Device and method for large-size visual physical simulation of fingering of acid liquid in acid fracturing crack

A physical simulation, large-scale technology, applied in the direction of measuring devices, earthwork drilling, wellbore/well components, etc., can solve the problems of low pressure difference adjustment accuracy, slow heating speed, difficulty, etc., to reduce labor intensity and increase temperature rise Effects of increased speed, mechanization and automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

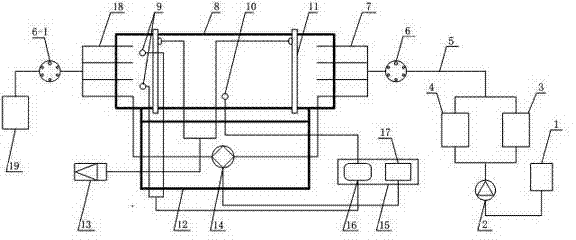

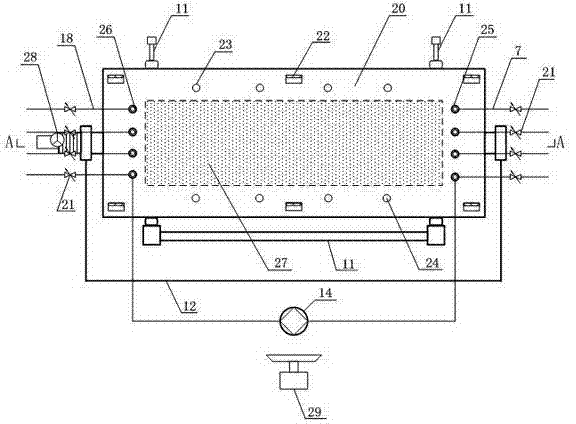

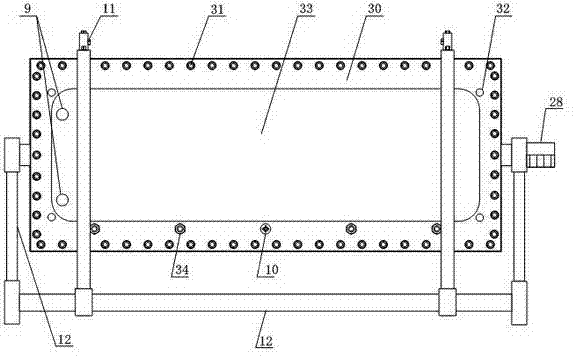

[0014] The present invention is further described according to the accompanying drawings. refer to figure 1 , figure 2 , image 3 , Figure 4 .

[0015] A large-scale visual physical simulation device for acid fingering in acid fracturing fractures, which is divided into four structural units: liquid pumping, simulated fractures, temperature and pressure monitoring and control, and image acquisition.

[0016] First, in the liquid pumping unit, the working fluid of the high-pressure constant-flow pump 2 is provided by the liquid storage tank 1, and the high-pressure constant-flow pump 2 passes the liquid in the intermediate container A3 and intermediate container B4 through the temperature-resistant and acid-resistant pipelines 5 and 6 at a constant flow rate. The through valve A6, the liquid inlet pipeline 7 and the one-way valve 21 are pumped into the liquid inlet hole 25 of the simulated fracture unit 8 .

[0017]Secondly, to simulate the crack unit 8, the stainless st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com