Severely-polluted soil remediation device

A soil remediation and heavily polluted technology, applied in the field of contaminated soil remediation and governance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

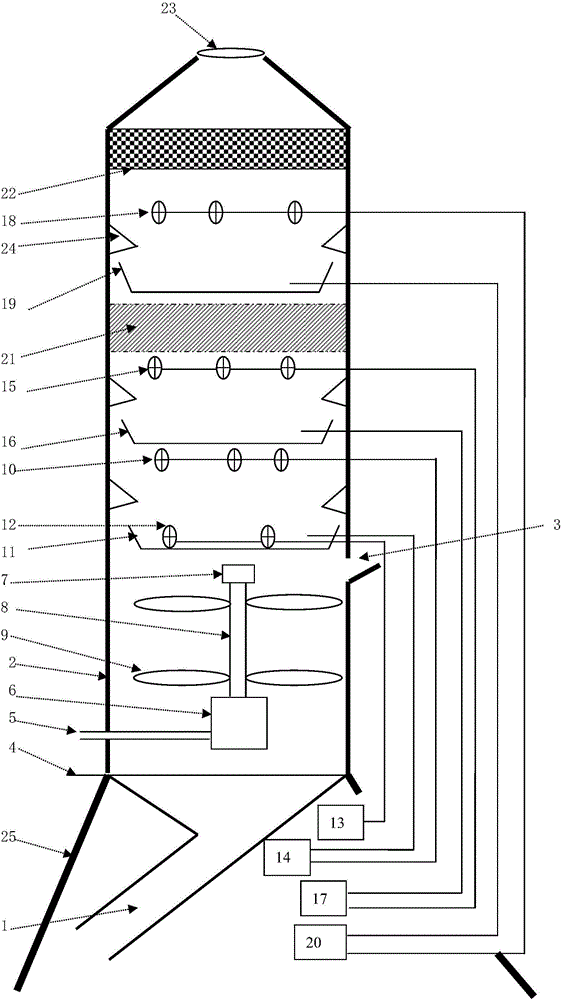

[0032] Such as figure 1 A heavily polluted soil remediation device of the present invention is shown, including soil addition and discharge system, soil heating and stirring system, volatile waste gas purification system; soil addition and discharge system, soil heating and stirring system are located in the entire heavily polluted soil remediation device The lower part of the volatile exhaust gas purification system is located in the middle and upper part of the entire heavily polluted soil remediation device.

[0033] The soil adding and discharging system comprises a soil discharging inclined bucket 1, a soil cylinder 2, and a soil adding port 3.

[0034] The soil discharge inclined bucket 1 is located at the lowest part of the soil addition and discharge system, the upper part of the soil discharge inclined bucket 1 is a conical structure, and the lower outlet is inclined to one side of the whole heavily polluted soil remediation device.

[0035] The lower part of the soil ...

Embodiment 2

[0055] The difference between the second embodiment of the present invention and the first embodiment is that the volatile substances in the soil are slightly alkaline, and there is no volatile waste gas alkalization absorption area in the heavily polluted soil remediation device, and the heavily polluted soil remediation device includes Soil addition and discharge system, soil heating and stirring system, volatile waste gas oxidation absorption area, volatile waste gas acidification absorption area, mist eliminator 21, activated carbon adsorption layer 22 and exhaust fan 23.

Embodiment 3

[0057] The difference between the third embodiment of the present invention and the first embodiment is that the volatile substances in the soil are slightly acidic, there is no volatile waste gas acidification absorption area in the heavily polluted soil remediation device, and the heavily polluted soil remediation device includes soil addition And discharge system, soil heating and stirring system, volatile waste gas oxidation absorption area, volatile waste gas alkalization absorption area, mist eliminator 21, activated carbon adsorption layer 22 and exhaust fan 23.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com