Turbulence method for preparing high-quality graphene

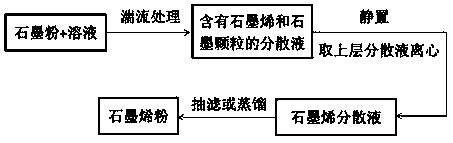

A graphene, high-quality technology, applied in the turbulent flow of the preparation of high-quality graphene, the use of turbulent flow in the field of graphene preparation in solution, can solve the problems of affecting the electrical properties of graphene performance, limiting the quality of graphene, and large graphene defects. , to achieve the effect of less defects, easy scale and uniform thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

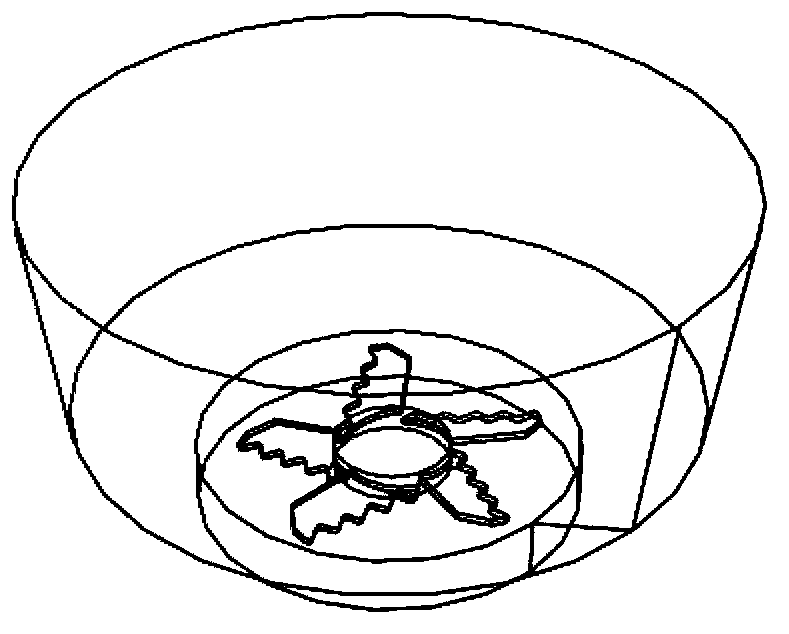

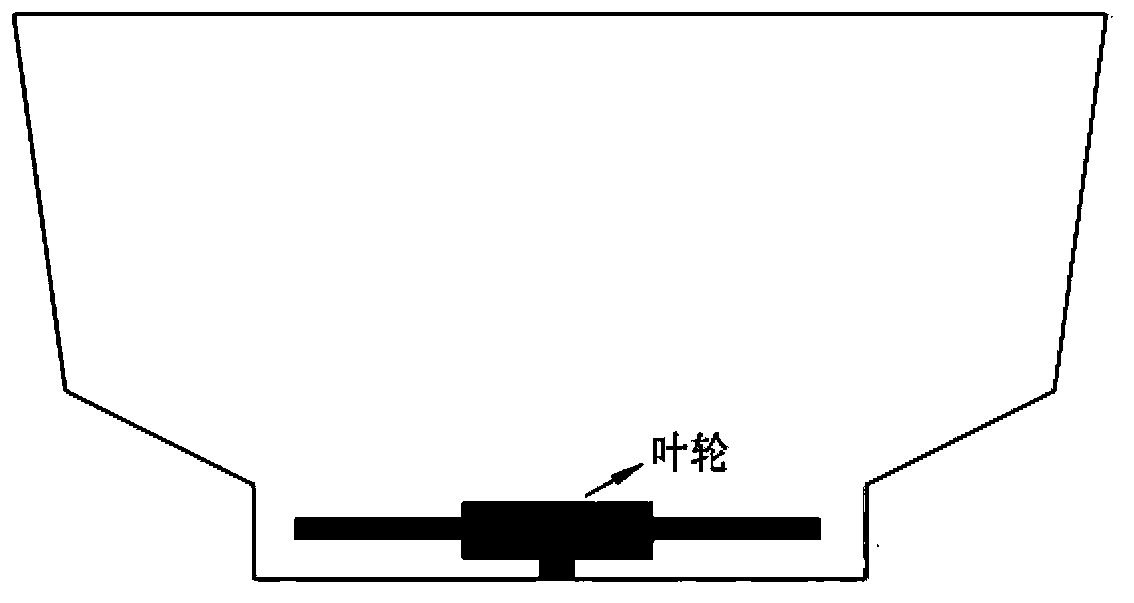

[0030] Embodiment 1, in N-dimethylformamide solvent, stirring produces turbulent flow to peel off flake graphite and prepares high-quality graphene as embodiment, is used to produce the stirring device of turbulent flow such as Figure 2a , Figure 2b As shown, the detailed process steps are as follows:

[0031] Step 1: take flake graphite powder 1200mg, be dispersed in 400mL N-dimethylformamide solvent, obtain the graphite dispersion of 3mg / mL;

[0032] Step 2: Transfer the prepared graphite dispersion to a stirring container, the stirring speed is 5000rpm, and the corresponding Reynolds number is 2×10 6 , to obtain turbulent flow;

[0033] Step 3: process graphite dispersion liquid 1h with turbulence;

[0034] Step 4: Leave the dispersion liquid after turbulence treatment for 1 hour, then take out the upper layer dispersion liquid;

[0035] Step 5: the supernatant liquid that takes out is packed in the centrifuge tube, then with the centrifugal processing 45min of the ce...

Embodiment 2

[0038] Embodiment 2, with in the mixed solution of water and acetone, stirring produces turbulent flow and exfoliates flake graphite and prepares high-quality graphene as embodiment, is used to produce the stirring device of turbulent flow such as Figure 2a , Figure 2b As shown, the detailed process steps are as follows:

[0039] Step 1: Configure 400mL of a mixed solution of water and acetone, the mass fraction of acetone is 75%, and the rest is deionized water, disperse 1200mg flake graphite powder in it to obtain a 3mg / mL graphite dispersion, and put it into a stirring container Inside;

[0040] Step 2: The stirring speed is 5000rpm, and the corresponding Reynolds number is 2×10 6 , to obtain turbulent flow;

[0041] Step 3: Treat the graphite dispersion with turbulent flow for 2 hours;

[0042] Step 4: Leave the dispersion liquid after turbulence treatment for 1 hour, then take out the upper layer dispersion liquid;

[0043] Step 5: the supernatant dispersion liquid...

Embodiment 3

[0045] Embodiment 3, in N-methylpyrrolidone, stirring produces turbulent flow to exfoliate expandable graphite and prepares high-quality graphene as an example, and the stirring device used to generate turbulent flow is as Figure 2a , Figure 2b As shown, the detailed process steps are as follows:

[0046] Step 1: take expandable graphite powder 1200mg, be dispersed in 400mL N-methylpyrrolidone solvent, obtain the graphite dispersion of 3mg / mL;

[0047] Step 2: Transfer the prepared graphite dispersion to a stirring container, the stirring speed is 5000rpm, and the corresponding Reynolds number is 2×106 , to obtain turbulent flow;

[0048] Step 3: Treat the graphite dispersion with turbulent flow for 0.5h;

[0049] Step 4: Leave the dispersion liquid after turbulence treatment for 1 hour, then take out the upper layer dispersion liquid;

[0050] Step 5: the supernatant dispersion liquid that takes out is packed in the centrifuge tube, then with the centrifugal processing 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com