Model testing method for adjustment of ore-coke ratio distribution in blast furnace

A model test, ore-coke ratio technology, applied in blast furnaces, blast furnace details, furnace types, etc., can solve the problems of not reflecting the distribution of ore and coke, coke, ore, etc., to save test materials and test charges, accurate measurement , the effect of improving the operating indicators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described through the embodiments below in conjunction with the accompanying drawings.

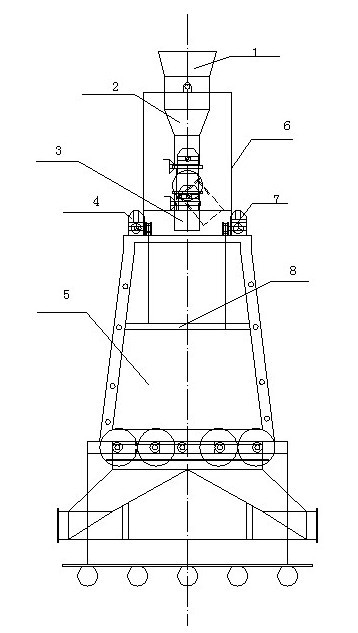

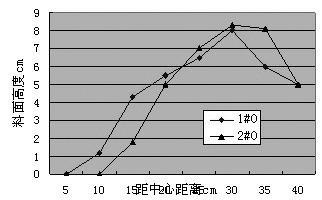

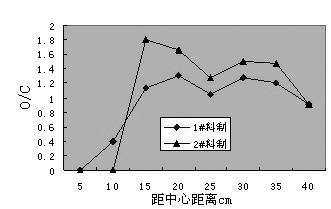

[0022] Pass 2000m in the test room 3 The blast furnace distribution model of the blast furnace scaled down by 10 times simulates the distribution of two typical material systems of Example 1 and Example 2, and analyzes the radial mineral coke ratio distribution of the two material systems.

[0023] First, the preparation of the test charge is carried out.

[0024] The particle size composition of sinter, coke and pellets used in the production site is shown in Table 1, Table 2 and Table 3, and the particle size composition of lump ore is the same as that of sinter. According to the third theorem of similarity, the burden preparation work for the model test is carried out. Since the blast furnace charge is all irregular particles, the charge for the model test should also be reduced by 10 times according to the similarity theorem and the blast f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com