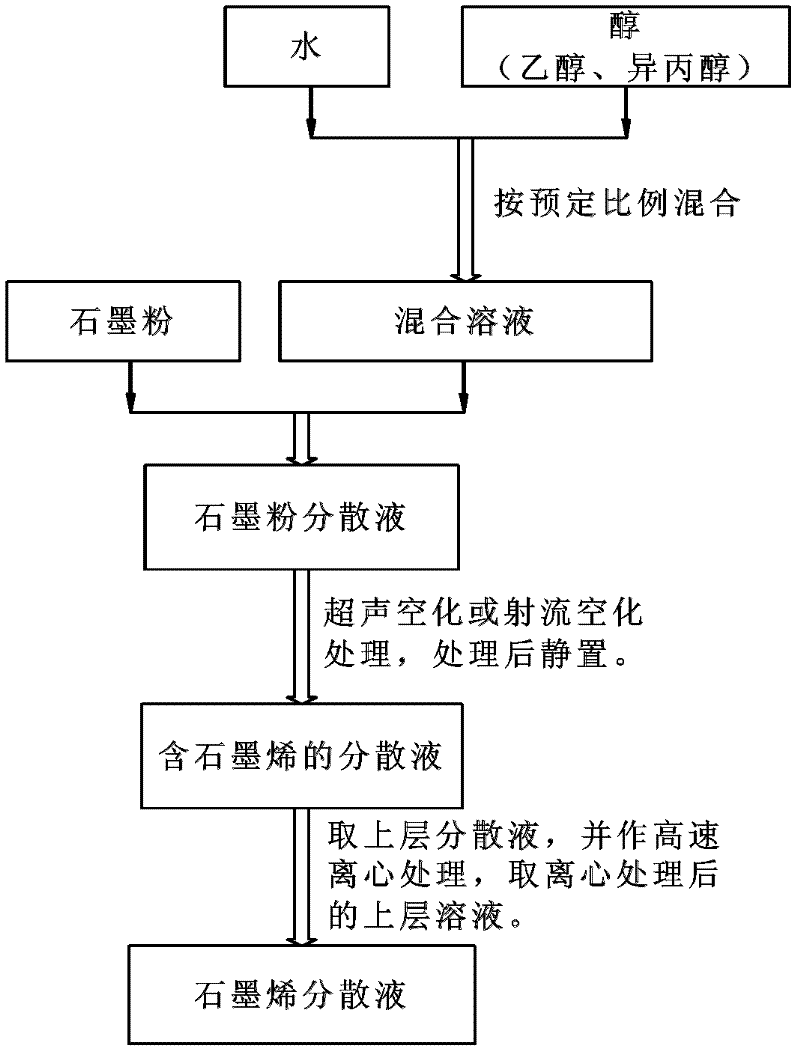

[0030] Embodiment 1, taking the preparation of graphene by ultrasonic cavitation in water and ethanol mixed solution as an example, the detailed process steps are as follows:

[0031] Step 1: Configure 20mL of a mixed solution of water and ethanol, the mass ratio of ethanol is 40%, and the rest is water;

[0032] Step 2: Disperse 4 mg of graphite powder less than 100 microns in it to obtain a graphite dispersion of 0.2 mg / mL, and put it into a 30 mL container bottle;

[0033] Step 3: Place the above-mentioned container bottle containing graphite dispersion in a 1000mL ultrasonic container filled with water, perform ultrasonic treatment for 180min, ultrasonic output power 20W, frequency 40KHz;

[0034] Step 4: Leave the container bottle (containing the graphite dispersion) after ultrasonic treatment for 8 hours, and then take out the upper dispersion;

[0035] Step 5: Put the upper layer dispersion taken out into a centrifuge tube, and then perform high-speed centrifugation at...

Embodiment 2

[0038] Embodiment 2, it is an embodiment to prepare graphene by ultrasonic cavitation in a mixed solution of water and isopropanol, and the detailed process steps are as follows:

[0039] Step 1: Prepare 20 mL of a mixed solution of water and isopropanol, the mass ratio of isopropanol is 55%, and the rest is water;

[0040] Step 2: Disperse 4 mg of graphite powder less than 100 microns in it to obtain a graphite dispersion of 0.2 mg / mL, and put it into a 30 mL container bottle;

[0041] Step 3: Place the above-mentioned container bottle containing the graphite dispersion in a 1000mL ultrasonic container filled with water, perform ultrasonic treatment for 180min, ultrasonic output power 20W, frequency 40KHz;

[0042] Step 4: Leave the container bottle (containing the graphite dispersion) after ultrasonic treatment for 8 hours, and then take out the upper dispersion;

[0043] Step 5: Put the upper dispersion liquid taken out into a centrifuge tube, and then perform high-speed c...

Embodiment 3

[0046] Embodiment 3, taking the preparation of graphene by jet cavitation in water and ethanol mixed solution as an example, the detailed process steps are as follows:

[0047] Step 1: Configure 5000mL of mixed solution of water and ethanol, the mass fraction of ethanol is 40%, and the rest is water;

[0048] Step 2: Disperse 1000 mg of graphite powder less than 100 microns in it to obtain a graphite dispersion of 0.2 mg / mL, and put it into a 10 L storage tank of a jet cavitation device;

[0049] Step 3: Set the working pressure of the plunger pump of the jet cavitation device to 20MPa, the power of the plunger pump motor to 30KW, and the system to run for 30 minutes;

[0050] Step 4: Take out the solution from the storage tank, pour it into a beaker and let it stand for 8 hours, then take out the upper dispersion;

[0051]Step 5: Put the taken out upper layer dispersion liquid into a centrifuge tube, then perform high-speed centrifugation treatment, the centrifuge speed is 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com