Dry and wet cycle climate hypergravity simulation system

A technology that simulates systems and dry-wet cycles, and is applied in weather resistance/light resistance/corrosion resistance, measuring devices, instruments, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

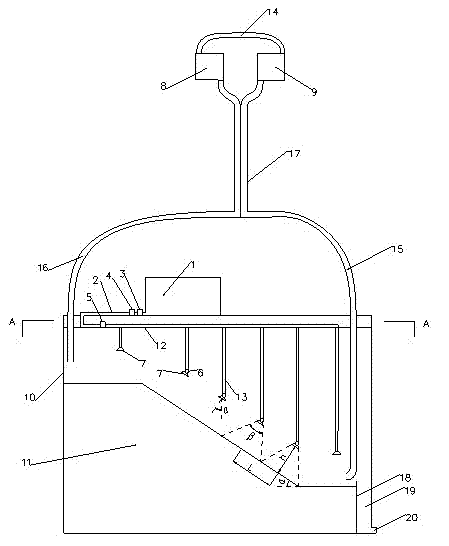

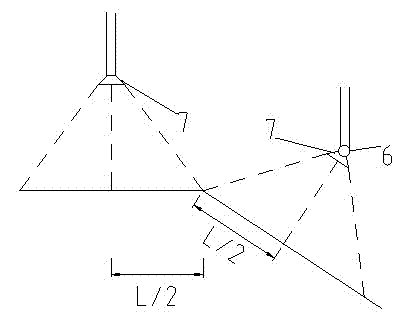

[0025] The dry and wet cycle climate supergravity simulation system of the present invention is used in a supergravity centrifuge.

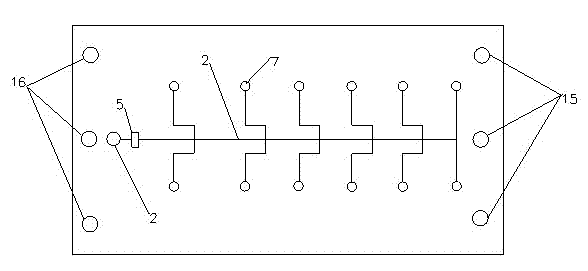

[0026] Such as figure 1 As shown, the dry-wet cycle climate supergravity simulation system of the present invention includes a supergravity centrifuge airborne model box 10, and an air heating dehumidifier 8, a blower 9 and a water tank 1 are provided outside the model box 10. The air outlet of the air heating dehumidifier 8 and the air inlet of the blower 9 are connected by an air guide tube 14, the air outlet of the blower 9 is connected with an air inlet tube 15, and the air inlet of the air heating dehumidifier 8 is connected with an air outlet tube 16. Both the air inlet pipe 15 and the air outlet pipe 16 extend into the interior of the model box 10.

[0027] The water tank 10 is fixed on the top of the exterior of the model box 10. The water tank 10 is made of metal with greater strength, so as to ensure that no major deformation or even damage...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com